Effective supply chain planning can be the most impactful way to improve performance, boost efficiency, and strengthen your bottom line

Supply chain planning for a beverage-producing company is inherently complex. Many businesses today still rely on spreadsheets or a combination of spreadsheets, ERP, and APS solutions. However, this fragmented approach makes planning highly ineffective, as it fails to adequately address critical challenges such as long batch runs, expiration constraints, product sequencing, allergen management, batch sizes, inventory fluctuations, and storage limitations.

Spreadsheets, in particular, are not only cumbersome to manage but also make developing an optimal plan nearly impossible. As a result, production utilization suffers, inventory and storage requirements become excessive, and customer service levels may decline.

This document outlines 10 key aspects of supply chain planning that beverage producers—specifically those producing beer and non-alcoholic/soft drinks—should consider. While this guide covers both beer and non-alcoholic beverages, it does not extend to the manufacturing processes for wine and spirits.

However, in cases where beverage companies purchase bulk wine or spirits, the process of bulk wine/spirits bottling becomes relevant. Bottling may be handled by the beverage producer The beverage producer may manage bottling, but the beverage co-packing industry often plays a crucial role in this process and should be factored into overall planning.

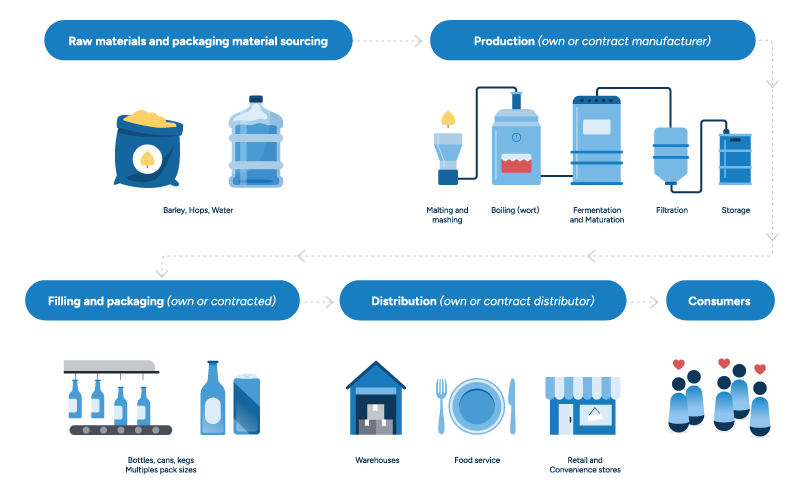

Process overview: Beer

The beer-making process involves several stages, each crucial in creating the flavors, aromas, and characteristics of the final product. Typical beer production contains the following steps:

1. Malting and mashing

The beer journey begins with malted barley, the primary ingredient that provides fermentable sugars essential for brewing. During the malting process, barley grains are soaked in water, allowed to germinate, and then dried in kilns to halt germination and develop the flavor. Once malted, the grains are crushed and mixed with hot water in a process known as mashing. Mashing converts starches in the malt into fermentable sugars through enzymatic activity, producing a sugary liquid called wort.

2. Boiling

The wort is transferred to a brew kettle and brought to a boil. Hops, the flowers of the hop plant, are added during this stage to impart bitterness, flavor, and aroma to the beer. Boiling sterilizes the wort and extracts essential compounds from the hops. The timing and quantity of hop additions affect the beer’s flavor profile, with earlier additions contributing bitterness and later adding aroma. After boiling, the wort is rapidly cooled to prepare it for fermentation.

3. Fermentation and maturation

Once cooled, the wort is transferred to a fermentation vessel, and yeast is introduced. Yeast consumes the sugars in the wort, converting them into alcohol and carbon dioxide, a process known as fermentation. Depending on the type of beer being brewed, fermentation can take anywhere from a few days to several weeks. After primary fermentation, the beer enters the maturation phase, where it develops its final flavors and aromas. This stage allows the yeast to settle and refine the beer’s taste.

4. Filtration

The beer undergoes filtration to enhance clarity and remove unwanted particles. This process eliminates yeast remnants, proteins, and other particulates that may remain after fermentation and maturation. Filtration ensures the beer has a polished, clean appearance and meets the desired quality standards.

5. Storage

Following filtration, the beer is stored in tanks under controlled conditions to stabilize its flavor and carbonation. This stage, often called conditioning, ensures the beer is at its peak quality before packaging. The storage duration varies based on the beer style, with lagers requiring longer conditioning periods compared to ales.

6. Filling and packaging

The final step in the beer-making process is filling and packaging. The beer is transferred to bottles, cans, or kegs under sterile conditions to maintain freshness and prevent contamination. Packaging formats are chosen based on the target market and distribution strategy. Labels are applied, and the beer is prepared for distribution, ready to be enjoyed by consumers worldwide.

By carefully following these steps, brewers craft a wide variety of beer styles, each with its unique flavors, aromas, and characteristics, delighting beer enthusiasts everywhere.

Process overview: Soft drinks

Water Treatment and Sterilization:

Water is filtered, softened, sterilized (for example, via UV or chlorination), and deionized to ensure purity and safety.

Syrup Preparation:

Sugar, flavors, and acids are mixed into a syrup, pasteurized to remove microbes, and checked for quality.

Blending and Mixing:

Syrup and treated water are mixed in precise ratios and homogenized for consistency.

Carbonation:

The mixture is cooled and injected with carbon dioxide under pressure, creating fizz.

10 essentials to elevating the beverage production planning process

This guide outlines 10 essential areas that require a unified, automated system where decisions are made based on facts rather than personal experience, siloed teams, and gut instinct. A system that ensures line utilization, inventory, and profits can be maximized, and revenues can be enhanced so that beer and non-alcoholic/soft drinks production can reach its full potential.

1. Tank planning

The fundamental challenge in tank planning is that each tank functions as a distinct resource with a fixed capacity. Just because a 40,000-liter tank holds 30,000 liters does not necessarily mean there are 10,000 liters of available capacity. In reality, as long as a tank contains any volume of liquid, it is considered fully utilized for planning purposes (unless top up is a possibility).

Ensuring that tank utilization is optimized based not only on volume but also on occupancy dynamics and operational constraints is the most basic and critical principle that any planning solution must account for.

Tank planning in beer production is a multi-stage process, each phase bringing unique challenges. Effective tank management is essential from the mashing stage through to the final packaging of the beer. With a limited number of tanks available at each stage—mash, fermentation, conditioning, and bright beer tanks—strategic planning is crucial to maximize capacity utilization. This level of planning requires a tool that can support multiple key concepts and constraints to ensure efficient scheduling and optimal tank usage throughout the production cycle.

Managing finite capacity is particularly critical in the beverage industry, where tank capacity management introduces unique planning challenges. One key constraint is that a tank cannot be reused until it is completely emptied and cleaned—even if only 100 liters remain in a 10,000-liter tank, it is still considered occupied and unavailable for new production.

However, there are exceptions that may require this rule to be manually overridden. One such example is “Top-Ups”, where new bright beer is added to a tank already containing the same type of bright beer. In these cases, the expiry date of the newly added batch must be adjusted down to align with the existing contents, ensuring quality and compliance.

A robust planning solution must be flexible enough to handle these standard constraints while allowing for controlled exceptions when necessary.

Another critical aspect of tank planning is recognizing that different tanks have different capabilities, making it essential to match the right tank to the right product. For example, cider production may require different types of tanks than those used for beer, necessitating careful tank allocation in the planning process.

Additionally, the flow of liquid between tanks and production processes is often constrained by the installed piping infrastructure. This means that available flow paths must be accurately modeled and incorporated into the planning solution to avoid bottlenecks and inefficiencies.

This consideration is equally important when planning filling. To prevent the overutilization of bright beer tanks, the system must account for their limited connectivity to filling lines. Typically, a bright beer tank can only be linked to one, or in rare cases, a couple of filling lines at a time. Ensuring this constraint is respected in the filling plan is key to maintaining a smooth and efficient operation.

AI models that combine heuristics and mathematical optimization allow for the simultaneous evaluation of multiple tank planning scenarios to determine the optimal solution. These models consider critical factors such as limited supply, demand fluctuations, shelf life, and various business rules and constraints, ensuring a balanced, efficient, and resource-optimized approach to tank capacity management.

2. Production wheel or cyclic planning

In the beverage industry, production processes are typically organized to run in extended batches, a strategy that helps optimize efficiency and resource utilization. Products with high consumer demand, such as popular beverages or flagship items, may be produced on a weekly basis to ensure their consistent availability in the market. In contrast, products with lower demand, such as seasonal drinks or niche offerings, might follow a more spaced-out production schedule, being manufactured every second, third, or even fourth week. This staggered approach not only meets the varying needs of the market but also minimizes production costs by avoiding unnecessary overproduction; however, it does lead to higher stock holding costs.

To implement this approach effectively, it is essential for the planning team to carefully manage and control the cadence of production for each product, determining the appropriate intervals for production based on historical sales data, forecasted demand, and inventory levels. While the sequence of production activities is typically predetermined for each cycle or period, the specific production volumes for each product may vary. These adjustments are made to ensure they align with several critical factors, including the minimum batch size necessary for operational efficiency, the actual demand for the product, and the inventory levels required to maintain a balanced supply chain.

The systematic framework that enables such precise control over production schedules is often referred to as a “product wheel” or “cyclic planning.” This approach provides a structured yet flexible way to optimize production cycles, balancing the need for efficiency with the realities of fluctuating market demands. By adhering to cyclic planning principles, beverage manufacturers can ensure that their operations remain both cost-effective and responsive, delivering the right products at the right time to meet customer expectations.

3. Planning agility and adoption

The beer industry operates within a dynamic environment characterized by constantly fluctuating supply and demand patterns. These fluctuations are influenced by various factors, such as seasonality, consumer preferences, and emerging market trends. To remain competitive, companies in this industry must address two critical needs:

- Implementation of enhanced, automated visibility tools to track both real-time and forecasted market trends

- Development of the agility necessary to swiftly adapt to these changes.

Together, these capabilities enable businesses to optimize their operations, improve responsiveness, and minimize inefficiencies.

However, many companies within the beer industry still rely heavily on outdated methods for their planning and decision-making processes. Spreadsheets, which often involve extensive manual data entry and repetitive cut-and-paste tasks, are a common tool. While spreadsheets provide a degree of flexibility, they lack the sophistication and efficiency required to handle the complexities of today’s market dynamics. In such environments, it can take weeks to adjust production and distribution plans in response to changes in demand or supply disruptions. This delay creates significant challenges, as the business is unable to react quickly enough to capitalize on emerging opportunities or mitigate risks.

Beer producers need to be able to quickly re-cut their plans in response to changes in demand and supply signals.

The consequences of these inefficiencies can be far-reaching. For example, when a company fails to respond swiftly to a sudden increase in demand, they risk stockouts, lost sales, and dissatisfied customers. On the other hand, overestimating demand or being slow to adjust production schedules can lead to an excess of unsold inventory. In the beer industry, where products are often perishable or seasonal, this surplus might end up sitting in cold storage for extended periods, driving up costs. In some cases, businesses are forced to sell this surplus at deeply discounted prices, which not only erodes profit margins but can also impact brand perception in the market.

To address these challenges, the beer industry is increasingly turning to advanced planning tools and integrated digital solutions. By leveraging automation, artificial intelligence, and real-time data analytics, companies can gain greater visibility into their supply chain and market trends. These technologies allow businesses to proactively adjust their production and distribution plans, reducing response times from weeks to mere hours or days. As a result, companies can align their operations more closely with actual market demands, minimizing waste and maximizing profitability.

Ultimately, agility and adaptation are no longer optional in the beer industry—they are essential for survival and growth in a competitive market. By transitioning from manual, labor-intensive processes to automated, data-driven systems, companies can build the resilience and flexibility needed to thrive in an ever-changing landscape.

4. Filling line optimization

One of the primary challenges faced by beverage producers is the lengthy and complex process required to switch between different liquids and packaging formats on the filling line. These changeovers, which include cleaning, setup, and configuration, can lead to significant downtime if not carefully managed. For this reason, production plans must be optimized to minimize both cleaning time and setup time, ensuring smooth transitions and higher overall efficiency.

An essential consideration in this optimization process for a beer producer is the volume of liquid held in the bright beer tank. Since beer and other liquids cannot remain in the bright beer tank for extended periods without risking quality degradation, it should ideally be emptied within a single production run. This means that the filling line will be planned based on the volume of liquid in the tank at that time rather than the demand for the finished bottles.

In addition, allergen management is another critical factor, requiring careful planning to avoid cross-contamination and adhere to food safety standards.

Another consideration in filling line optimization is the variability of bottlenecks. Bottlenecks can shift depending on the type of packaging being produced, requiring flexible planning to manage capacity effectively. Some producers measure capacity using the number of standard bottles produced per hour, as different products and packaging formats consume varying amounts of resources. Further, dry goods and storage capacity, such as the availability of bottles and cans, must be factored into the planning process.

AI-enabled solutions provide a powerful tool for addressing these complexities, offering a comprehensive approach to creating optimized production plans. Ultimately, the solution must be robust enough to address all these constraints while remaining adaptable to the unique needs of each production cycle. By adopting advanced tools and approaches, beverage producers can unlock significant improvements in efficiency, profitability, and overall operational performance.

5. The importance of demand planning

Machine learning in demand forecasting

Demand for a beverage producer is driven by a wide range of factors, including predictable seasonal trends and dynamic, short-term variables such as weather changes, holidays, or festivals. These factors often interact in complex and unpredictable ways, creating sudden surges in demand that traditional forecasting methods struggle to predict. Machine learning (ML) plays a transformative role in navigating this complexity by identifying how these variables interact—often amplifying each other’s effects rather than merely adding them up.

Unlike conventional models, ML systems continuously learn and improve by incorporating new data in real time. These systems automate critical tasks such as data cleaning, trend detection, and pattern adjustments, drastically reducing the need for manual intervention. By doing so, businesses can respond swiftly to short-term fluctuations, delivering demand forecasts that are not only more accurate but also far more flexible. This capability ensures producers can efficiently allocate resources, optimize inventory, and meet consumer needs without overproducing or missing demand spikes.

Promotion and New Product Introductions (NPI)

The beverage industry is highly competitive, characterized by frequent promotions, discount campaigns, and new product launches. These initiatives, often featuring diverse flavors, packaging styles, or sizes, significantly influence consumer purchasing behaviors. Accurately analyzing the impact of these activities is challenging for planners, as they involve qualitative data like promotion type, timing, and advertising channels—factors that traditional forecasting models cannot easily quantify.

Machine learning addresses these challenges by processing vast amounts of complex data to uncover hidden patterns, correlations, and trends. For instance, ML can identify and measure the effects of cannibalization, where a new product or promotion detracts from the sales of an existing one. This ability enables producers to evaluate the true profitability of promotions, avoid inefficiencies, and minimize waste. By quantifying the intricate interplay between promotions, new products, and consumer behaviors, ML provides the insights necessary for more effective planning and accurate forecasting.

The impact of improved forecast accuracy and accountability

Enhancing forecast accuracy and fostering accountability in the beer industry offers substantial benefits across efficiency, profitability, and sustainability:

- Forecast accuracy: Precise demand forecasts empower producers to optimize production schedules, inventory management, and procurement. This minimizes waste, reduces costs, and ensures resources are allocated efficiently, ultimately preventing issues like overproduction or stockouts.

- Forecast accountability: By holding forecasters accountable for the quality of their predictions, organizations foster a culture of continuous improvement in forecasting processes, models, and methodologies. This not only boosts forecast reliability but also enhances resource utilization and decision-making.

Collaboration and operational efficiency

Improved demand planning driven by machine learning also significantly benefits collaboration and workplace harmony. Accurate and reliable forecasts reduce the friction and chaos often associated with reconciling conflicting data from multiple departments. Rather than struggling to align disparate versions of spreadsheets, teams can work together from a unified, seamless source of information. This shared understanding fosters collaboration, streamlines decision-making, and ultimately boosts job satisfaction.

By leveraging machine learning, the beverage industry can achieve transformative improvements in demand forecasting. From more efficient resource allocation to better collaboration, ML-driven demand planning enhances operational performance and supports long-term profitability and sustainability.

6. Leadership enablement through transparency

Beyond optimizing the entire supply chain—from tank planning to filling lines and storage—enhanced visibility allows for a stronger focus on managing exceptions rather than simply gathering data.

While “visibility” is often a broad term, in this context, it is driven exclusively by digitization and automation. It encompasses critical areas such as customer service, ingredient management, capacity planning, labor allocation, warehousing, third-party logistics (3PL) utilization, shelf-life monitoring, and all other elements essential for an optimized supply chain. Effective planning is impossible without visibility, and relying solely on human observation provides only a limited perspective.

Many companies currently operate their supply chains using disparate, siloed spreadsheets. In contrast, true visibility should offer a comprehensive, real-time view of all supply chain components over the entire planning horizon.

For beverage producers, the planning horizon varies based on production capacity, market demand, and operational requirements. The approach can differ significantly between non-alcoholic beverage manufacturers and beer producers. For beer producers, typical planning horizons are structured as follows:

For beer, the tactical planning horizon amounts to around 2 – 52 weeks, with companies understanding where they will be across key parameters at each stage of that horizon.

Those parameters relate to production capacity, tank capacity, and whether more resources need to be added. They also include inventory levels, storage levels, expiry issues, and distribution requirements. The supply of ingredients and packaging for different products also needs to be visible across this period.

Without a solution that provides end-to-end visibility of the above, the result is a very reactive process that leads to costly errors such as too much inventory, a race to clear excess stock at lower prices, and a mismatch between supply and demand.

A system with one clear source of fact-based analysis enables and strengthens leadership, resulting in faster and more accurate decisions, more concise and rapid information relayed to customers, and a consistently clear view of how real-time plans are impacting the bottom line.

7. Demand prioritization

In supply chain planning, the ability to prioritize customer demand and implement fair share distribution during stock shortages is critical to maintaining both operational efficiency and strong customer relationships.

Prioritizing demand (forecast and customer orders) ensures that high-value or strategically important customers receive the products they need.

At the same time, fair share distribution provides an equitable approach to allocating limited inventory across customers, minimizing dissatisfaction, and maintaining trust when demand exceeds supply. These capabilities enable businesses to navigate supply constraints with transparency and agility, ensuring that resources are allocated strategically while minimizing the risk of losing key customers or damaging brand reputation. Integrating these functionalities into supply chain planning systems allows for informed decision-making and supports a balanced, customer-focused approach to inventory management.

While prioritizing demand is crucial, it is equally important to maintain an optimized production plan by accounting for factors such as tank size, batch size, filling line capacity, changeover complexities, and material constraints. Rather than enforcing demand prioritization as a rigid constraint, treating it as a weighted penalty allows the optimization process to strike a balance. This approach enables the system to fulfil prioritized demand while still considering broader supply chain variables, ensuring efficiency and flexibility across the entire production and distribution network.

8. Improving inventory management

Effective inventory management is crucial for maintaining operational efficiency, reducing costs, and enhancing customer satisfaction. By ensuring the right products are available at the right time, businesses can minimize stockouts, avoid overstocking, and reduce carrying costs. A well-managed inventory system improves cash flow, streamlines supply chain processes, and supports informed decision-making, ultimately driving profitability and competitive advantage.

Among the important functional aspects that should be considered as part of an efficient set-up are:

Optimal safety stock

Insufficient stock can lead to lost sales and damage a company’s standing, while excessive inventory incurs unnecessary holding costs. Safety stock serves as a critical buffer against unexpected fluctuations in demand and supply, helping to strike the right balance, ensuring customer orders are fulfilled, and safeguarding both sales and reputation.

Traditionally, safety stock is determined based on a fixed number of days of coverage, often relying on limited analytical insights. However, modern approaches leverage mathematical modeling and optimization to refine safety stock levels. By incorporating variables such as demand variability, forecast accuracy, supply lead times, lead-time variances, holding costs, missed demand costs, and minimum batch sizes, businesses can tailor safety stock to their unique operational needs.

This data-driven method enables precise calculation of optimal safety stock levels, maximizing working capital efficiency. Moreover, advanced technologies allow safety stock to dynamically adjust over time, responding to changes in forecasted demand and accuracy for ongoing adaptability and resilience.

Optimal stock distribution

Optimal stock distribution is a cornerstone of effective inventory management. It ensures that products are positioned at the right location, at the right time, and in the right quantity to meet demand efficiently. This is particularly critical in the beverage industry, where finished goods are bulky, leading to elevated storage costs.

To address these challenges, many beverage companies turn to third-party logistics (3PL) providers for storage and distribution. While 3PL solutions help reduce the need for extensive in-house warehousing infrastructure, they require careful planning and coordination to avoid inefficiencies and minimize additional costs.

When designing an optimal supply chain plan, factors such as inventory costs, storage costs, and storage capacity must be considered. A robust supply chain planning model must allocate inventory strategically across the network, ensuring efficient resource utilization while maintaining the ability to meet customer demand.

By integrating these considerations into stock distribution strategies, businesses can achieve a balance between cost efficiency and operational responsiveness, securing a competitive advantage in the marketplace.

Expiry and slow-moving and obsolete (SLOB) considerations in inventory management

Effective inventory management includes addressing slow-moving and obsolete inventory (SLOB) as well as managing product expirations. Proactive strategies such as timely price markdowns and targeted promotions are essential to maximizing the value of goods while minimizing waste. Early intervention prevents rushed, last-minute decisions that can lead to unnecessary losses or missed opportunities.

Integrating expiry and SLOB considerations into a comprehensive supply chain planning model ensures that products are sold before expiration, supporting optimal profitability and operational efficiency. This holistic approach is key to reducing waste, enhancing value recovery, and maintaining a resilient inventory system.

Inventory management still holds the key to numerous opportunities to lose or gain efficiency and revenue.

9. Running scenarios

The ability to run scenarios can be very important when preparing for an efficient supply chain. . What-if scenarios, that measure the impacts of adding new dimensions to the process, are an essential part of supply chain decision making.

A new product, a new market, a new warehouse, a new 3PL provider, additional production lines, or brewing capacity – the temptation for businesses to instinctively channel profits into investments and scale at pace is understandable. However, the beverage industry is fraught with examples where expansive – and expensive – decisions have played out poorly or proven to be a stretch too far and too quickly.

Scenario planning capability ensures that the ‘new’ is considered and delivered at a scale that generates maximum value. Moreover, it is important that these scenarios are clearly presented through a dashboard that encourages users to make the right decisions from the information available.

Running various scenarios allows beverage producers to test different outcomes and strategies. It represents a much more proactive approach that helps optimize operations, anticipate challenges, and make informed business decisions.

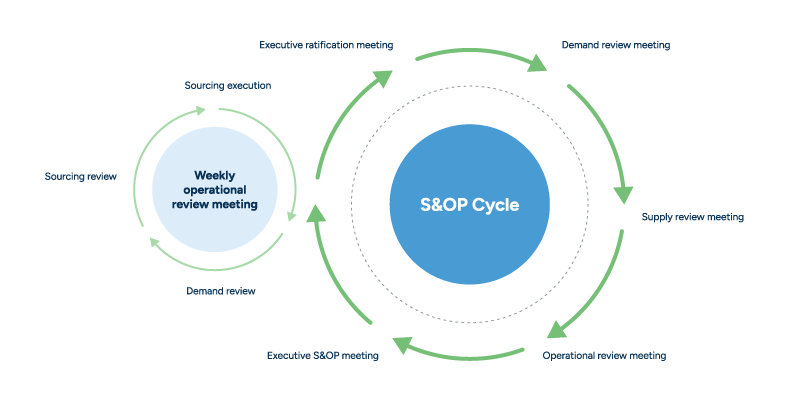

10. Establishing an S&OP framework

Sales and Operations Planning (S&OP) is a critical process for all beverage producers due to the industry’s complexity and the need to balance supply with fluctuating demand. The S&OP process creates an understanding across the entire supply chain of why certain decisions are made, and it removes organizational silos.

To enable a solid S&OP process you need essentially two things:

- A system that will provide all (or at least most) of the answers to the questions that the S&OP process needs. The information needs to be provided accurately and automatically.

- A well-defined process.

Below are the key steps to establish an S&OP process:

Step 1: Defining the planning horizon

Each company will have a different planning horizon based on their own specific challenges and customer portfolio. It’s important to begin by defining your own.

Step 2: Defining the S&OP and S&OE process

A meeting card for each review meeting must be established, covering several key aspects. These include what the review meetings should consist of, their frequency, who will chair and attend them, the desired outputs, the necessary inputs, and the governance process to ensure all of the above is adhered to.

Step 3: Defining input questions

There will be certain questions that S&OP requires answers for in each meeting. It’s important to list these questions ahead of time, assigning different talking points to the different stages of the planning horizon. Examples of key questions would be, “Do we have enough capacity? Are we holding too much stock? What are the projected shortages? How much surplus can we expect?”

Step 4: Defining the governance process

As referred to in Step 2, the chosen process and timelines need to be underpinned by an effective governance model—a set of rules and consequences that ensures everyone follows the process. It is important that there is an overarching process that will identify and rectify any non-adherence to the defined process.

Effective S&OP complements all other strands related to greater visibility and clarity of decision-making. It enables more fact-based leadership decisions and supports the role of digitized scenario planning.

By following this framework, you can ensure everyone is singing from the same hymn sheet to get the most out of your S&OP.

Crafting precision and brewing success: Elevate your beer supply chain planning with RELEX

Streamline your operations, optimize inventory, and meet demand with precision. From raw ingredients to the final pour, our advanced supply chain solutions ensure every step of your beer manufacturing process is efficient, responsive, and tailored for success. Cheers to smarter planning and smoother brewing!