Tackle food manufacturing supply chain challenges with the right planning solution

Nov 16, 2023 • 7 min

Demand needs versus supply realities. Production constraints versus customer obligations. Long-term planning versus short-term flexibility.

Planners in food processing engage in a perpetual, high-stakes tightrope act as they balance production schedules, business constraints, and material scarcity against ever-changing demand and the looming threat of spoilage. A change in any one variable can send service levels spiraling and profitability plummeting — catastrophic outcomes in an industry operating within razor-thin margins.

Even the most skilled teams of planners find that manual processes, disconnected planning, and a lack of visibility into the end-to-end supply chain hinder their attempts to balance cross-functional production obligations. Without a single plan to unify behind, planners on different teams may find themselves working against each other instead of working together to satisfy customer obligations and maximize business profits.

Planning in food processing doesn’t need to feel like a circus act. The right digital tool will provide organizations with the visibility and collaborative capabilities required to overcome the food manufacturing challenges they face and complete customer orders in the most profitable way.

Balance push and pull production models

Food manufacturers often struggle to balance the need to maintain a steady supply with the obligation to satisfy ever-changing customer demand.

Take a dairy manufacturer. Weekly milk production is unpredictable. If the output for a given week is less than anticipated, the company will struggle to determine what products to produce and which outstanding customer orders to satisfy.

There’s also the opposite problem. Manufacturers are often obligated to take a farm’s entire milk supply regardless of demand and must use the entire volume regardless of demand or risk costly spoilage.

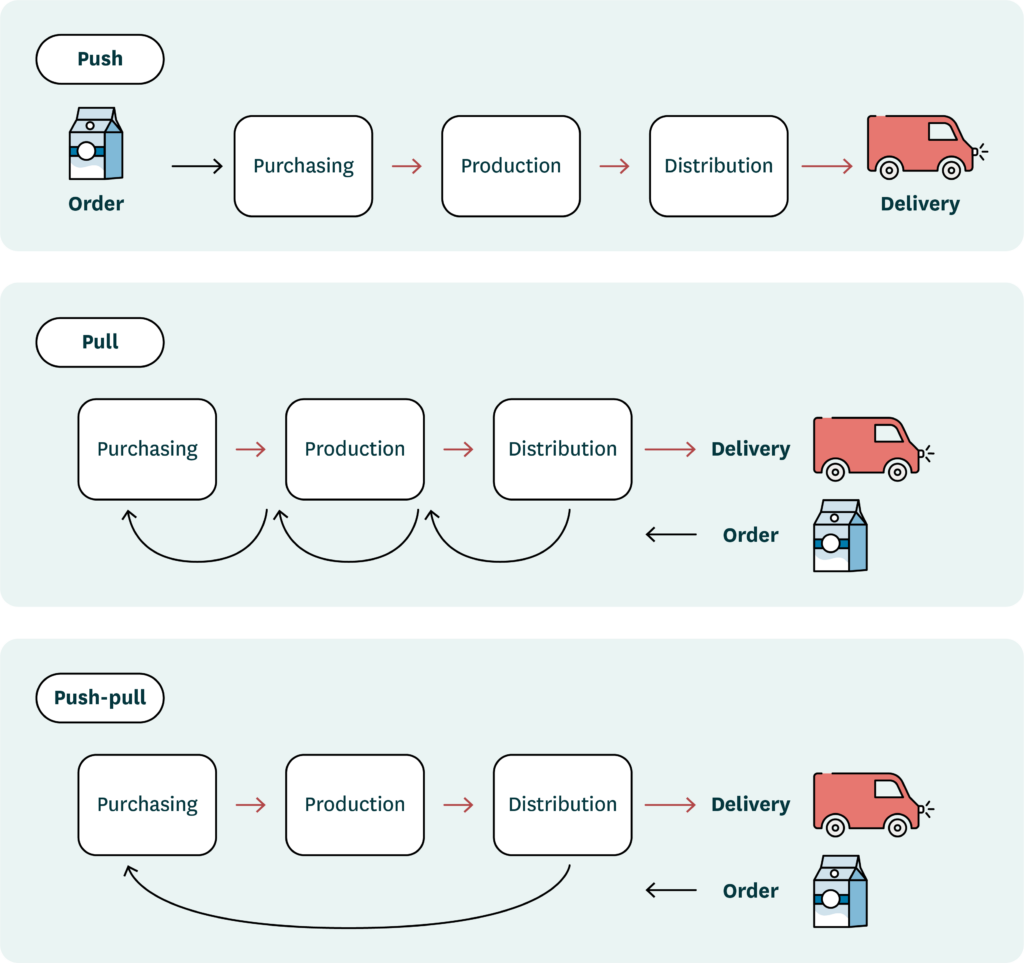

Push, pull, and hybrid production

This example illustrates the tension between the push and pull production models common to food processing. In a push model (also called a “make-to-stock” model), companies produce goods based on demand forecasts. Companies produce items in advance, allowing them to fulfill customer orders immediately. This model works well for frozen items or more shelf-stable products like beverages, but the need to keep product on hand can lead to increased spoilage risks for manufacturers dealing with fresh foods.

The need to keep product on hand can lead to increased spoilage risks for manufacturers dealing with fresh foods.

Pull models (or “make-to-order” models) work from the opposite end of the spectrum. Manufacturers make and order raw materials based on forecasts, as actual customer requests typically come in mere days before the fulfillment deadline. In other words, products are essentially made to order. Forecasts allow manufacturers to buy only as many raw materials as needed, reducing storage costs. However, this model falls short when demand spikes, potentially causing missed orders and strained customer relationships.

Fresh food can’t sit around long in storage, but companies also need staple items ready to go when demand shifts. Most manufacturers use hybrid push-pull models to overcome these issues. Unfortunately, these companies rarely have a system for determining what mix of push and pull methodologies maximizes operational efficiency and profitability.

Profit-optimized push-pull models

A robust planning platform can balance demand forecasts and customer orders, but the best ones go further. Instead of considering outcomes in terms of “push” and “pull” methods, advanced platforms simulate every possible plan to identify the one that is the most profitable or cost-effective. Manufacturers still accomplish their goals through a hybrid push-pull production model, but data determines the optimal way forward, not gut feelings or past practices.

The catch? What’s cost-optimal for a manufacturer isn’t always satisfactory for their customers. Without guidance, optimization software may determine it’s cheaper to ignore one customer’s orders entirely over a given period to satisfy the orders of another trading partner.

This possibility necessitates the ability for manufacturers to add their business constraints and rules into the calculations to ensure the consideration of contractual obligations and production limitations. Fortunately, this comes standard in a comprehensive planning platform like RELEX.

The addition of these business constraints and rules helps food processing manufacturers prioritize production methods based on their business needs and objectives. A fresh food manufacturer can create a plan optimized around their spoilage concerns. Meanwhile, shelf-stable goods manufacturers with better control of their supply can create plans optimized for maximum customer order fulfillment.

READ MORE: Why fresh packaged food manufacturers must prioritize freshness

Convert one material source into multiple products

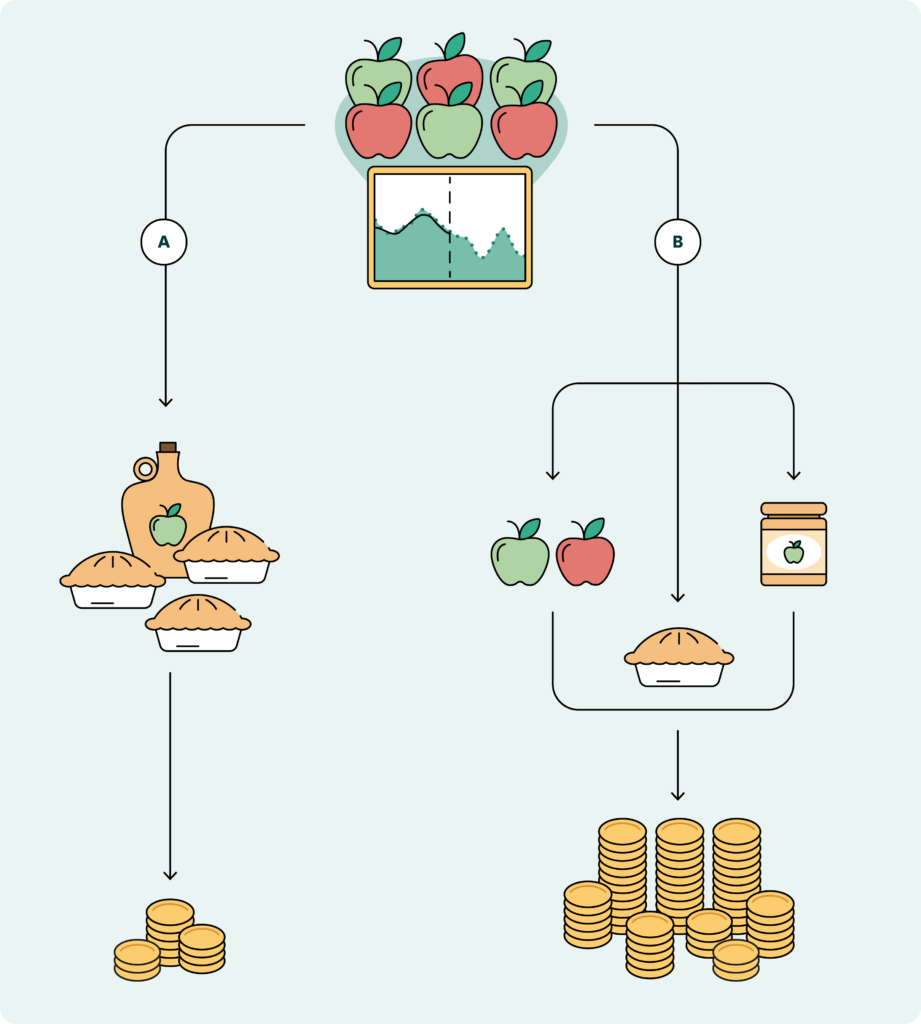

Cost-optimized plans must also factor in the complexity of disaggregation—the act of producing several varying products from a single type of raw material. Consider bushels of apples, from which manufacturers could theoretically produce a range of products, including applesauce, juice, cider, vinegar, and pie.

The difficulty lies in determining which mix of these possible end products fulfills customer orders most profitably. To do this, manufacturers must weigh several variables, including:

- Customer order priority. What products are needed immediately to satisfy the obligations of the most lucrative customer contracts?

- Forecasted demand. What products will be needed soon to meet anticipated demand shifts?

- Production constraints. What’s the most efficient production schedule considering available production lines, downtime for changeover and cleaning, and available labor?

- Material scarcity. When is the next batch of raw materials coming in, and how much volume will it contain?

Even the most skilled planning team would struggle to make the necessary calculations to discover the most cost-optimal plan given these variables. If a team ever managed to determine the optimal product mix manually, the calculations would likely take far too long to act on. This is especially true for the many manufacturers still laboring under manual processes and operating from an untold number of spreadsheets.

The difficulty lies in determining which mix of possible end products fulfills customer orders in the most profitable way.

Planning platforms like RELEX simulate every conceivable scenario, factoring in order obligations, supply realities, and production constraints to determine the most profitable and realistic plan for that period. Production plans are updated with up-to-date data every night, ensuring that the production plan for any week remains optimized despite supply chain changes.

These simulations are especially beneficial in meat manufacturing, where margins are typically low. Say the demand for chicken breasts is far higher than for thighs. Manufacturers must harvest the entire bird to get the needed breast cuts, which leaves too many thighs and insufficient demand for them.

The most advanced planning solutions can suggest the optimal cuts for manufacturers to maximize production of in-demand goods. The platform will also provide alternative uses for the remaining cuts, such as converting them to frozen goods, to increase shelf life and mitigate spoilage risks.

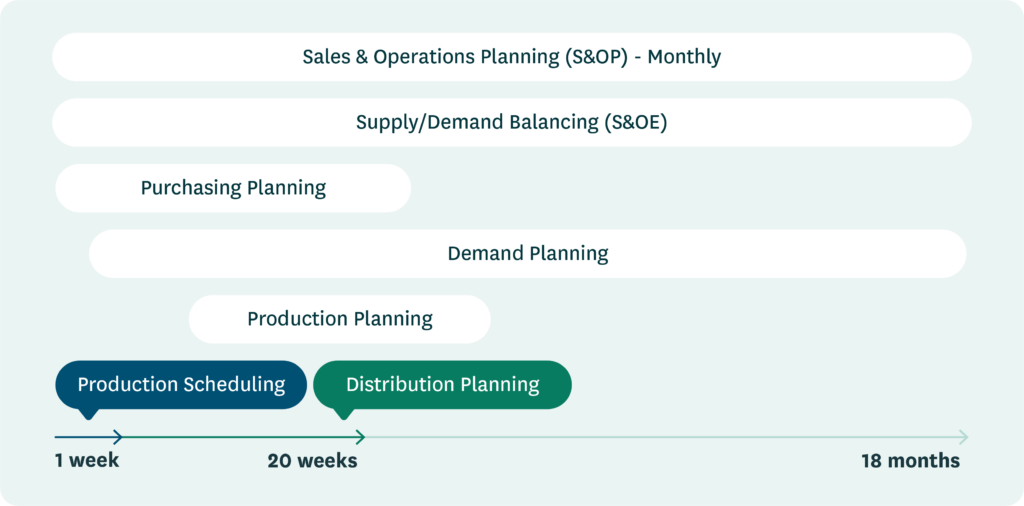

Synchronize planning across teams and time horizons

Sometimes, the biggest challenge is simply getting teams within an organization on the same page. Many food processing manufacturers lack a single source of truth in planning and data analysis. This forces individual demand planning, distribution planning, production planning, and purchasing teams to develop their own systems and processes.

Despite being born out of necessity, these discrete systems only compound planning issues. Essential data is siloed within each team. Without a way to collaborate around up-to-date data in a live setting, teams cannot fully align on broader long-term business planning objectives. Teams operate from separate plans, rendering cost-optimization impossible.

Manufacturers need an advanced planning and scheduling (APS) solution that deconstructs these siloes and synchronizes planning across teams. Enhanced internal collaboration allows sales, operations, and purchasing to unify behind a single plan to maximize efficiency across the production process and identify how even small decisions impact higher level business goals.

A unified planning system allows a manufacturer to create a new forecast immediately visible to all stakeholders. This enables teams to work on many tasks simultaneously instead of completing them sequentially. For instance:

- The sales team could test the feasibility of the forecast’s execution using the planning software’s digital supply chain twin, adjusting the forecast depending on the results.

- The operations team could build labor schedules and allocate resources according to the most up-to-date version of the forecast.

- The purchasing team could identify supplemental or alternative suppliers to maintain a constant flow of raw materials at the most cost-effective rate.

Scheduling plans that play out in weeks can be aligned with broader manufacturing plans executed over the course of months — and with sales and operations planning initiatives that take years.

The benefits of a unified planning system extend beyond horizontal collaboration. Teams can also synchronize planning vertically across time horizons and planning layers. Scheduling plans that play out in weeks can be aligned with broader manufacturing plans executed over the course of months — and with sales and operations planning initiatives that take years.

Adjustments in one planning layer ripple through the others, allowing for manufacturers to retain internal alignment without sacrificing adaptability. This total horizontal and vertical synchronization enables companies to build cost-optimal plans in the short term without losing sight of long-term revenue growth.

READ MORE: Transform consumer goods S&OP with next-level demand shaping

Overcome food manufacturing supply chain challenges with an end-to-end planning solution

True optimization of the food processing supply chain requires a holistic understanding of supply and demand and a way to visualize the flow of goods from source to supermarket. This isn’t a pipe dream. The technology to accomplish this exists currently and works wonders. Unfortunately, many planning solutions only address a sliver of a manufacturer’s substantial needs, causing them to purchase multiple tools that only improve processes in half-measures.

RELEX provides the end-to-end visibility and synchronous planning capabilities needed to thrive in an ever-challenging market. What’s more, we’ve worked alongside fresh food manufacturers, wholesalers, and retailers for years, so we know fresh supply chain planning better than anyone — and we’d like to prove it to you.