Boosting efficiency in the FMCG supply chain

Oct 15, 2024 • 8 min

The FMCG (fast-moving consumer goods) supply chain is characterized by the rapid turnover of typically low-cost and high-volume items such as food, beverages, toiletries, and the other consumables that fill our daily routines. In other words, the products that make up our day-to-day activities are the lifeblood that pumps through the FMCG supply chain.

But let’s be real—managing this whirlwind of products is no walk in the park. It takes top-notch inventory management, smooth production planning, and spot-on distribution strategies to make sure supply meets demand, costs stay low, and shelves stay stocked.

What is the FMCG supply chain?

The FMCG supply chain refers to the network and processes involved in producing, distributing, and selling high-volume, low-cost products that consumers frequently purchase.

If the FMCG supply chain could be summed up in two words, it would be “speed” and “efficiency.” Without both, most consumer goods companies would struggle to meet the increasingly high demand for their products.

Unlike supply chains for bigger, more durable goods, the FMCG supply chain deals with perishable items that need precise inventory management and quick restocking. FMCG companies have to constantly tweak their supply chains to balance supply and demand, cut down on waste, and keep products available.

With demand for FMCG products being so unpredictable, companies need to stay agile and responsive. Getting the right product to the right place at the right time is crucial. That’s where mathematical optimization and reliable forecasting come in handy.

Competition throughout the FMCG supply chain

On top of being highly volatile, the FMCG sector is highly competitive, with companies vying for market share against both established brands and private labels. These private labels are often manufactured by a third party and sold by retailers under their own name.

Although different retail channels like Direct-to-Consumer (DTC) or online channels like Amazon allow manufacturers to get their products to consumers faster, they also significantly increase complexity that needs to be constantly monitored, assessed, and catered toward.

This intense competition necessitates that FMCG companies focus not only on the efficiency of their supply chains but also on innovation and differentiation. It’s not just about what’s in the product but also how it’s packaged.

To stay ahead, companies need to keep up with changing consumer preferences and market trends. Being able to quickly respond to demand shifts, like those from promotions or seasonal changes, can give them a real edge.

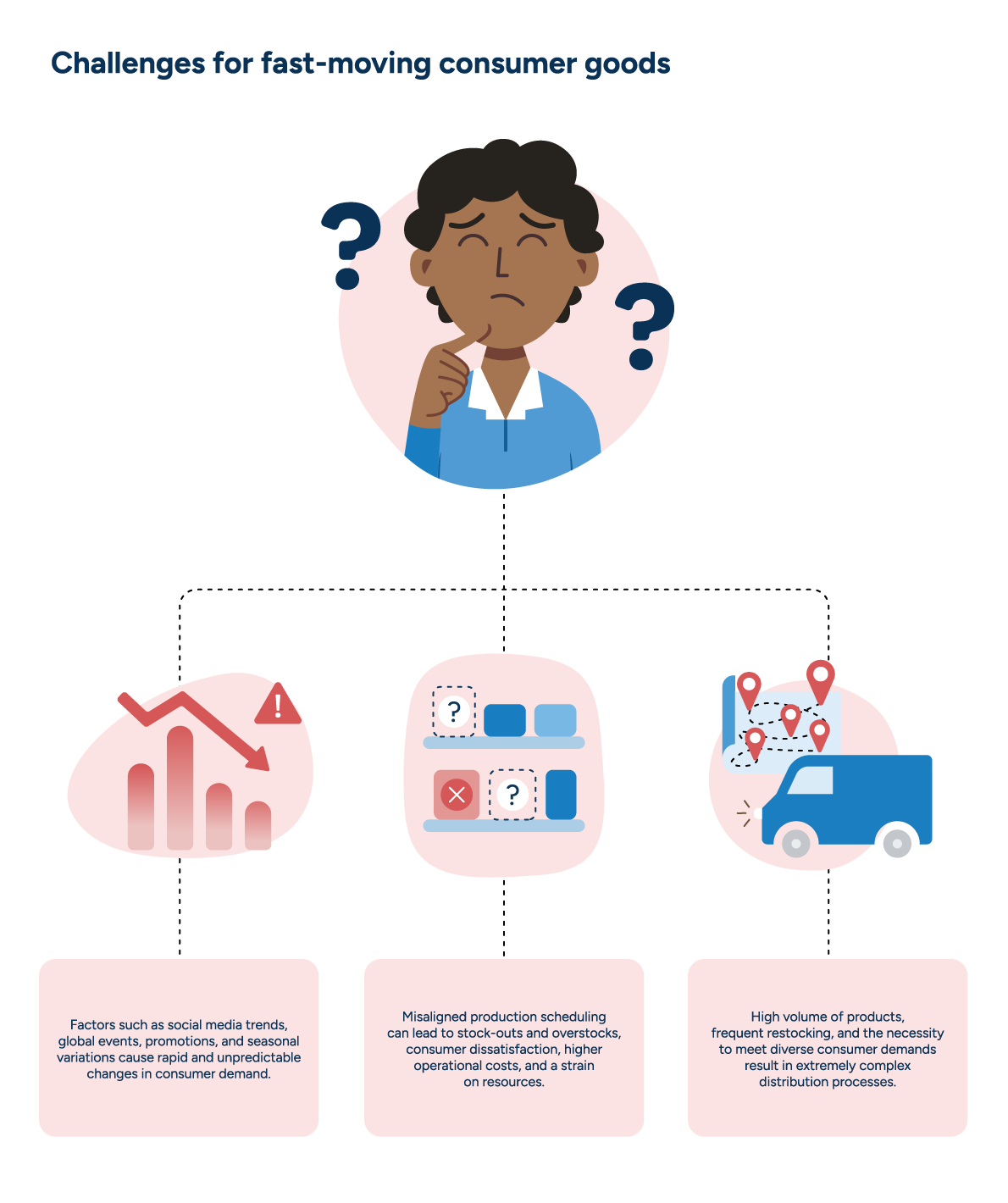

FMCG supply chain challenges

The FMCG sector is fraught with unique challenges that require agile and efficient supply chain management. Here are three of the most pressing supply chain challenges facing FMCG companies today:

1. Demand volatility

Demand volatility refers to the rapid and unpredictable changes in consumer demand for products.

Factors influencing demand volatility include:

- Social media trends

- Global events

- Competitive actions

- Promotional activity

- Weather

- Seasonal variations

Managing this volatility is crucial for maintaining supply chain efficiency and accuracy, as it impacts forecasting, inventory management, and the ability to respond quickly to market changes.

One big issue with demand volatility is the bullwhip effect. As demand signals move from the point of sale (POS) back to the manufacturers, they become more distorted. This effect can lead to overproduction or underproduction, causing inefficiencies, higher costs, and a lot of last-minute scrambling. Plus, brand switching due to inflation and price sensitivity makes demand forecasting and inventory management even trickier.

2. Complexity in capacity balancing

Capacity balancing involves ensuring that different stages of the production process are well-aligned and balanced to avoid bottlenecks and slack capacities. This is especially tough in the FMCG supply chain because of seasonal changes and unexpected production issues. Plus, factors like volatile input costs, concentration risks, and geopolitics add extra layers of complexity and risk.

Volatility in input costs:

- Fluctuating prices of raw materials

- Increased labor costs

- Climate change impacting supply

Concentration risks:

- Over-reliance on a limited number of suppliers or regions

- Increased vulnerability to disruptions in specific areas

- Limited optionality in transportation

Role of geopolitics:

- Trade restrictions and tariffs

- Political instability affecting supply routes

- Regulatory changes impacting sourcing, production, and distribution

Production scheduling is also crucial because of the high number of SKUs and the need for frequent changeovers on production lines. Efficient planning has to take all these factors into account to keep production running smoothly, minimize downtime, and boost productivity.

3. Distribution complexity

Distribution complexity encompasses the intricate challenges in managing goods’ movement from production to the end consumer. This includes:

- Optimizing transportation routes

- Managing inventory levels across multiple locations

- Ensuring timely and accurate deliveries

- Balancing costs with service levels

The complexity arises from the need to handle a high volume of products, frequent restocking, and the necessity of meeting diverse consumer demands.

Efficient distribution management is key to making sure products are available when and where consumers need them. This requires advanced logistics planning, real-time tracking, and coordination across various stakeholders in the FMCG supply chain.

Strategies for optimizing the FMCG supply chain

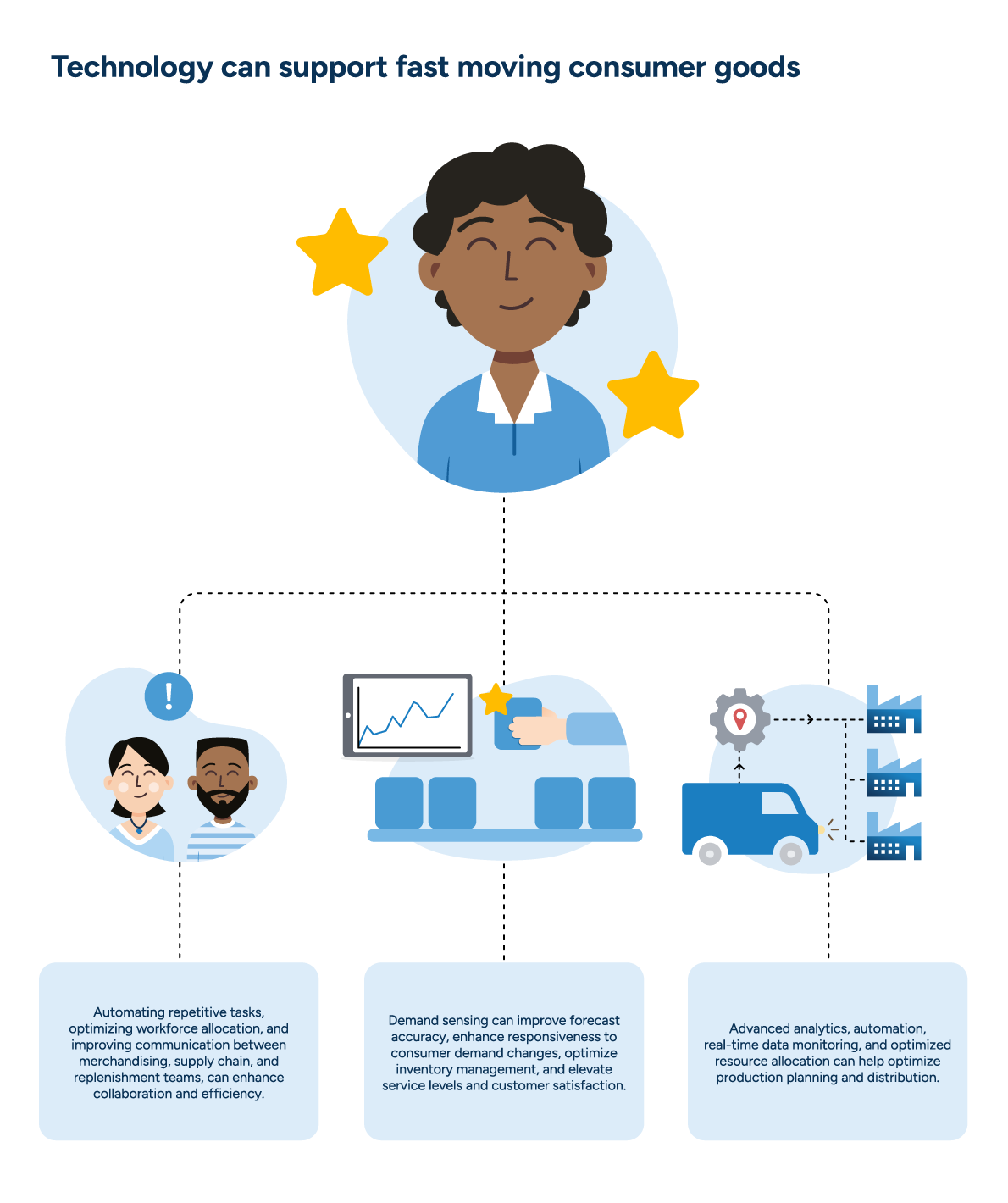

Collaboration with retailers

FMCG companies can use tech solutions to work better with retailers by integrating unified platforms that streamline planning, enhance data sharing, and improve visibility across the supply chain.

These tools help with accurate demand forecasting, balanced replenishment, and efficient inventory management, cutting down on waste and boosting in-stock rates. They also make collaboration and operations smoother by automating repetitive tasks, optimizing workforce allocation, and ensuring seamless communication between merchandising, supply chain, and replenishment teams.

The benefits of these collaborative technology solutions for FMCG companies include:

- Accurate demand forecasting reduces stockouts and spoilage.

- Balanced replenishment ensures optimal inventory levels.

- Efficient inventory management minimizes waste and increases in-stock rates.

- Automation of repetitive tasks boosts productivity and reduces labor costs.

- Optimized workforce allocation enhances operational efficiency.

- Seamless communication between teams improves collaboration and decision-making.

- Enhanced data sharing and visibility across the supply chain.

Demand sensing

Fast-moving consumer goods companies can use demand forecasting and sensing to improve supply chain management by leveraging real-time data to create more accurate forecasts and respond swiftly to changes in consumer demand. This approach helps reduce stockouts and excess inventory, optimize replenishment processes, and enhance overall supply chain visibility down to retail customers.

By factoring in seasonal changes, promotions, and consumer preferences, and using retail data to sense changes in end-consumer demand, FMCG companies can better align production, distribution, and procurement with actual market demand, improving efficiency and reducing waste. This is especially useful since companies often rely on retailer reorders for forecasting, which might not reflect real-time consumer demand.

Demand sensing also enables proactive scenario planning, allowing companies to test different strategies and anticipate potential challenges, making more informed decisions.

Implementing demand sensing in FMCG companies offers several significant benefits:

- Elevates service levels and minimizes lost sales.

- Improves inventory turnover by responding to real-time demand signals.

- Enhances demand planning efficiency by incorporating external data like weather and POS data.

- Reduces spoilage and waste through better alignment of supply with actual demand.

- Enables proactive scenario planning for better decision-making.

- Increases sales and availability by modeling promotional impacts such as cannibalization and halo effects.

Optimizing production and distribution

Optimizing production and distribution in the FMCG sector requires a strategic approach that integrates advanced technologies and data-driven insights. By leveraging AI and machine learning, companies can create highly accurate demand forecasts that inform production schedules and distribution plans. This strategy ensures that products are manufactured and delivered in the right quantities, at the right time, and to the right locations, minimizing waste and reducing costs.

Efficient production planning involves sequencing production orders to minimize changeover times and maximize equipment utilization. This system is particularly important for managing allergen control and ensuring compliance with safety standards. On the distribution side, optimizing transportation routes and warehouse operations can significantly enhance delivery speed and reliability, ensuring that products reach consumers quickly and in optimal condition.

Real-time monitoring and quick replanning capabilities are essential to address any disruptions in the supply chain, such as equipment failures or sudden changes in demand. By continuously aligning production and distribution activities with current market conditions, FMCG companies can maintain high service levels, reduce operational costs, and stay competitive in a fast-paced market.

By optimizing production and distribution processes, FMCG companies can achieve several key benefits:

- Enhances service levels and customer satisfaction through timely deliveries.

- Reduces operational costs by optimizing production schedules and transportation routes.

- Improves equipment utilization and minimizes downtime with efficient production sequencing.

- Ensures compliance with safety standards and allergen control through strategic planning.

- Increases flexibility and responsiveness to market changes with real-time monitoring and quick replanning.

- Maintains a competitive edge by continuously aligning operations with current market conditions.

Strategies in action: Optimizing Vita Coco’s global operations

The company Vita Coco exemplifies how leveraging advanced supply chain strategies can alleviate the key challenges faced by FMCG companies. By implementing FMCG supply chain optimization solutions, Vita Coco has effectively handled demand volatility, capacity balancing, and distribution complexity.

Addressing demand volatility

Vita Coco’s use of digital twin modeling and machine learning capabilities allows for precise demand forecasting and scenario planning. This approach mitigates the bullwhip effect and ensures that production aligns closely with actual market demand, reducing the risks of overproduction and underproduction. By simulating various business scenarios, Vita Coco can proactively anticipate changes and adjust their supply chain planning strategies, leading to more accurate and responsive demand management.

Enhancing capacity balancing

RELEX helps Vita Coco manage its complex production processes by modeling every node in the supply chain, including costs, rules, and constraints. This comprehensive modeling considers capacity constraints at each factory and co-packer, optimizing the production flow and minimizing bottlenecks. By integrating shipping costs and import duties into the optimization tool, Vita Coco can balance production and logistics capacities more effectively, enhancing overall efficiency.

Simplifying distribution complexity

Vita Coco’s optimized 18-month supply plan, generated through RELEX, streamlines logistics operations and inventory management. This plan guides production scheduling, packaging material requirements, and staff planning, ensuring that products are available where and when needed. The improved S&OP process, based on a common supply plan, fosters better collaboration and visibility across the supply chain, reducing delays and costs while maximizing service levels and customer satisfaction.

Vita Coco’s strategic use of supply chain optimization tools demonstrates how FMCG companies can overcome the challenges of demand volatility, capacity balancing, and distribution complexity. By leveraging advanced planning and optimization technologies, Vita Coco has achieved significant cost reductions, improved efficiency, and enhanced decision-making capabilities, setting a benchmark for success in the FMCG sector.

Ready to transform your own FMCG supply chain? Discover how advanced supply chain optimization can help you navigate demand volatility, balance production capacities, and simplify distribution complexities.