1. Why the Business Case is Critical to Drive Forecasting and Replenishment Technology Investments

Retail is undergoing a rapid digital transformation. New technologies are emerging faster than ever, unlocking new benefits in all facets of the business. This is especially true in supply chain management, where ever-evolving customer behavior changes, the creation of new sales and fulfillment channels, and an endless string of disruptive events mean that manual processes have become completely ineffective. Leading retailers, those who strive to innovate their supply chain, operate at a much higher level of efficiency, speed, and accuracy than the laggards in their industry.

New technology, however, requires significant investment. How can you, as a retailer, know that you are looking at the right solutions, basing your evaluations on the best possible estimations for costs and benefits, and ensuring that your investment in forecasting and replenishment technology will ultimately pay off?

The best way to address these concerns is by creating a business case and calculating the potential ROI for the supply chain technology investment. A business case enables you to evaluate a potential investment based on its expected benefits. It highlights the core value drivers for your business, helps you separate must-have features from nice-to-have features, and facilitates internal communication and organizational buy-in. Finally, if you decide to move forward with the investment, the business case enables you to set clear goals for your technology implementation.

2. Building the Better Business Case: Family Hypermarket’s Supply Chain Starting Point and Improvement Needs

To demonstrate best practices for building a business case and put perspective on some of the primary considerations when working with return on investment (ROI) calculations, this guide will follow a fictional model retailer, “Family Hypermarket.”

Family Hypermarket is a $5 billion general merchandise and grocery chain based in the United States. They operate 100 stores and five distribution centers, carrying an average of 40,000 SKUs per store. Family Hypermarket is also experiencing rapid growth in their online channel and offer fulfillment from DCs as well as the option to buy online and pick up in store (BOPIS).

2.1 Assessing the Current State of Forecasting and Replenishment

Too many retailers lack an accurate picture of their business as a whole. Building a business case for a supply chain technology investment is about more than just the technologies and tools. It’s vital to understand where you are today before you try to put together a plan for where you want to go.

Let’s take a closer look at Family Hypermarket’s current supply chain and the factors that initiated their focus on forecasting and replenishment technology.

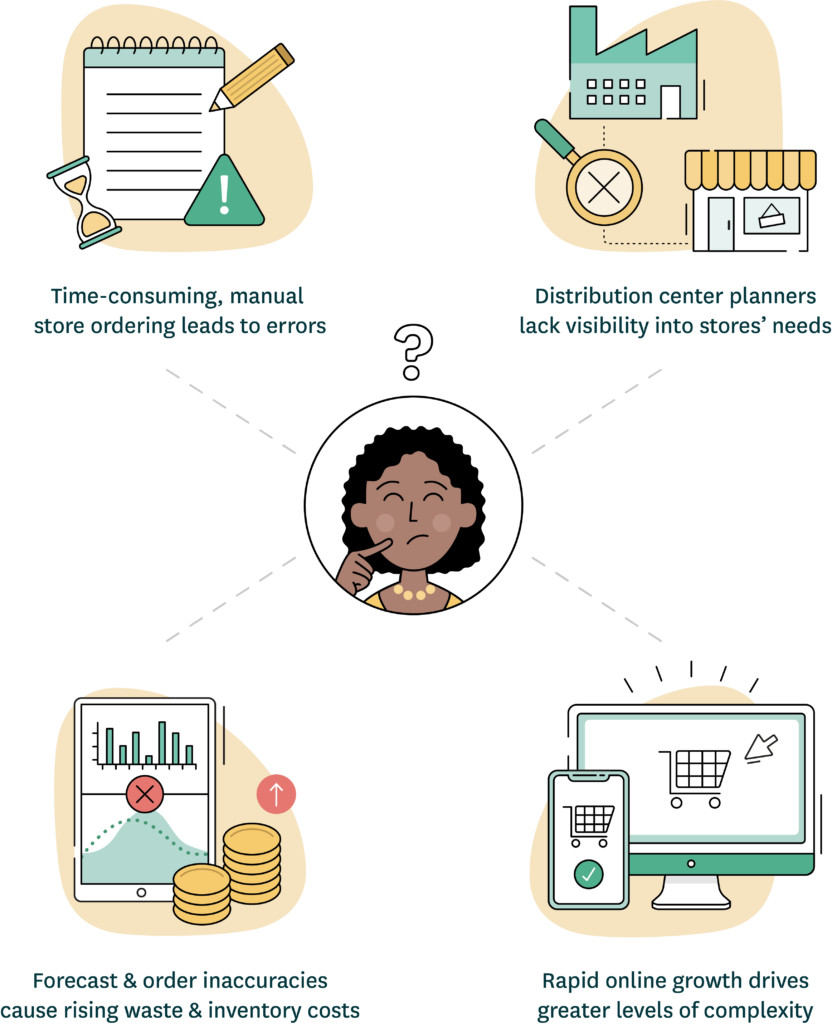

Family Hypermarket currently relies on store department managers to place replenishment orders that keep shelves filled. However, due to the volume of products being reviewed, these replenishment orders are frequently subject to human error. While replenishment of their distribution centers (DCs) is more automated, it is still far from advanced. Their DCs leverage their enterprise resource management system (ERP) to forecast outbound deliveries using simple time-series algorithms, such as exponential smoothing. Family Hypermarkets’ demand planners then manually adjust the resulting forecasts to accommodate for things like upcoming promotions or local events.

Family Hypermarket’s ERP sends order prompts to supply chain planners. However, these orders frequently need manual adjustment because the ERP system can’t automatically accommodate suppliers’ minimum order requirements or the need to fill trucks or containers. Store replenishment and DC replenishment are also disconnected, leaving demand planners at the DCs a lack of visibility into when and in what quantities stores will need inventory to stock up for seasons and promotions.

2.2 Identify Challenge Areas and Improvement Needs

Family Hypermarket’s new SVP of Supply Chain, Sue, has recently joined the company after spending the last few years with another retailer that invested in more modern supply chain management. Although Family Hypermarket’s low-price strategy has been successful and the company is growing, Sue is convinced that Family Hypermarket needs to follow in the footsteps of other leading retailers who have implemented solutions such as:

Automated demand forecasting at the SKU-store/channel-day level that responds to recurring demand patterns such as seasonality and weekday-driven variation in sales, the impacts of business decisions such as promotions and assortment changes, and external demand influences such as weather.

Automated store replenishment that can be managed by a central team of experts rather than store associates, requires little manual intervention, optimizes safety stocks, and considers replenishment schedules and shelf presentation needs.

Allocation optimization that leverages attribute-based forecasting for new or seasonal products to improve accuracy, drive efficient initial allocations and ramp-downs, minimize residual stock, and enable efficient assortment changes.

Integrated supply chain planning where stores’ projected inventory requirements and forecasted online sales drive automated DC replenishment, creating a connected supply chain with a more efficient flow of goods and end-to-end visibility into inventory and resource requirements across the supply chain.

End-to-end demand and supply visibility across the supply chain, which enables proactive management of scarce inventory and capacity bottlenecks, the use of a single stock pool to serve both store and online demand, efficient use of clearance markdowns, and shared visibility and collaborative planning with upstream suppliers.

Improvement in these areas would reduce Family Hypermarket’s operating expenses and free up working capital.

To better understand the potential impacts on their value drivers and the expected return on investment, Sue works to create a detailed business case for investment in modern supply chain solutions to present to the company’s board for approval.

2.3 Develop Realistic Improvement Goals

Based on her experience, market research, and initial discussions with potential vendors, Sue has identified the following improvements that she believes Family Hypermarket can realistically attain through smart investment in better forecasting and replenishment:

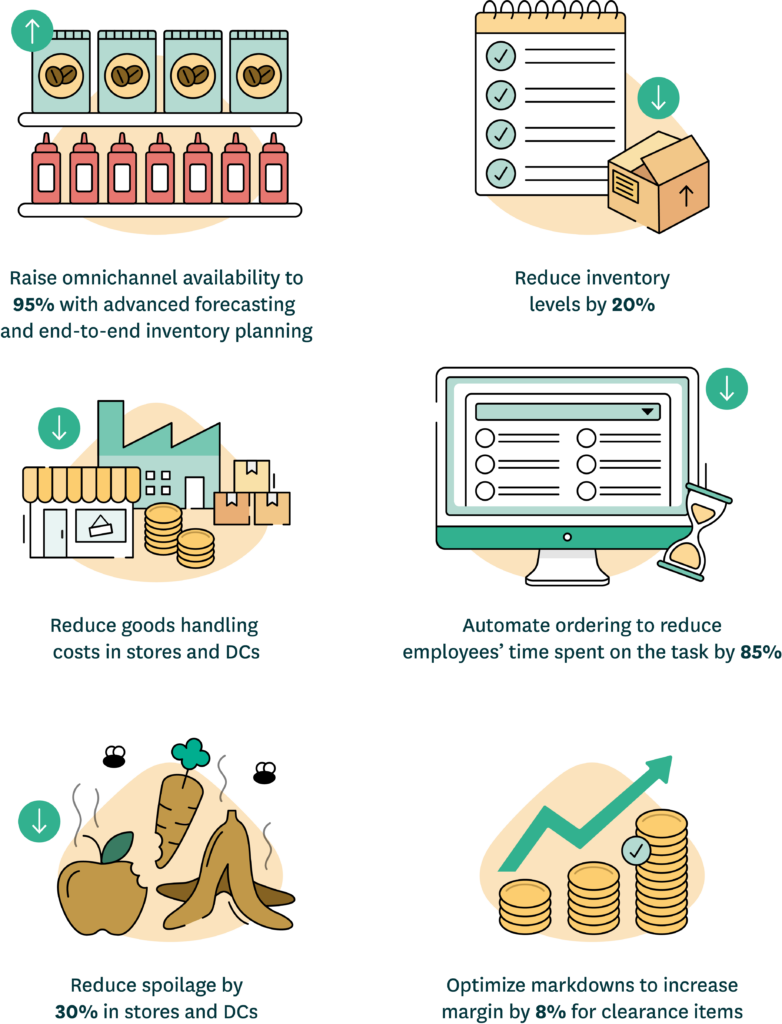

Improve omnichannel availability with advanced demand forecasting and end-to-end inventory management

One of Sue’s primary goals is to increase availability for all of Family Hypermarket’s channels through a supply chain planning solution with demand forecasting capabilities advanced enough to fuel end-to-end inventory optimization. Currently, they experience issues with unnecessary overstocks and out-of-stocks due to their disconnected supply chain processes.

Planners in the DCs need more insights to create granular, day-SKU-channel-level forecasts. These forecasts would feed into automated store replenishment, while inventory requirements for online demand would feed into DC inventory requirements and projected orders to suppliers.

An advanced demand forecasting solution will enable Family Hypermarket to consider hundreds of demand-influencing factors and their impacts with a high level of precision and automation across all locations and sales channels. As a result, planners can support a wide range of short- and long-term planning activities, from replenishment planning to capacity management.

Sue’s goal for a solution implementation is to drive Family Hypermarket’s omnichannel availability up from 92% to 95%.

Reduce inventory levels for improved turns

Along with availability improvements, Sue seeks to reduce Family Hypermarket’s overall inventory levels and drive better inventory turns. Improvements in store ordering accuracy and effectiveness from an advanced forecasting and replenishment solution will enable Family Hypermarket to confidently provide the right products to their customers at the right time. This increases sales through better availability in-store and online and reduces the need to tie up money and storage space on back stock. It also impacts other parts of the supply chain, such as handling, storage, and wastage costs.

Family Hypermarket’s inventory cost for stores and DCs is currently $104 million. Sue is targeting a 20% reduction in inventory, as well as an uplift in inventory turns as a result of optimization.

Reduce waste in stores and DCs

Managing fresh items requires accurate, granular demand forecasting at the store-product-day level. Sue knows that the ability to capture impact factors like seasons, holidays, local events, pricing, promotions, and cannibalization is the key to fresh forecasting and the ability to balance high availability with a low risk of waste.

Sue also wants to enable Family Hypermarket’s safety stocks to account for weekday variations in expected sales volumes. She knows that safety stock levels that guarantee availability on Saturday could mean waste on Monday if not adjusted properly. A good retail planning system performs this kind of dynamic safety stock optimization automatically, keeping waste and availability in balance and driving the highest profits possible.

Spoilage in Family Hypermarket’s fresh categories accounts for approximately $75 million annually, and availability averages 90%. Sue is confident that they can reduce spoilage by 30% while maintaining or improving shelf availability.

Reduce associates’ time spent placing orders in stores

Large-format retailers like Family Hypermarket have tens of thousands of SKUs to manage. Sue is becoming painfully aware that they can’t achieve accurate item-level control through manual store ordering. Decentralized replenishment creates visibility gaps between stores and planners, requiring an inordinate amount of guesswork when manually reviewing things like past promotions to estimate upcoming needs.

Currently, store associates spend more than 300,000 hours annually in Family Hypermarket’s 100 stores manually creating replenishment orders. Sue knows that reducing manual ordering time will translate into better customer service, lower stress levels for existing employees, and less pressure to hire additional employees—an important benefit given how difficult it can be to recruit talented store staff.

Sue’s goal is to use a solution that will centralize replenishment processes to a core team. While store employees will still need to put in some effort to ensure inventory balances are correct, Sue estimates that Family Hypermarket will be able to cut in-store hours on these tasks by 85%.

The automation of demand forecasting and DC replenishment will free up a considerable amount of time for Family Hypermarket’s central planning team. They can spend that time focused on overseeing store replenishment and engaging in collaborative planning with key suppliers. Therefore, Sue is not equating time savings with a reduction in headcount.

Reduce goods handling costs in stores and DCs

A large portion of Family Hypermarket’s operational costs is tied to goods handling, which is typical in retail. Sue estimates they can reduce their current annual cost of $150 million by optimizing the quantities of goods ordered to DCs, leveling goods flows across their supply chain, and consolidating store replenishment according to available space. Automated ordering and replenishment can also be optimized for fresh categories, which often peak later in the week in preparation for consumers’ weekend shopping.

Smoothing the inbound goods flow to stores will help level Family Hypermarket’s workloads, increase their cost-effectiveness, and significantly reduce capacity issues without hampering on-shelf availability. Beyond reducing store handling costs, optimization will also reduce DC picking costs by further decreasing the number of store order lines. In addition, levelling goods flows will simplify Family Hypermarket’s replenishment planning for promotions and major holidays.

Improve margins on markdown products

Sue has determined that Family Hypermarket is losing over $107 million per year in margin due to clearance markdowns. She wants to automate markdown management and create a proactive approach that better balances inventory by clearing out discontinued or outdated products to make room for new products coming in.

Optimization in this area would ensure that the right products are marked down at the right time and the right discount to effectively clear out that unwanted stock while protecting margins and gaining as much revenue from clearance inventory as possible. Further, an automated approach would reduce the amount of time and effort associates put into juggling the movement of old products and new ones. While Sue does not currently have an estimation of how much time store employees spend on this task, she anticipates a substantial reduction in hours and stress for those associates.

Using industry benchmarks, Sue estimates markdown optimization could provide an 8% increase in Family Hypermarket’s margin for markdown products.

She has set specific and measurable goals for both the vendor and her internal implementation team to ensure that everyone understands what they need to deliver when the new technology is introduced.

3. Family Hypermarket’s Business Case for Investing in Supply Chain Technology

With the help of Steve, a business controller from the CFO’s team, Sue’s next step is to translate these expected benefits into financial impacts. She knows some benefits will be hard to quantify, so she also creates a list of intangible, or so-called “soft” benefits.

3.1 The Financial Benefits of Improved Forecasting and Replenishment

1. Improved on-shelf availability that drives additional sales and profit

Family Hypermarket’s average availability stands at 92%. Through research and benchmarking, they estimate that even though customers frequently substitute products, 30% of stockouts lead to lost sales.

Using an advanced solution to connect their end-to-end supply chain would yield an estimated availability increase of 3% points. This increase would result in a potential revenue increase of $45 million annually, leading to a profit lift of $13.5 million.

2. Reduced inventory value saves on carrying costs

Family Hypermarket determined their inventory carrying cost to be 12.5% of their $833 million inventory value, totaling $104 million in carrying costs across stores and DCs.

With an assumed inventory reduction of 20%, they are looking at potential annual savings of $21 million in carrying costs and a more than $166 million reduction in capital tied to inventory.

3. Cost savings through reduction in waste

Family Hypermarket determined that waste costs accounted for 1.5% of their revenue, totaling $75 million annually. While fresh items make up a smaller percentage of their range than traditional grocers, this is still a significant issue to be addressed in their evaluation.

Implementing an AI-enabled forecasting solution would give Family Hypermarket a benchmarked improvement of approximately 30% across DCs and stores, resulting in savings of more than $22 million annually for their fresh products.

4. Reduced time spent placing orders in stores

A review of the time store employees spend on manual ordering revealed that across their 100 stores, Family Hypermarket’s department managers spent more than 310,000 hours annually on store ordering alone. That’s the equivalent of approximately 150 full-time employees and costs the business $9 million annually.

While Sue expects manual ordering in stores to be removed entirely, she knows stores will spend time on associated tasks such as inventory counts and that the automation is based on accurate inventory balances. She therefore estimates that centralized, automated replenishment will reduce the time store associates spend on ordering tasks by 85%. Financially, this means a $7.7 million annual savings on hours spent on manual store ordering. However, because Family Hypermarket is growing and continuously hiring more store associates, these savings will be realized in the form of a slower staff increase instead of fewer work hours for existing employees.

5. Reduced goods handling costs in stores and DCs

Family Hypermarket assessed handling costs as 3% of their revenue, or $150 million, across stores and DCs.

An estimated 3% reduction in DC inbound order lines would reduce DC goods receipt costs by $1.5 million. A 12% reduction in store order lines would reduce DC picking and store goods handling costs by$12 million.

6. More efficient clearance markdowns increase profits and reduce costs for products being phased out

Family Hypermarket currently leaves inventory clearance for stores to handle on an individual basis. Based on current practices, the percentage of revenue from markdowns, and their average discount, they have calculated that they are losing more than $107 million in margin each year on the use of discounts to clear out stock.

After applying estimations from their vendor, Family Hypermarket calculated that optimizing markdowns would result in an average 8% increase in margin for clearance items, giving them a $20 million annual profit increase.

The total financial impact

After completing all her calculations, Sue is confident that implementing a solution that combines more accurate forecasting, inventory optimization, and order optimization will enable Family Hypermarket to achieve their goals. Her confidence in her case comes from the fact that she used an accurate current-state assessment of the business and that she understands not only the ROI of the potential investment, but also the key drivers behind the expected financial outcome.

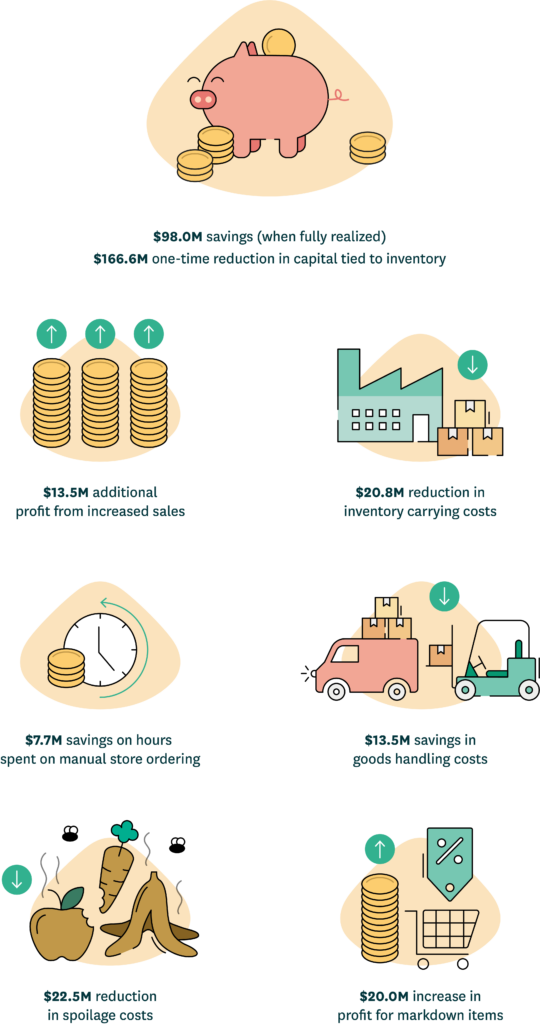

Sue’s business case shows a total potential annual savings of $98 million dollars once the new solution has been rolled out. She also takes into consideration the one-time benefit of $166.6 million savings in capital tied to inventory.

3.2 Considering the “Intangibles” for Retail Technology Investment

The business case calculations that Sue put together show compelling financial benefits for acquiring modern supply chain optimization technology. However, she still needs to consider her list of “soft” benefits—those that are not as quantifiable as the above calculations, but which nonetheless will add considerable value to the Family Hypermarket business. In many ways, these added efficiencies and future-looking benefits can weigh as heavily in the business’s decision as hard numbers.

1. Speed of implementation

Sue is fully aware that the business case outlines a major investment, and that every month that a go-live is delayed could cost Family Hypermarket millions in savings they could have realized earlier. The biggest impact on Sue’s ROI will be determined by how quickly they can complete the implementation, put their new solutions to work, and start reaping the benefits of the investment.

2. Total cost of ownership

Family Hypermarket’s current ERP system has undergone heavy customization over the last several years to sustain the business. Sue will need to evaluate the cost of customization for the solutions she is considering as well.

Flexible systems that can be quickly customized by a core team of expert users are much more cost-effective than those that need a lot of vendor intervention. As Family Hypermarket’s IT department is continuously resource-constrained, Sue will dig deep into what changes and adaptations their supply chain team could take ownership of themselves and to what extent they would need to rely on external assistance.

Sue is also looking forward and assessing the ease and costs of integrating future projects. For example, she knows that Family Hypermarket will replace one of its old DCs with a new one in a couple of years. She is also aware that their click-and-collect offering is gaining momentum and will need considerable integration and planning capabilities soon. Both examples will require speed and agility to execute. Ideally, their new solution will allow them to manage those projects without heavy reliance on the vendor or their internal IT department.

Additionally, Sue is aware that modern software as service (SaaS) solutions help to cut costs by not generating additional server, backup, and maintenance costs.

3. Driving additional value for the business

Finally, Sue is interested in how the investment plan can tie into and drive additional value to the rest of the business. Forecasting and replenishment are core functions for retailers, and the benefits of optimization ripple out to the entire business. For example, automated and more accurate demand forecasts can help with other aspects of planning, such as workforce needs for seasonal and promotional spikes, merchandising and space planning, and supplier collaboration.

Also, from an IT standpoint, it’s always easier to engage with a smaller number of very competent suppliers than a large number of vendors that are hard to keep up with. By consolidating as many solutions as possible with a single vendor, Family Hypermarket can streamline all of their processes into a unified, interconnected environment.

4. The Key Takeaway: Using Real Data Will Drive the Most Reliable Results

As we’ve demonstrated in our hypothetical Family Hypermarket example, building a business case is a necessary exercise when considering any major change or investment. It is especially valuable because it forces you to scrutinize, in detail, your current state and key value drivers and develop realistic goals. However, to get truly reliable numbers on the expected benefits, you must get to a much more granular level than averages.

Industry benchmarks are useful, but simulations that leverage real-life, highly granular data will offer much more valuable insights. It is not possible to accurately determine the ROI for supply chain technology investments until the implementations are fully realized, and the business completes several financial cycles. However, by using researched data and working closely with vendors, you can determine respectable benefit estimations to support your case.

Many technology vendors would be more than happy to help you review your detailed data and show what would change per SKU-channel-day with more accurate forecasting and replenishment. This provides a more accurate understanding of the financial implications these changes would have for your business.

While not all retailers have every type of data or research resource available, collaborating with the vendor to agree on the closest numbers possible is a good idea. Further, when talking to vendors about the assumptions they provide for benefits, those assumptions will ideally be based on experience and not simply be invented numbers.