Food waste is among the most critical, and controllable, expenses in grocery retail

Every unsold strawberry, expired yogurt, and wilted lettuce leaf represents both lost revenue and wasted resources for grocery retailers. With razor-thin margins throughout the industry, food waste remains one of the largest controllable expenses in the business — costing retailers up to twice as much as retail profit. Transforming this waste into profit creates a powerful opportunity to simultaneously strengthen financial performance and advance sustainability goals, delivering both bottom-line and environmental benefits through the same practical inventory improvements.

AI-driven forecasting, multi-echelon supply chain optimization, and advanced fresh capabilities offer actionable strategies for cutting waste-related costs, reducing spoilage, and optimizing fresh product management. By implementing these approaches, retailers can create a win-win scenario where financial performance improves alongside progress toward environmental objectives — proving that profitability and sustainability can reinforce rather than compete.

The financial impact

Food waste creates a significant financial burden that affects virtually every aspect of grocery retail operations. When products go unsold due to spoilage, retailers incur a cascade of additional expenses that compound the financial impact beyond just the lost product cost.

Food waste impacts grocery retailers’ profitability through multiple channels:

- Product cost: The direct expense of purchased inventory that goes unsold.

- Disposal costs: Additional expenses related to waste management and processing.

- Labor costs: Time spent managing, rotating, and disposing of spoiled products.

- Lost sales opportunity: Revenue never realized from products that spoil before selling.

- Inventory carrying costs: Capital tied up in excess inventory that could be deployed elsewhere.

- Transportation inefficiency: Costs associated with moving excess inventory that ultimately goes to waste.

For many grocery retailers, these combined costs represent one of the most significant variable expenses in their operations. Even modest reductions in food waste can translate to meaningful increases in overall profit margin — a substantial gain in an industry with traditionally thin margins.

Challenges facing grocery retailers

The complex nature of grocery retail operations creates numerous challenges that contribute to food waste and increase costs throughout the supply chain. Addressing these fundamental issues requires understanding their interconnected nature and implementing targeted solutions.

Inefficient inventory management practices

Many grocery retailers still rely on outdated approaches to inventory management that perpetuate waste. With manual processes, store managers frequently respond to stockouts by overordering, creating a cycle that leads to excess inventory followed by inevitable waste. Manual ordering procedures simply can’t incorporate the data or visibility needed to prevent the uncertainty that encourages buffer ordering “just to be safe.”

Balancing availability and waste

Grocery retailers constantly face the challenge of balancing two competing priorities: maintaining product availability to satisfy customer expectations while minimizing excess inventory to reduce waste. This balancing act becomes particularly challenging with fresh products, where customer expectations for quality and abundance clash with short shelf lives and variability.

Unique challenges of fresh product management

Fresh categories present specific challenges beyond those found in center store management. Products within fresh categories expire at different rates, and variations in quality create complexity. Consumer purchasing of fresh items fluctuates more unpredictably than center store categories, while higher weekend demand creates spikes that require carefully planned inventory management to prevent Monday spoilage.

Promotional activities further complicate fresh inventory management, as they’re notoriously difficult to forecast accurately. Without precise mapping of promotional strategy and optimal pricing, retailers often order significantly more than needed, leading to excess inventory that must be deeply discounted or wasted.

Operational inefficiencies

Beyond inventory management, retailers face operational challenges that contribute to waste throughout their operations. Staff shortages create labor constraints that limit the time available for proper inventory management and fresh product care.

At the same time, poor layout and workflow result in inefficient store processes that increase handling time and product damage during restocking. Lack of coordination between distribution centers and stores creates a disjointed supply chain that fails to optimize inventory across all locations. Many retailers struggle with limited data utilization, unable to leverage available information for proactive waste reduction and inventory optimization.

“Managing food waste isn’t just about what happens at the shelf—it’s about getting the strategy right across the entire grocery supply chain. From sourcing and tax considerations to transportation, inventory systems, and store operations, every decision impacts waste, profitability, and customer trust.”

Brian Baker, Managing Director, Deloitte

How smarter inventory management cuts costs

The path to substantial waste reduction requires a fundamentally different approach to inventory management. By implementing modern, technology-driven solutions, retailers can dramatically reduce waste-related costs while simultaneously improving product availability and freshness.

Accurate demand forecasting

Modern forecasting capabilities allow retailers to predict customer demand with unprecedented accuracy through sophisticated algorithms and machine learning. Day-level forecasting captures demand variations throughout the week, while fresh-specific algorithms account for the unique nature of fresh product demand, including seasonality and substitution behaviors.

With AI-driven demand forecasting, retailers can significantly reduce forecast error compared to traditional methods, directly translating to reduced waste and improved availability.

End-to-end supply chain visibility

Complete visibility across the supply chain connects all inventory decisions from supplier to shelf. Multi-echelon planning optimizes inventory levels across distribution centers and stores, while predictive inventory models, such as RELEX True Inventory, identify and correct inventory discrepancies. Exception-based management focuses attention on inventory issues requiring intervention, allowing staff to address potential waste situations before they occur.

This comprehensive approach ensures that waste reduction efforts are coordinated across all operations rather than creating isolated improvements that might simply shift waste from one area to another.

“The challenge isn’t that retailers don’t address food waste, but that most tackle it in silos. Those who take a connected, end-to-end approach—leveraging data, automation, and smarter planning—will not only cut waste but also drive efficiency, protect margins, and strengthen their competitive position.”

Brian Baker, Managing Director, Deloitte

Dynamic inventory optimization

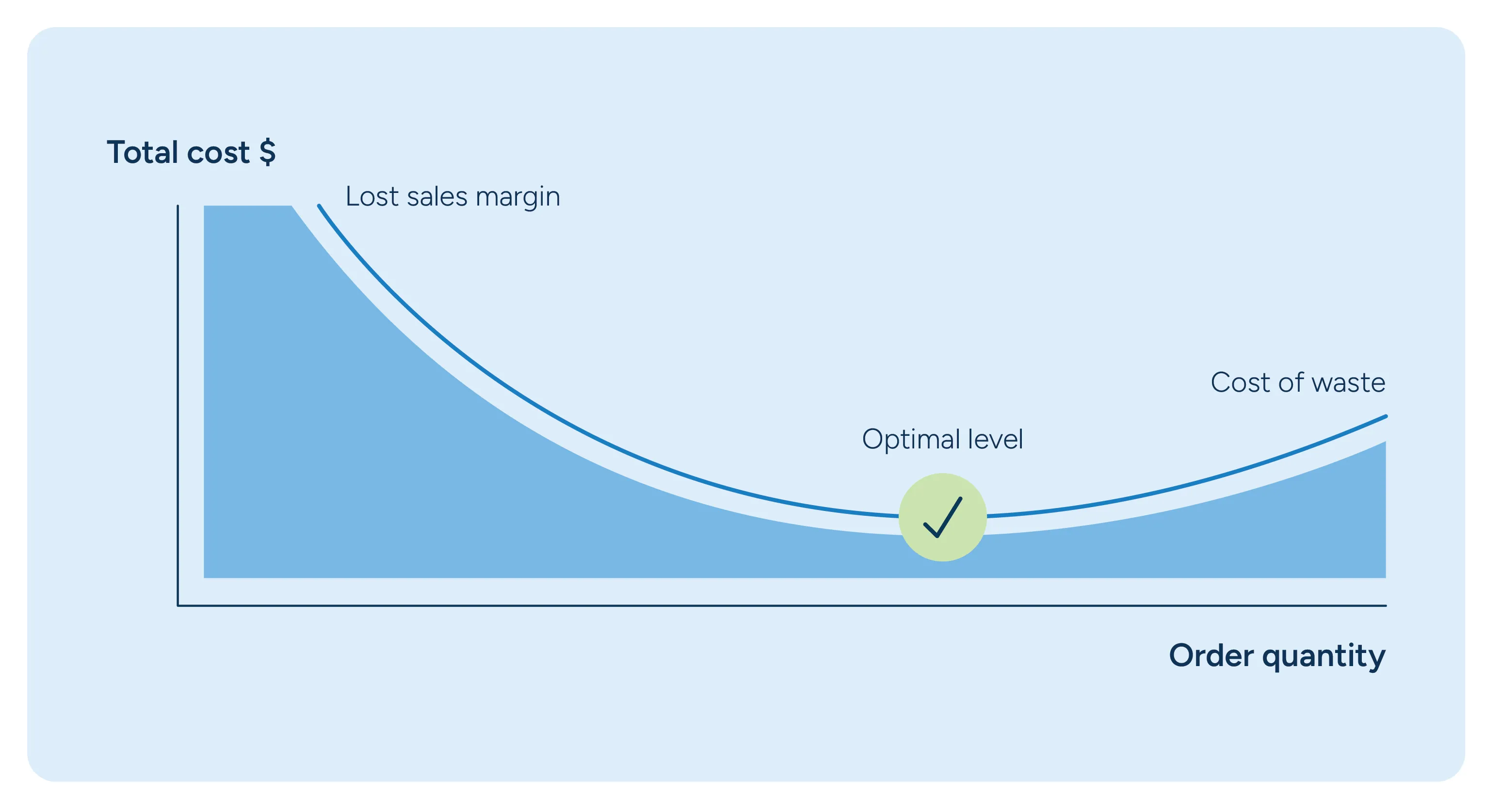

Dynamic inventory management revolutionizes how retailers manage fresh products by continuously optimizing inventory levels. Adaptive safety stock adjusts buffer inventory levels automatically based on expected demand, while spoilage-based ordering incorporates expected product spoilage into order calculations. Financial optimization balances the cost of waste against the cost of stockouts, finding the optimal inventory level that minimizes total cost.

These capabilities enable retailers to maintain the delicate balance between availability and waste, automatically adjusting orders to minimize overall costs while maintaining service levels.

Deeper supplier coordination

Breaking down silos between retailers and suppliers creates opportunities for more efficient production planning. When suppliers receive consistent, accurate orders based on actual demand patterns, they can grow and produce exactly what’s needed. This improved coordination reduces variability in ordering, allowing suppliers to plan more effectively and avoid overproduction that leads to waste.

Improved supplier coordination supports faster responses to disruptions caused by weather events, transportation issues, or other supply chain challenges. When retailers can quickly identify alternative sources or redistribute inventory based on real-time information, they minimize the risk of product spoilage throughout the system.

“Grocery retailers sit at the center of the food supply chain, and their role in reducing waste extends beyond store operations. From improving coordination with suppliers to streamlining inventory and enhancing demand forecasting, retailers can turn food waste reduction into a financial advantage.”

Andrew Harig, VP Tax, Trade, Sustainability & Policy Development, FMI – The Food Industry Association

Cutting waste and costs through technology

Implementing effective waste reduction strategies requires technology specifically designed to address the unique challenges of fresh inventory management. RELEX offers a unified retail planning platform that specifically addresses food waste challenges and grocery retail cost reduction. The platform’s integrated approach enables grocers to optimize their entire operation, from demand forecasting to store execution, with capabilities specifically designed for the complexities of fresh categories.

Fresh optimization with accurate forecasting

Fresh optimization minimizes spoilage costs by aligning fresh product inventory with precise demand forecasts.

- Batch-level freshness management: Tracks and manages individual product batches with unique shelf-life characteristics.

- Spoilage projection: Accurately forecasts expected spoilage for informed ordering decisions.

- Adaptive safety stock: Automatically adjusts safety stock levels based on expected demand.

- Financial optimization: Balances the cost of waste against the cost of stockouts.

- Make-to-sell and break-to-sell support: Enables accurate ingredient forecasting for prepared foods.

Fresh optimization helps retailers reduce spoilage by 10-40% while improving product availability.

“By leveraging AI-driven forecasting, automation, and real-time supply chain visibility, grocers can reduce losses, improve operational efficiency, and meet rising consumer expectations for sustainability—all while strengthening their bottom line.”

Andrew Harig, VP Tax, Trade, Sustainability & Policy Development, FMI – The Food Industry Association

More efficient store execution

RELEX mobile solutions empower store staff to manage fresh products intuitively and effectively. The user interface simplifies order review and adjustment, enables quick inventory verification, and focuses on items requiring intervention through exception-based workflows.

True Inventory provides real-time visibility into actual on-hand quantities, allowing for targeted inventory counts that improve accuracy without requiring complete store counts.

Store teams using RELEX mobile tools typically save 4-5 hours daily on ordering and inventory management tasks, freeing them up for other tasks.

Emissions insights with CO2 analytics

CO2 Analytics provides insights into carbon emissions from inventory-related activities. The system monitors emissions from supply chain activities, quantifies the environmental impact of food waste, and identifies opportunities to reduce emissions through transportation optimization.

When order accuracy increases, retailers need fewer trucks to transport excess inventory, lowering their carbon footprint. The resulting waste reduction simultaneously improves both financial and environmental performance.

By connecting waste reduction to environmental impact, CO2 Analytics helps retailers simultaneously achieve financial and sustainability goals.

A smoothly operating supply chain with CO-MRP

CO-MRP (coordinated multi-echelon replenishment planning) enables coordinated ordering to optimize inventory across the supply chain. The system maximizes delivery efficiency through truckload optimization, aligns store and distribution center orders, and optimizes order frequency to reduce waste.

With CO-MRP, retailers can reduce transportation costs while improving product freshness through more efficient supply chain operations.

See the full story with RELEX Diagnostics

Through advanced analytics, RELEX Diagnostics enhances visibility into inventory, stockouts, spoilage, and excess. The system identifies waste patterns and root causes, pinpoints excess inventory opportunities, and provides specific recommendations for improvement.

By identifying key problem areas—such as consistently late suppliers or persistent inventory inaccuracies—diagnostics help retailers unlock efficiency improvements that get products to stores faster and more reliably. Faster product delivery leads to fresher products available for customers and longer shelf lives, reducing waste.

This analytical capability ensures that waste reduction initiatives continue to deliver results over time rather than achieving initial improvements that fade as attention shifts elsewhere.

Case study: Oda’s strategic transformation

Oda, Norway’s largest online grocery retailer, faced significant challenges with food waste and operational efficiency before implementing RELEX solutions.

The challenge

Before implementing RELEX, Oda was caught in a reactive inventory management cycle. Regular sellouts at the beginning of the week led to overordering in response, which created excess inventory by mid-week. This excess inventory frequently led to spoilage later in the week as products reached their expiration dates before selling. Staff spent significant time on reactive order adjustments, while poor inventory visibility hampered effective decision-making.

The solution

Oda implemented RELEX for forecasting, replenishment, and promotions solutions with clear objectives: increase product availability, optimize procurement processes, and reduce food waste. They leveraged the RELEX Business Rules Engine to configure and automate their ordering, allowing them to define complex decision-making processes based on predefined rules and conditions.

The results

The implementation of RELEX delivered significant operational improvements:

- Time savings: 4-5 hours saved per planner daily through automation.

- Reduced food waste: Significant reduction in spoilage through more accurate ordering.

- Improved analysis: Planners shifted from manual ordering to value-added analysis.

- Enhanced flexibility: Easily adaptable system accommodated Oda’s evolving needs.

- Systematic improvements: Breaking the cycle of reactive ordering and spoilage.

“At Oda, flexibility is important because our needs change constantly due to the fast-paced nature of our business,” said Simon Svensson, Logistics Developer at Oda. “RELEX has allowed us to automate all our order proposals, drastically cutting down on manual processes. This automation has boosted our efficiency and significantly reduced food waste through more accurate and systematic ordering.”

Key metrics for waste reduction

Effective waste reduction requires precise measurement of progress and outcomes. The right metrics ensure accountability and provide guidance for continuous improvement efforts.

These essential key performance indicators offer a comprehensive view of waste reduction progress.

- Cost of waste as a percentage of sales tracks the direct financial impact of waste relative to revenue, providing context for how waste affects overall business performance and profitability.

- Forecast accuracy at day level measures how precisely demand is predicted for fresh items daily, helping retailers identify opportunities to improve ordering and reduce both stockouts and excess inventory.

- Inventory turnover in fresh departments shows how quickly products move through the system, identifying slow-moving items that may be at higher risk of spoilage and helping optimize assortment decisions.

- Service level tracks orders fulfilled completely and on time, providing visibility into overall supply chain effectiveness and highlighting improvement opportunities while reducing waste.

- Food waste reduction percentage measures progress in reducing total waste volume against the established baseline, allowing retailers to quantify improvements and communicate results to stakeholders.

If your waste reduction efforts work, you should see improvements in all these areas. If not, you should rethink your approach to reducing store waste.

The profit opportunity in waste reduction

Reducing food waste represents one of the most significant opportunities for grocery retailers to improve profitability while advancing sustainability goals. Food waste directly impacts the bottom line through multiple channels, making its reduction an essential strategy for retailers seeking to improve financial performance.

RELEX provides grocery retailers with advanced capabilities to tackle food waste at its source through technology specifically designed for fresh inventory management. By breaking down silos, a unified platform with end-to-end visibility helps retailers prevent overordering while maintaining optimal product availability. Implementing these solutions delivers multiple business benefits:

- Significant cost reduction: Cut waste-related costs through more accurate ordering.

- Improved operational efficiency: Save 4-5 hours per planner daily through automation.

- Enhanced product freshness: Ensure fresher products through optimized inventory management.

- Reduced environmental impact: Decrease carbon footprint through less food waste.

- Improved overall profitability: Directly impact the bottom line through multiple efficiency improvements.

Food waste reduction is no longer just a sustainability initiative — it’s a financial imperative that directly impacts the bottom line.