Are you wasting time and money on a poorly integrated supply chain?

Oct 31, 2018 • 4 min

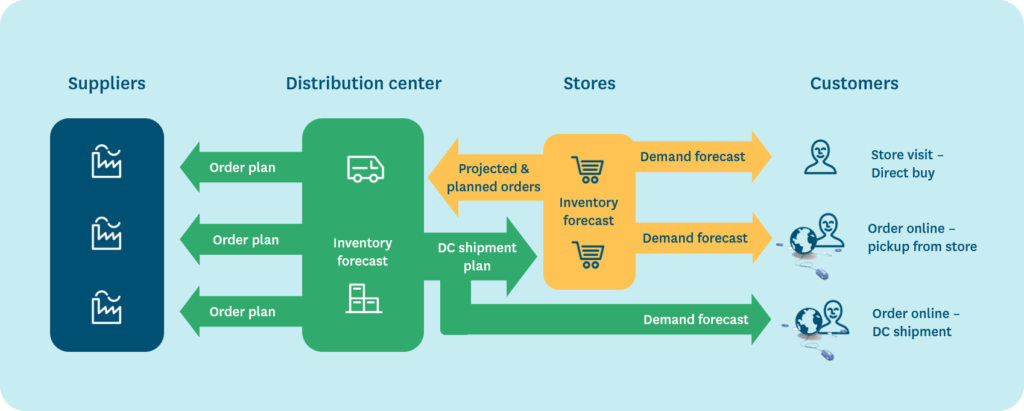

Traditionally, store replenishment and inventory management at the regional distribution centers or central warehouses have been separate processes, driven by separate demand forecasts.

In a recent survey, we found that 16 % of large US grocery retailers still base their distribution center forecasts on historical data on outbound deliveries from these distribution centers. This is akin to driving a car while looking into the rearview mirror.

According to the same survey, a clear majority of retailers – 70 % of the respondents – have chosen the more forward-looking approach of basing their distribution center forecasts on store demand forecasts. Granted, this is a better approach than only looking at outbound deliveries.

There are, however, some important disadvantages to using store demand forecasts to drive planning at the distribution centers:

1. Goods need to be delivered to the stores before the stores can sell them. This means that the distribution center forecast needs to go up before the stores’ demand forecasts go up and vice versa. The difference in timing depends on the stores’ sell-through rates and replenishment schedules, which means that the difference in timing varies between stores and products and sometimes also weekdays. The result is that it is almost impossible to accurately account for the difference in timing, which is bad news for your forecast accuracy at the distribution centers.

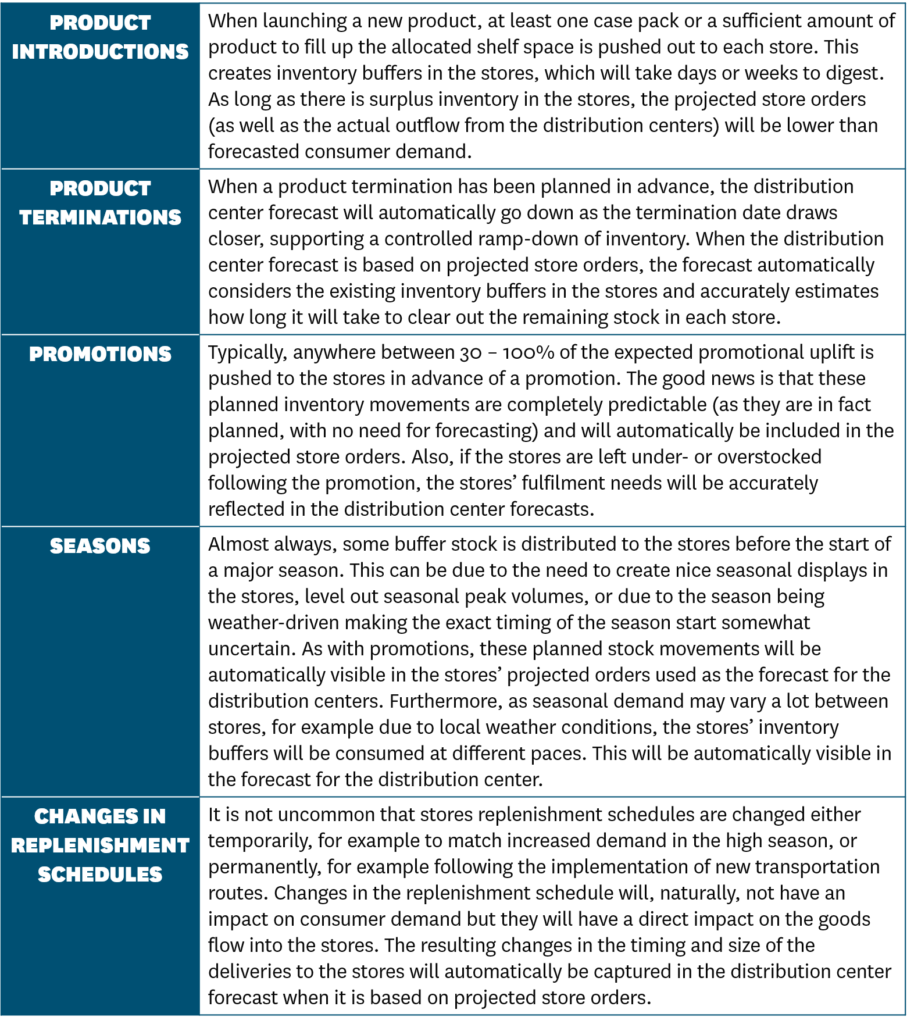

2. When goods are pushed rather than pulled through the supply chain, there will be outbound delivery peaks at the distribution centers which are not visible in the stores’ demand forecasts. A typical example is promotions, where anything between 30 % – 100 % of the expected promotional uplift needs to be delivered to the stores before the promotion starts. The promotion, thus, causes a much bigger demand peak at the distribution center than in the stores. This peak is fully controlled by the retailer itself, but still requires a lot of manual planning work or “guesstimating” when the supply planners at the distribution center try to anticipate when and in which quantities stores will take in the promoted products.

Many of the situations that are considered most difficult to tackle in the distribution centers, such as building up stock in stores in anticipation of promotions and seasons, are situations which are fully controlled by the retailers themselves.

It is quite ironic that many of the situations that are considered most difficult to tackle in the distribution centers, such as building up stock in stores in anticipation of promotions and seasons, are situations which are fully controlled by the retailers themselves.

Supply Chain Projections Enable Seamless Integration

Best practice is to base distribution center forecasting on the stores’ projected orders, which reflect both pull-based demand as well as planned, push-based stock movements. According to a recent survey, only 14 % of the responding North American grocery retailers have implemented this.

To achieve seamless integration of store and distribution planning, the planning system needs to be able to calculate projected store orders per product, store and day several months or even a year into the future reflecting current and known future replenishment parameters as well as the demand forecast. These calculations, of course, require significant data processing capacity, which is likely to be one explanation for the surprisingly low adoption rates.

In practice, the stores’ order projections consolidate data on the stores’ current inventory, safety stocks and visual minimums, replenishment schedules as well as any planned inventory movements, such as stock being pushed into the stores before big promotions.

When the order projections are aggregated across stores, they form very accurate, customer-driven forecast for the distribution centers.

When the order projections are aggregated across stores, they form very accurate, customer-driven forecast for the distribution centers.

Below are some examples of situations in which the value of basing forecasting at the distribution centers on projected store orders is especially notable.

An Integrated Supply Chain Removes the Need for Double Planning Work

The impact of planned changes in store replenishment are automatically reflected in the projected store orders forming the demand forecast for the distribution centers. This means that as soon as promotions and the corresponding stock-ups in the stores are planned, their impact will automatically be visible in the distribution center forecast on the right dates and in the right quantities. The same, of course, goes for seasonal planning, assortment changes, changes in replenishment schedules and so on.

Of course, having the right functionality and data processing capabilities in your planning system are key enablers, but the real challenge is getting the whole organization to work more proactively. Ensuring that decisions are made early enough, but not too early to unnecessarily reduce flexibility in a dynamic market, requires that everyone in the organization has a basic understanding of how the supply chain works and what the relevant lead times for different types of changes are.

So, do you have a good reason for not integrating your supply chain?

This blog post is part of a more comprehensive guide: ‘Best Practices for Managing Grocery Retail Supply Chains‘. The guide highlights key approaches for increasing both responsiveness and efficiency in grocery supply chains, including chapters about AI in demand forecasting, store replenishment, DC inventory management, capacity planning and more.