The term “AI” has some of us rubbing our temples and praying for peace and quiet. AI fatigue doesn’t just stem from the cacophony surrounding it; it’s due in large part to the fact that it’s all chatter and no substance. No one is defining and outlining practical uses for it. With more and more companies claiming they are “AI-powered,” the array of options confuses the matter and makes it difficult to know where to focus investments.

This AI overload snares business leaders in a tug-of-war between the risk of investing in the wrong technology and the risk of being left behind. They need solutions that will help meet customer demand and protect margins, but they are understandably hesitant to invest in untried, unproven AI. They want to improve accuracy and efficiency, but they are reluctant to automate processes that directly affect customer service or might inhibit the competitive advantage gained from human expertise.

But in the meantime, AI would really come in handy to address pervading market challenges like disruptions, demand volatility, talent shortages, data issues, and planning roadblocks.

Cut through the noise

Retailers, wholesalers, and CPG companies need a technology partner who has already developed the right AI solutions for their industries and who understands that innovation is not a one-time deal.

At RELEX, we’ve been at this a long time, building up our AI expertise, a network of partnerships, and a suite of AI-driven solutions that deliver tangible business benefits to companies every day.

To keep ahead of technology trends and pass that advantage on to our customers, we invest 25-30% of our revenue back into R&D to accelerate our development cycles.

This helps us live up to one of our core values: “Put an end to stupid things.”

We believe stupid things include talking about AI without discussing the specifics.

So let’s talk specifics.

Our approach: How AI diversification makes the most of your investment

AI is not a monolith. It is not a one-size-fits-all solution, and there isn’t just one type of AI. The key to successful retail and supply chain planning is what we at RELEX call “AI diversification.”

AI diversification involves investing in different types of AI that perform distinct functions while operating collaboratively for optimal efficiency and profitability. It’s making sure you use the right tool for the right task, and it’s the best way to safeguard your investment in technology. On one hand, you don’t get fixated on flashy AI trends that blind you to the advantages of quieter – but just as powerful – AI capabilities. On the other hand, you’re integrating innovations as they become available, so you don’t lose your competitive edge.

A solution suite that provides this portfolio of AI functions drives rapid ROI and makes it easy to maintain and scale your AI toolkit so you can continue to realize a return on investment far into the future.

The components of AI diversification

AI diversification is built on a three-part structure:

- Specialized AI

- Gen AI

- An AI-enabling platform

By developing and integrating these building blocks, RELEX has helped companies thwart external challenges like market volatility and overcome internal obstacles like poor data and lack of collaboration.

Let’s delve into the mechanics and benefits of each component.

Specialized AI

Specialized AI uses optimization capabilities and machine learning (ML) technology to perform highly specific tasks with superhuman speed and accuracy.

RELEX has been implementing specialized AI since long before the recent AI mania. In fact, all our customers already use it to cure modern supply chain headaches. Specialized AI has replaced spreadsheets and legacy planning systems that couldn’t keep up with data requirements and increasing complexity. Unlike generic approaches, it’s tailored to industry-specific challenges, providing powerhouse calculations that hone processes like forecasting, inventory optimization, production planning, promotion planning, and workforce management.

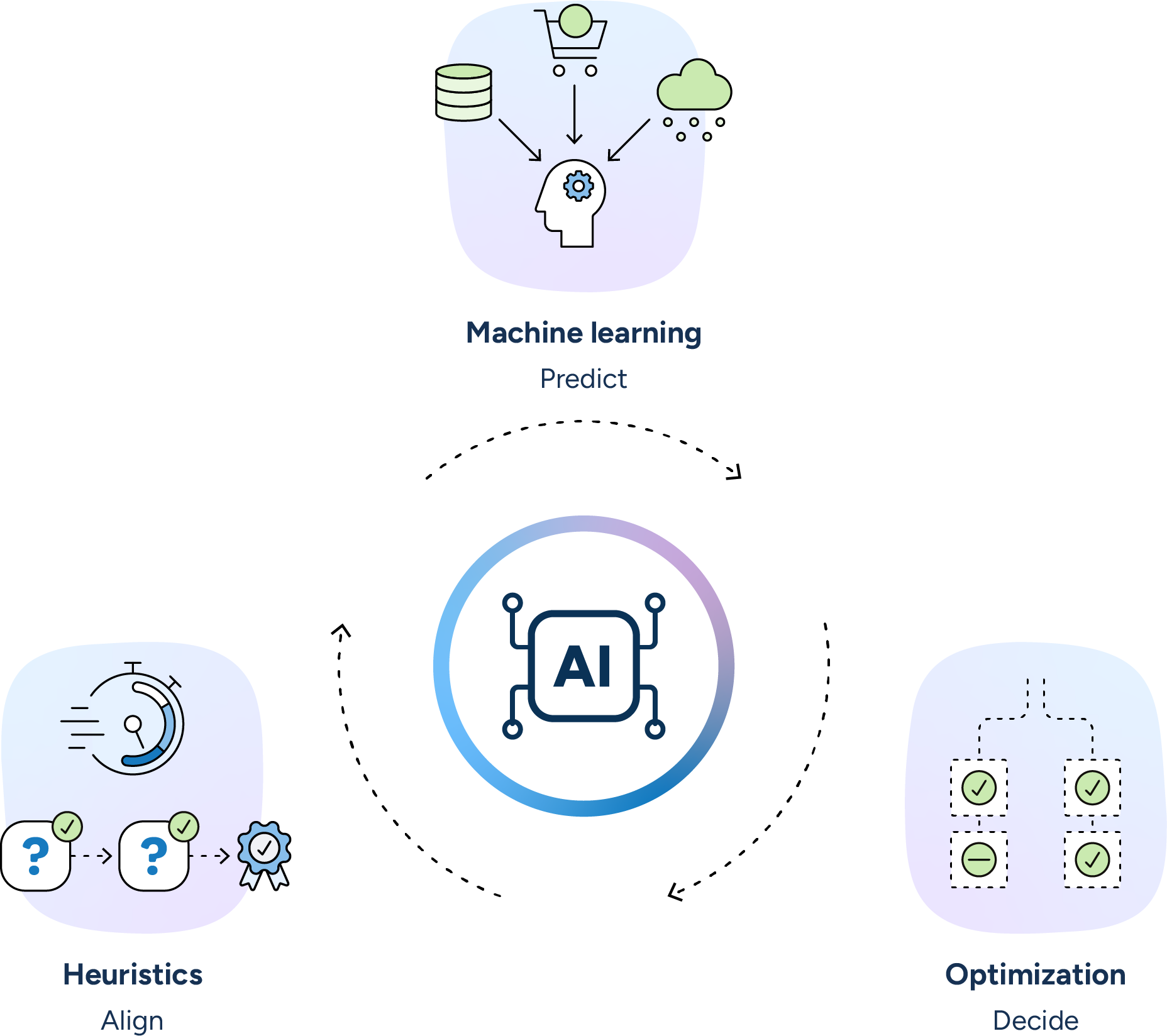

Our specialized AI capabilities break down into three types: machine learning, mathematical optimization, and heuristics.

Machine learning is an advanced subset of AI that uses algorithms to analyze enormous data pools, generate output, and examine outcomes, looking for opportunities to improve accuracy.

In ML-based forecasting, for instance, ML algorithms assimilate supply chain information rapidly and analyze it for patterns, generating the forecast and reviewing inventory performance to fine-tune and improve calculations continually.

Across industries, these algorithms can incorporate recurring sales patterns, internal business decisions, and external demand factors, lifting the burden from human planners who would otherwise be unable to process and analyze the sheer amount of supply chain data generated.

Mathematical optimization considers all available options to determine the action that makes the best possible tradeoffs between conflicting requirements to achieve KPIs.

Complex environments in which multiple objects and constraints need to be balanced are prime candidates for optimization.

For example, a CPG company or distributor may use optimization to analyze demand forecasts, transportation costs, and storage capacities to determine the most cost-effective shipment options that still meet customer SLAs.

Heuristics are rules-based engines that answer a set of questions, one at a time, eliminating options that do not directly serve specific objectives.

In simpler supply chain networks, heuristics are great for generating rule-of-thumb calculations fast.

For instance, a wholesaler with steady demand and a less complex distribution environment may set a rule to reorder products when inventory dips below a certain minimum, ensuring availability without complicated analytics. Heuristics are also a great method for kicking off rough-cut capacity plans that can later be refined with optimization.

These capabilities work together to optimize planning outcomes. Machine learning models predict demand. Optimization balances requirements for data-fueled decisions. Heuristics provide fast answers in simple scenarios to keep goods flowing smoothly through the network.

The takeaway: Specialized AI rapidly analyzes massive amounts of data and refines calculations over time for more responsive, industry-tailored planning processes that improve accuracy, customer satisfaction, and profitability.

Want a deeper dive? See more practical examples of how specialized AI works.

Gen AI

In the business world, gen AI (or “generative AI”) usually refers to large language models (LLMs) that synthesize and communicate data in easily digestible ways.

Companies have a lot of big questions about this emerging technology:

- “How can I apply gen AI right now while prepping for future capabilities?”

- “How can I ensure continued ROI when the technology is still developing?”

- “How can I easily integrate it across my planning suite?”

There has been a lot of hype and fanfare but not a lot of answers – until now.

At RELEX, we’ve developed Rebot – the first supply chain gen AI assistant on the market. Rebot is plugged into the RELEX knowledge base, which houses our documented best practices. We continually update this living repository with our latest developments and learnings. Supported by this, Rebot can both answer general supply chain questions and provide solution-specific assistance, quickly filling in knowledge gaps for a better user experience.

Rebot has answered over 100,000 queries since its launch in 2023, and our customers are already reporting productivity gains like:

- Accelerated onboarding that requires fewer resources.

- Easier, more efficient daily operations.

- Better adoption and understanding of the RELEX solution.

Rebot is only getting warmed up. Eventually, this copilot will be integrated throughout the RELEX solution for a seamless user experience. It will be able to generate custom, company-specific insights by referencing customer data (without ever storing or training on it so that the information remains secure and under customer control). Rebot will play a more collaborative role, providing users with a deeper understanding of their supply chain and recommending actions for better decision-making.

The takeaway: As a best practice and solution information resource, Rebot already delivers value through continuous learning opportunities. RELEX is actively developing it into an insight-rich copilot that collaborates with teams to initiate plans, helping them focus on exception management and improve KPIs like sales, margins, availability, and spoilage.

The RELEX platform

Companies are scrambling to take advantage of AI developments, but how can they effectively integrate them into their planning functions? Many companies are in danger of selecting AI applications…and then having no way to maintain them or weave them into current processes.

What’s more, AI is a major investment at a time when companies need to protect margins. How can decision-makers identify the right solution to accelerate ROI and support long-term profitability?

A successful AI implementation can’t be static or siloed. It needs to incorporate technological advancements easily, and it must seamlessly interact with data and other planning functions.

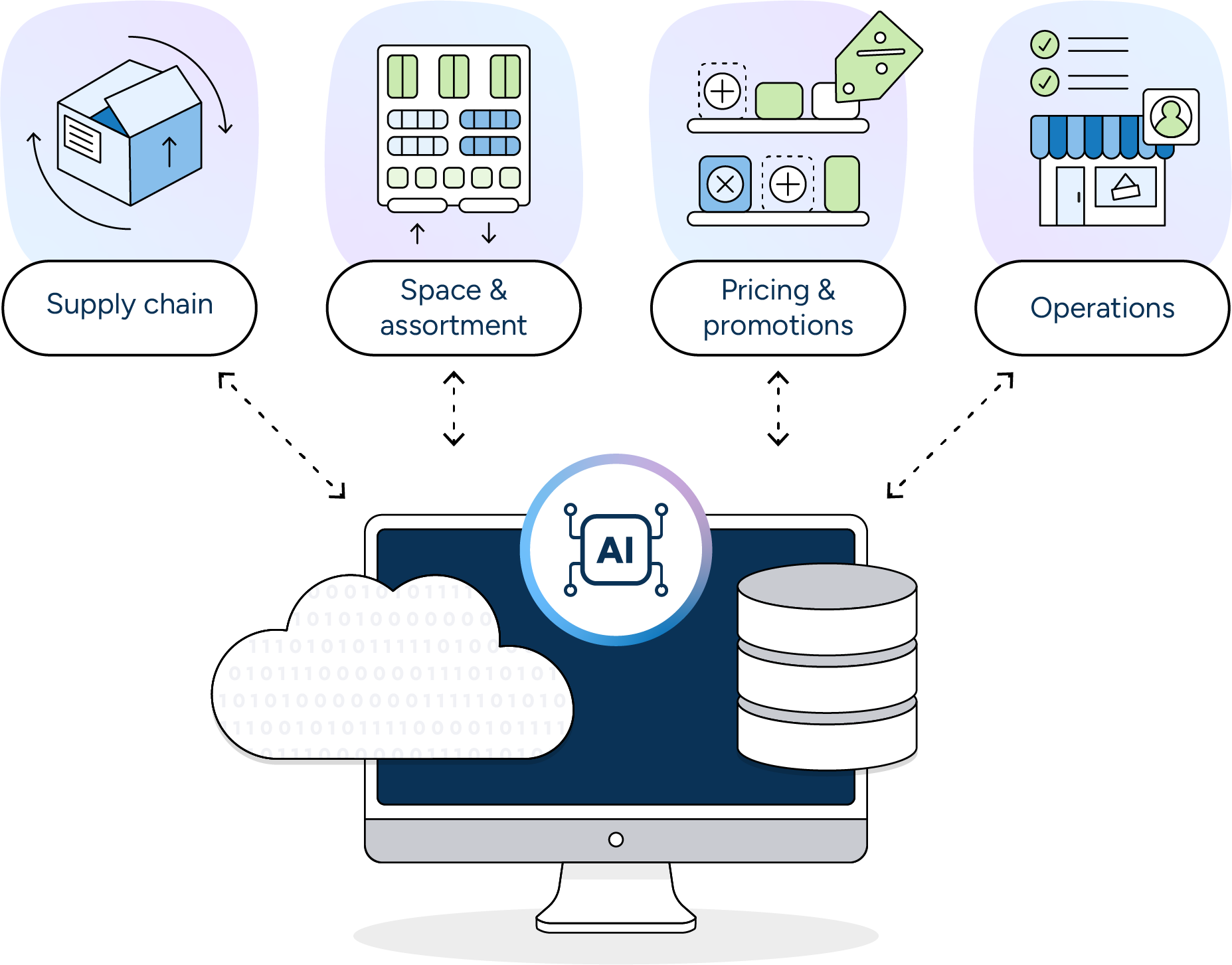

An AI-enabling platform is a single, secure, data-rich platform that unites AI capabilities across planning functions, supports continuous tech enablement, and provides access to the latest AI tools to unlock value at scale.

The RELEX platform is specially designed for optimal performance and scalability:

- The platform hosts all our AI-supported planning functions for better visibility, collaboration, and accuracy.

- These functions pull from a single database for smoother data sharing, keener insights, and continually refined AI calculations.

- The platform integrates the latest technology from both RELEX and our partners (like Microsoft) so our customers can easily incorporate innovations into their daily processes.

The takeaway: The RELEX platform maximizes and sustains the return on tech investments through cross-functional collaboration, easy data sharing, and the continual integration of the latest AI developments. This gives companies the stability, scalability, and protection against inevitable market surprises to remain profitable and efficient.

Details matter: How RELEX makes the most of data

RELEX trains our algorithms on decades’ worth of CPG and retailer data, from ice cream manufacturers to DIY retailers. This means that even at a base level, these algorithms are honed to understand the nuances of each industry. With this foundation, they can then improve calculations on a network-specific level.

Moreover, thanks to the shared data pool, the AI is better trained, translating to better planning across the solution. For example, more accurate ML-based demand forecasting helps planners tailor replenishment plans and design more effective space planning.

Read more: The IT playbook for successful data management in retail planning

How RELEX conquers data challenges

As with any AI, performance is incumbent upon data quality. “Garbage in, garbage out,” as the saying goes.

The catch is that supply chain data is often…messy. Across industries, companies struggle with data gaps and inaccuracies.

RELEX uses machine learning to clean up that data.

For instance, among the many techniques RELEX uses to overcome data issues are level shift detection and outlier detection. Level shift detection helps identify major step changes in demand, while outlier detection prevents unusual sales spikes or drops from distorting forecasts. Both capabilities help forecast solutions calibrate appropriate responses to demand anomalies.

Watch: Unlock the future of supply chain with AI

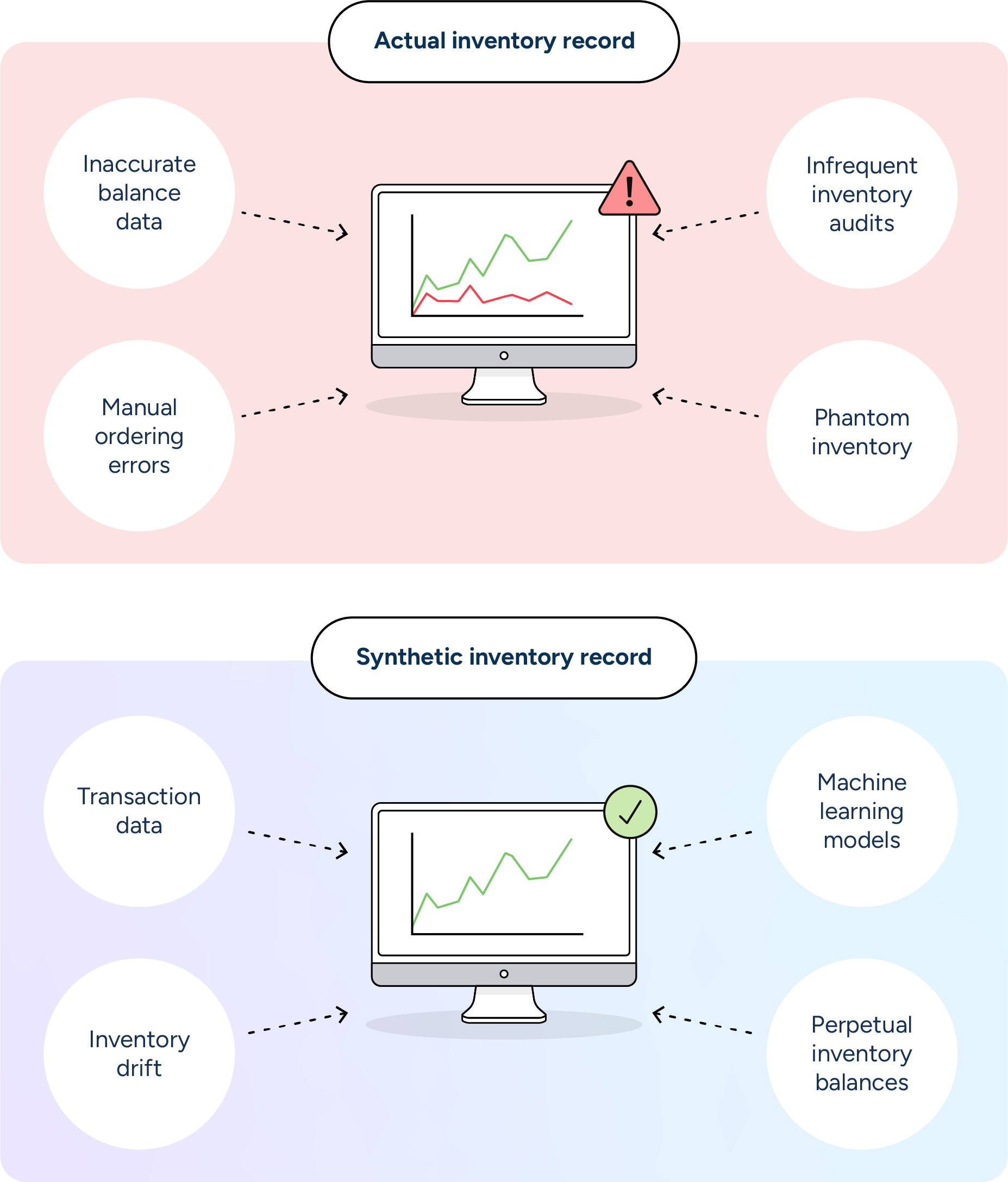

But sometimes, the data situation is more dire. There are major gaps or unseen mistakes in the inventory balance counts, leading to poor replenishment and inventory management. In this instance, one of the most powerful examples of data quality control is predictive inventory.

Predictive inventory uses machine learning to estimate and correct inventory inaccuracies by analyzing sales and transaction data and estimating factors like spoilage to create a synthetic view of inventory. This synthetic record is more accurate and reliable than the often error-prone store inventory counts, helping companies sidestep poor or non-existent balance data – a particular advantage when planning fresh produce.

Real-world benefits of AI diversification

By equipping companies with AI-diverse planning solutions, RELEX has helped retail and supply chain professionals extract valuable insights from their data, enhance collaboration and end-to-end visibility, and scale their businesses amid choppy market conditions.

With the RELEX approach, our customers have achieved:

- Faster ROI for reinvestment in growth opportunities

- Maximum cost savings and sustained profitability

- Increased efficiency for reduced waste and more sustainable supply chains

- A scalable, surprise-immune tech stack

Among these many success stories is One Stop, a leading UK convenience store chain. One Stop uses machine learning to manage their ultra-fresh products and weather-sensitive items while avoiding promotion-associated cannibalization.

“RELEX machine learning drove an immediate improvement to forecast accuracy that we felt throughout the supply chain and store and DC operations.”

“You simply can’t overstate the value that AI-based forecasting brings to the retail environment,” said Richard Turton, Head of Supply Chain at One Stop. “RELEX’s machine learning drove an immediate improvement to forecast accuracy that we felt throughout the supply chain and store and DC operations.”

The company drove an 8.5% improvement in ultra-fresh product availability without a significant spike in spoilage rates and increased availability across its entire assortment, contributing to a significant sales increase.

One Stop is not alone. With a customer NPS score of 60 (above the industry average), RELEX has a proven track record of helping companies deploy the right AI technology to solve their industry- and business-specific problems.

“We were particularly impressed by their advanced, AI-driven approach and the flexibility of their inventory management systems.”

Camille Fratanduono, Senior Vice President of Inventory, Replenishment and Planning at Lowe’s, explained why the DIY giant chose to collaborate with RELEX and its partner Accenture: “Our selection of RELEX was driven by their proven expertise in the home improvement retail sector. We were particularly impressed by their advanced, AI-driven approach and the flexibility of their inventory management systems. RELEX is well-known for their automation capabilities and their exceptional dashboard. Working with both RELEX and Accenture aligns with our ongoing commitment to leveraging innovative solutions to enhance our business processes.”

Other companies, like JYSK, were among those who had machine learning initiatives built into their business objectives.

“We wanted to make sure that we had a scalable solution, that we had good user interfaces, a high forecasting quality, and, last but not least, we wanted to introduce machine learning as a component in our demand planning process,” said Heine Sort, Flow of Goods Director.

Sort explained, “After a diligent selection process, RELEX was chosen because of the solution’s flexibility, which enables JYSK to be in full control of the process while benefiting from forecast improvements using state-of-the-art AI and machine learning.”

Learn more about how companies across industries and around the globe have tackled sticky supply chain problems with RELEX AI technology.

Explore more customer AI success stories.

Looking ahead: Building a diverse AI portfolio

AI may seem a nascent field, but at RELEX, we’ve been refining our AI capabilities for years, constantly evolving to maximize value for our customers. Our full suite of AI-powered solutions is calibrated to outmaneuver industry obstacles, taking a targeted approach to challenges throughout retail, wholesale, and manufacturing to drive profitability and maintain healthy supply chains.

Want a detailed look at more retail and supply chain use cases?