Demand planning: Key features and best practices for success

Dec 27, 2024 • 16 min

When market volatility and unpredictable consumer behavior are constant threats, even a small window into future demand becomes invaluable.

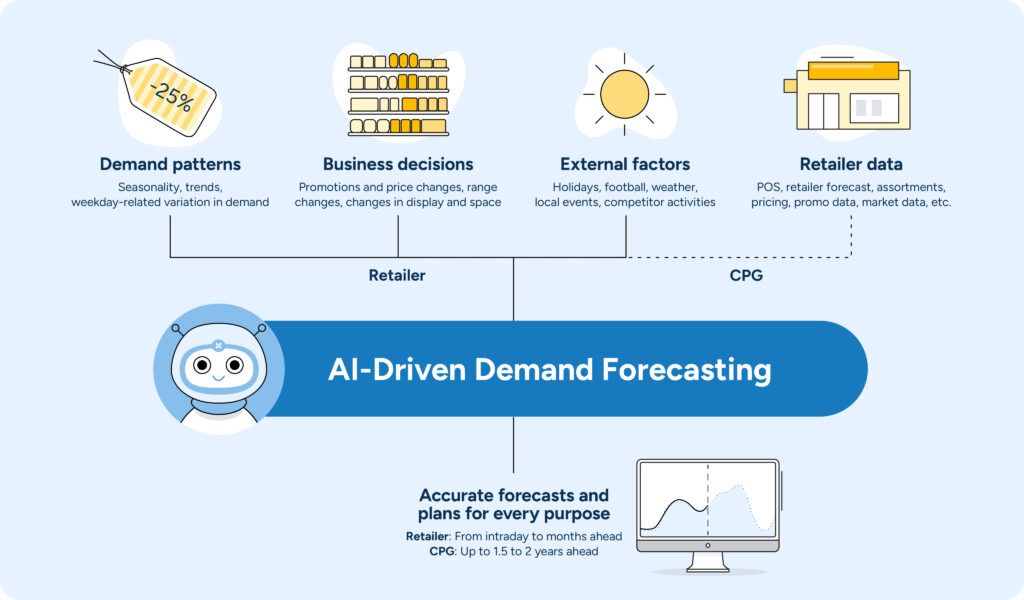

Trying to get as clear a picture as possible of what the future holds is the core of demand planning. And modern technology is getting businesses closer than ever before. Combining artificial intelligence with deep market understanding can anticipate customer needs with unprecedented accuracy. By analyzing everything from weather forecasts and local events to consumer behavior and market trends, organizations can now see what was once obscured by uncertainty.

As consumer preferences shift faster and global supply chains grow more complex, mastering demand planning isn’t just advantageous — it’s critical for business survival and success.

What is demand planning?

Demand planning is anticipating what customers will need in the future. It’s about predicting not just quantities, but timing and location of demand with increasing precision.

This process begins with robust data collection, where historical sales data meets market trends to form a foundation for accurate forecasting. Modern demand planning takes this further by incorporating sophisticated data cleansing techniques to ensure that historical data accurately reflects true demand patterns, not just sales numbers.

Demand planning extends beyond simple data collection into complex analysis, where patterns emerge and insights develop. These insights drive adjustments to demand forecasts, ensuring they reflect not just historical trends but current market realities. Sales forecasting becomes more precise through this iterative process of collection, analysis, and refinement.

Demand planning vs supply planning

While often mentioned in the same breath, demand planning and supply planning serve distinct yet complementary roles in the supply chain ecosystem. Demand planning is focused on predicting what customers will want, while supply planning is the tactical response team, ensuring that necessary resources, materials, and products are available to meet that predicted demand.

For a retailer, these forecasts inform how to allocate inventory across multiple store locations, determine shelf allocations, and prepare staffing for peak periods. For CPGs, it provides insight into production scaling and distribution strategies.

For retailers, a fashion retailer preparing for back-to-school season demonstrates another perspective. Their demand planning team forecasts a 30% increase in denim sales across their store network. The supply planning team then:

- Determines optimal inventory allocation across 500+ store locations.

- Adjusts staffing schedules to handle increased foot traffic.

- Modifies warehouse picking routes to prioritize high-demand items.

For consumer goods companies and manufacturers, a beverage company preparing for summer illustrates the dynamic. Their demand planning team analyzes historical data, weather forecasts, and planned promotional activities to predict a 40% surge in sports drink demand. The supply planning team responds by:

- Securing additional raw materials from suppliers.

- Adjusting production schedules across manufacturing facilities.

- Optimizing distribution routes to ensure timely delivery to retail partners.

This seamless interplay between demand and supply planning creates a robust and responsive supply chain. While demand planning provides the crucial “what” and “when” of customer needs, supply planning executes the “how” of meeting those needs efficiently and cost-effectively.

Why demand planning is critical to supply chain success

The benefits of sophisticated demand planning extend far beyond basic inventory management. Organizations implementing advanced demand planning solutions consistently report dramatic improvements across their operations. Increased sales emerge naturally from better product availability and market alignment. When you can anticipate demand with greater accuracy, you’re better positioned to capture every sales opportunity.

For manufacturers, the impacts are clear: better product availability and market alignment lead to increased sales. When demand can be anticipated with greater accuracy, every sales opportunity can be captured.

Advanced demand planning also significantly improves on-time delivery accuracy, increasing customer satisfaction. Meeting delivery agreements isn’t just good business — it’s essential for survival.

Companies also experience substantial reductions in inventory carrying costs through more precise stock-level management. By holding just the right amount of inventory, they free up working capital without sacrificing product availability.

For retailers, accurate demand planning transforms category performance and profitability. By aligning merchandising decisions with granular demand forecasts, retailers can:

- Optimize inventory levels for each product category.

- Enhance space utilization by allocating shelf space based on predicted demand.

- Reduce waste in fresh categories through precise ordering.

- Balance promotional planning with regular demand to avoid post-promotion inventory gluts.

The impact resonates throughout the retail operation, from improved cash flow through reduced working capital to increased customer satisfaction from better product availability.

The automation inherent in modern demand planning also delivers remarkable savings in manual planning work, allowing teams to focus on strategy instead of routine calculations.

Perhaps most importantly, effective demand planning helps businesses of all types and sizes better manage shelf life and obsolescence, which is particularly crucial for industries dealing with perishable goods or rapidly evolving product lines. The automation inherent in modern demand planning also delivers remarkable savings in manual planning work, allowing teams to focus on strategy instead of routine calculations.

Key components of demand planning

To build an effective demand planning system, organizations must understand and implement several critical components. Each element contributes to the creation of a comprehensive planning process that can adapt to changing market conditions while maintaining accuracy and efficiency. Each essential component works together to create a robust demand planning framework.

Demand management

Demand management orchestrates all aspects of anticipating and meeting customer demand. It integrates many of the other essential components of demand planning — including forecasting, data analysis, and cross-functional collaboration — to ensure that demand predictions effectively guide supply chain actions.

Companies proactively manage demand to align their inventory with market needs, optimize resource allocation, and enhance responsiveness to market changes. This proactive approach minimizes waste and maximizes efficiency.

Demand forecasting

Machine learning (ML) has revolutionized demand forecasting by introducing unprecedented levels of accuracy and automation. These advanced algorithms excel at predicting future demand by processing lots of data from multiple sources — historical sales, market trends, and external factors all feed into the system. What sets modern ML-based forecasting apart is its ability to continuously improve accuracy through learning from new data, creating an ever-more-precise prediction engine.

Demand sensing takes this capability even further by capturing real-time data to detect short-term demand fluctuations. This immediate response to changes in market conditions, promotions, and external events enhances forecast accuracy by integrating near-term signals into the broader prediction model.

Collaborative planning

Effective demand planning requires seamless coordination across departments. Teams across the company must work together to maintain alignment between demand plans and overall business objectives. This cross-functional collaboration facilitates the sharing of crucial insights and enables timely adjustments to forecasts based on real-world feedback.

The collaboration extends beyond internal teams to include key partners. Manufacturers can engage directly with retail customers to better align their forecasts and promotional plans. Retailers can integrate forecasts from suppliers with their own promotional calendars and local events to refine store-level plans. This partnership approach supports joint business planning initiatives and improves forecast accuracy through shared data and insights.

Demand shaping

Modern demand planning empowers organizations to make informed commercial decisions that actively shape demand patterns. Leveraging forecast data enables companies to optimize pricing strategies, plan effective promotions, and launch products with greater success. This proactive approach helps optimize inventory levels and reduce both stockouts and overstock situations.

Success in demand shaping requires careful alignment with business targets and market dynamics. Organizations must ensure their demand plans sync with broader business goals while remaining responsive to market conditions. This alignment enables quick adjustments based on competitive actions, economic indicators, and evolving consumer behavior.

5 steps to better demand planning

Implementing effective demand planning requires a structured approach that builds upon proven methodologies while embracing modern technologies. The following five steps provide a framework for organizations looking to enhance their demand planning capabilities and achieve better business outcomes. Each new step builds on the last, creating a comprehensive approach to demand planning excellence.

1. Increase data quality

The foundation of effective demand planning rests on high-quality, accurate, and comprehensive data. Poor-quality data inevitably leads to inaccurate forecasts, resulting in either costly stockouts or excess inventory. Organizations must maintain rigorous standards for their data, including sales history, inventory levels, and external factors that influence demand.

Regular data cleaning and updating processes ensure the information remains accurate and reliable. This ongoing maintenance might seem tedious, but it’s essential for maintaining forecast accuracy and preventing the cascade of problems that can stem from corrupted or outdated data.

2. Employ more advanced forecasting techniques

Modern markets require forecasting models that can handle multiple variables simultaneously. Today’s advanced techniques consider everything from seasonality and promotions to consumer preferences and local weather events. Machine learning algorithms excel at this complex analysis, improving forecast accuracy while constantly adapting to changing conditions.

Traditional forecasting methods simply can’t capture the complexity of modern markets. More sophisticated approaches, particularly those powered by machine learning, can analyze enormous datasets and identify patterns that humans might miss or would take too long to discover.

3. Integrate POS information

Point-of-sale (POS) data provides invaluable real-time insights into consumer purchasing behavior, with distinct advantages for both retailers and manufacturers.

For retailers, POS data enables sophisticated store-level optimization. Real-time transaction data drives planogram refinement based on local shopping patterns and shelf performance. This granular data enables store-specific assortment planning that reflects neighborhood preferences and supports dynamic pricing adjustments based on sales velocity. Retailers can track promotion effectiveness at the store and SKU level, optimize markdowns based on item-level sell-through rates, and conduct basket analysis for strategic cross-merchandising opportunities.

Manufacturers can leverage retailer POS data to understand product performance through detailed transaction analysis. By examining discount patterns and specific checkout information, manufacturers gain deeper insights into how their products perform in different retail environments.

This granular data supports more accurate forecasting by providing immediate feedback on promotional effectiveness, price sensitivity, and regional variations in consumer behavior. Manufacturers and consumer goods companies can also use this information to optimize their product mix, adjust distribution strategies, and refine their promotional planning based on actual store-level performance.

While collecting and processing this volume of data once seemed daunting, modern AI-powered tools handle it with ease. The integration of machine learning algorithms means organizations can now track product performance, identify trends, and adjust forecasts in real time based on actual sales data. This capability transforms raw POS data into actionable insights that drive better decision-making across the supply chain.

4. Collaborate across the supply chain

Successful demand planning requires active participation from multiple stakeholders across the organization and beyond. Internal departments must maintain open lines of communication and work closely together, while external partners like suppliers and distributors need to be integrated into the planning process.

The key to effective collaboration lies in alignment around common goals. When all parties understand and work toward shared objectives, the entire supply chain operates more efficiently and responsively.

5. Implement scenario planning

Modern markets require flexible planning systems that can adapt to unexpected changes. Scenario planning enables organizations to test different outcomes and strategies using real-time data, helping them prepare for various potential disruptions or opportunities.

Scenario planning embraces the inevitability of unexpected changes. Developing flexible plans that can quickly adapt to disruptions enables organizations to build resilience into their supply chains.

Essential features of demand planning tools

Modern demand planning solutions must incorporate specific features to deliver value in today’s complex business environment. Understanding these essential elements helps organizations select and implement tools that will best serve their needs while enabling continuous improvement in their planning processes.

Automated demand forecasting

Modern demand planning solutions combine automated forecasting with exception-based workflows to handle various business scenarios. From new product introductions to seasonal variations, these systems help manage the complexity of modern demand patterns.

The benefits manifest in multiple ways: increased forecast accuracy through reduced human error, fewer required manual adjustments, and significant time savings in forecasting processes. While challenges exist — such as maintaining data quality and integrating various data sources — robust solutions overcome these through data validation processes and standardized formats.

Granular and aggregate forecasting

Effective demand planning requires both detailed and big-picture views. From ultra-granular SKU/location/day forecasts to aggregate 24-month horizons, modern tools provide the flexibility to support various planning needs. This multi-level approach enables better inventory management and enhanced long-term planning while maintaining consistency across different time horizons.

The key lies in balancing granularity with usability. While detailed forecasts provide precision, they must remain manageable and actionable. Modern systems achieve this through smart aggregation techniques and customizable views that simplify data presentation without sacrificing accuracy.

Channel-specific forecasting

Today’s complex market environment demands channel-specific forecasting capabilities. This granular approach enables better collaboration with key accounts, particularly around promotions, and improves service levels across different customer segments and sales channels.

Reflecting changes in sales channels’ demand more accurately allows organizations to better estimate the impact of promotions, seasons, and other factors at the channel level. This precision leads to enhanced customer collaboration and improved service levels across all channels.

Promotion forecasting and optimization

Modern demand planning solutions must excel at forecasting promotional impacts across the supply chain. This capability combines granular historical data analysis with machine learning to accurately predict promotional uplift at the store, channel, and SKU level.

The system analyzes multiple promotion attributes simultaneously — including promotion type, price changes, advertising strategy, and display placement — to generate accurate forecasts. This comprehensive approach enables organizations to understand both primary effects (increased demand for promoted items) and secondary impacts like cannibalization of similar products.

Benefits emerge through improved promotional execution and resource utilization. Organizations achieve higher forecast accuracy for promoted items, better inventory optimization, and reduced waste from overstock situations. Advanced systems can automate the calculation of initial stock requirements and subsequent replenishment orders, even managing the promotion ramp-down period.

Machine learning engine

Machine learning has revolutionized demand planning by introducing unprecedented levels of accuracy and automation. These advanced algorithms excel at processing vast amounts of data from multiple sources — historical sales, market trends, merchandising decisions, and external factors — to predict future demand patterns. What sets modern ML-based forecasting apart is the ability to continuously improve through learning via new data, creating an ever-more-precise prediction engine.

Implementing ML systems presents challenges — particularly around data quality and output interpretation — but the benefits far outweigh the difficulties. Businesses achieve higher forecast accuracy and more responsive operations through this sophisticated combination of long-term prediction and real-time demand sensing.

Real-time plan adjustments

Modern demand planning tools must enable flexible viewing and adjustment of plans in real time across multiple dimensions. Whether analyzing by customer segment, location type, or time period, planners need the ability to make quick, informed adjustments based on the latest data.

This capability increases planning agility and improves responsiveness to market changes. While maintaining data accuracy and system performance in real-time presents challenges, robust infrastructure and performance optimization techniques help overcome these hurdles.

The role of AI in the future of demand planning

The integration of AI into demand planning represents a fundamental transformation in how organizations approach supply chain management. This evolution isn’t just about keeping pace with technology – it’s essential for maintaining competitiveness in increasingly volatile markets.

Enhanced forecast accuracy

AI, particularly through machine learning algorithms, has revolutionized demand forecasting by handling vast datasets that exceed human analytical capabilities. These systems identify subtle patterns and trends that traditional methods might miss, incorporating everything from historical sales data to seasonal trends and promotional activities.

The result is more comprehensive and realistic forecasts that reflect real-world complexities. By considering multiple demand drivers simultaneously – from seasonality to promotions and external events – AI-powered systems deliver unprecedented accuracy in demand prediction.

Demand sensing and shaping

Modern AI systems excel at sensing real-time demand changes and adjusting strategies accordingly. By monitoring data from various sources, including POS systems and market trends, these systems detect shifts in consumer behavior as they happen. This capability extends to social media analysis, enabling organizations to identify emerging trends and potential market shifts before they fully materialize.

This real-time insight enables swift adjustments in inventory levels, targeted promotions, and marketing strategies, enhancing organizational agility in meeting consumer demands.

Scenario simulation

The combination of predictive and generative AI in supply chain enables sophisticated scenario simulation capabilities. Organizations can now create detailed simulations of potential disruptions, from supplier failures to transportation delays, and develop robust contingency plans.

This proactive approach enhances supply chain resilience and continuity. Consumer goods companies, wholesalers, and retailers alike can swiftly respond to market shifts and strengthen partner relationships despite challenges. The ability to test different strategies in a simulated environment helps organizations choose the most effective approaches to various scenarios.

How these companies accomplished better demand planning with RELEX

Organizations across different industries in CPG, retail, and wholesale have leveraged modern demand planning capabilities to achieve measurable improvements in their operations. From increased forecast accuracy to reduced inventory costs, these examples illustrate the practical impact of sophisticated demand planning tools.

Finsbury Food Group

- Reduced net working capital by £1.6 million through smarter procurement

- Doubled planning team productivity with minimal staff additions

- Improved service levels by 5% year-over-year

One of the UK’s leading specialty bakery manufacturers, Finsbury Food Group, faced a complex challenge: how to optimize a diverse network of factories with varying levels of automation and time-sensitive processes. Despite implementing a common ERP platform in 2018, Finsbury Food Group still relied heavily on legacy planning tools and spreadsheets, limiting their ability to scale and integrate future acquisitions effectively.

The company’s transformation journey began during an unprecedented time – the onset of the global pandemic. Despite facing significant disruptions in consumer behavior and shortages in staff and materials, Finsbury pressed forward with implementing RELEX’s unified planning solution. They took a methodical approach, running their new and old forecasting systems in parallel to ensure a smooth transition and proper staff training.

The results proved transformative. The new AI-driven demand forecasting and production scheduling optimization enabled Finsbury to make proactive planning decisions and identify necessary adjustments in labor and resource capacity.

Planning teams now work twice as efficiently, handling double their previous workload with the addition of just one team member. Real-time insights have improved collaboration between demand and supply planners, while enhanced scenario planning capabilities help them capitalize on available capacity and optimize working capital deployment.

Norgesmøllene

- Achieved precise 18-month weekly forecasts across all business areas

- Significantly improved demand visibility through automated algorithm selection

- Streamlined S&OP process with enhanced cross-departmental collaboration

For Norgesmøllene, a Norwegian food producer with roots dating back to 1866, the challenge was clear: how to maintain their heritage of quality while meeting modern market demands. In 2023, they embarked on an ambitious upgrade to their entire supply chain planning infrastructure, choosing RELEX for its robust capabilities and industry expertise.

The transformation centered on implementing advanced demand planning capabilities that generated precise 18-month weekly forecasts across all business areas. The system’s ability to automatically select optimal forecasting algorithms significantly improved demand visibility and forecast accuracy.

Beyond the numbers, the new system facilitated enhanced cross-departmental discussions and streamlined their S&OP process. For a company with over 150 years of history, this technological leap forward ensures they’ll remain competitive for generations to come.

Blendwell Food Group

- Improved forecast accuracy and customer service levels by 5-10%

- Achieved measurable waste reduction within three months

- Enabled real-time forecast adjustments and integrated supply planning

Blendwell Food Group’s story illustrates the power of modernizing planning processes. As a Dutch producer of dried fruits and nuts, they struggled with slow, labor-intensive planning processes that relied heavily on manual spreadsheets. In February 2022, they partnered with Supply Chain Company and chose RELEX to revolutionize their planning processes.

Within just three months, the results proved remarkable: forecast accuracy and customer service levels improved by 5-10%, and waste reduction trends became immediately apparent. The implementation enabled real-time forecast adjustments, integrated supply plans, and enhanced S&OP processes, reducing overproduction risks and improving workflow efficiency.

Perhaps most importantly, the new system gave Blendwell unprecedented visibility across the supply chain, enabling better assessment of opportunities and risks while enhancing proactive planning capabilities.

These success stories demonstrate how effective demand planning drives remarkable improvements across organizations: forecast accuracy reaching up to 99%, stockout reductions of up to 85%, and inventory reductions of up to 30%. These aren’t just numbers – they represent real business transformation through the power of modern demand planning.

From insight to action

The evolution of demand planning from basic forecasting to strategic foresight represents one of the most significant advances in modern supply chain management. Today’s businesses no longer need to react to market changes after the fact — they can anticipate and respond to shifts before they become problems.

This proactive capability is transforming how organizations operate in this era of change and complexity. The future belongs to businesses that can not only predict demand but actively shape it, creating more resilient and responsive supply chains that deliver value to both businesses and their customers.

Demand planning FAQ

What's the difference between demand planning and demand forecasting?

Demand forecasting is the analytical process of predicting future customer demand using statistical methods, while demand planning is the broader strategic process that uses these forecasts to make business decisions about inventory, production, and distribution across the organization. Forecasting provides the numerical predictions, while planning translates these predictions into actionable business strategies.

What's the difference between demand planning and demand management?

Demand planning is the process of forecasting future customer demand and creating strategic plans for inventory, production, and distribution based on these forecasts. Demand management is a broader concept that encompasses not only planning for demand but also actively influencing and shaping it through pricing strategies, promotions, product design, and customer relationship activities.

While demand planning focuses primarily on anticipating and preparing for demand, demand management includes strategies to optimize and modify demand patterns to align with business objectives and capabilities.

What are the key components of an effective demand planning process?

Effective demand planning combines advanced technology with collaboration and continuous improvement. Key components include:

- AI-driven forecasting leveraging historical data and demand signals for accuracy

- Demand sensing to respond quickly to real-time changes in demand

- Collaborative planning with input from sales, marketing, and supply chain teams

- Granular visibility into demand drivers and inventory levels

- Automation to streamline processes and reduce manual effort

- Scenario planning to prepare for market uncertainties

- Integration across supply chain processes to align with financial and operational goals

The process should be cyclical, with clear timelines, responsibilities, and mechanisms to measure and improve forecast accuracy and business alignment.