How to improve fresh food inventory management with unified central planning and store execution

Mar 14, 2024 • 7 min

Fresh food retailers: Which would you rather have spoil — your food or your customers’ sentiment?

The clear answer is “neither.” But for many teams, fresh food inventory management too often feels like choosing between two equally undesirable outcomes. Keep availability too high, and spoilage occurs. Only order what’s needed when it’s needed, and stock-outs occur.

Neither scenario impresses customers. Both hurt a retailer’s bottom line.

Fortunately, it’s a false dilemma. Modern inventory planning and store execution solutions help retailers tread a middle ground, emphasizing freshness to improve customer satisfaction without flooding shelves with soon-to-expire food products. To conquer fresh food inventory management challenges, retailers must take advantage of every tool at their disposal — or, potentially, just the right digital one.

What is fresh food inventory management?

Fresh food inventory management is the process of tracking and optimizing the stock of perishable goods to reduce waste and ensure availability. Fresh goods management is particularly interesting to supermarket and grocery retailers, who manage a broad assortment of fresh products. Yet every retailer — from health food stores to convenience stores — that deals with fresh items in any volume requires some level of inventory management strategy.

Efficiency and accuracy in fresh food management are vital to a retailer’s success. Competition is fiercer than ever, and stock-outs create unhappy customers more than willing to seek their wares from a nearby competitor. But the fear of understocking often results in the opposite, with over-ordered fresh goods leading to costly spoilage in a category with razor-thin margins.

Fresh food inventory management challenges

General inventory management involves a slew of challenges. The rigors of demand forecasting, inventory optimization, and general supply chain disruptions make it difficult to achieve cost and operational efficiency in managing any range of items.

The introduction of fresh food adds new wrinkles of complication to the process, including:

- Product perishability. Fresh foods have a short shelf life, requiring rapid turnover and precise timing in logistics to minimize spoilage.

- Batch and lot tracking. Companies must track specific batches or lots for food safety recalls, quality control, and expiration date management.

- Seasonality. Seasonal availability and demand fluctuations of certain fresh foods require consideration in planning and process development.

- Waste management. Teams must devise strategies to minimize waste through donation, composting, or other means to avoid high spoilage rates.

- Supplier reliability and quality variability. Staff must ensure consistent quality and reliability from suppliers, as the quality of fresh food can vary more than non-perishable goods.

- Dynamic pricing. Fresh inventory management teams must constantly adjust prices based on freshness, quality, and remaining shelf life to encourage the sale of soon-to-expire stock without compromising food safety.

Even after reckoning with every fresh-related difficulty, businesses must still find a way to manage the staff involved. Fresh food inventory planning is tricky enough, but the key to profitability lies in aligning accurate planning with efficient execution.

3 essential strategies for optimizing fresh food inventory management

Supply chain planners and frontline teams often struggle to balance just-right inventory, precise item management, and timely on-shelf replenishment. Central planning and store teams have traditionally tackled these challenges in silos, treating high-level forecasting and store-level execution as separate domains. This may suffice for slower, more predictable product categories, but falls short of achieving the desired outcomes for perishable departments.

The key to consistently higher levels of on-shelf availability and product freshness — without the costly misstep of over- or understocking — lies in unifying forecasting and store execution software. This unification allows fresh food retailers to:

1. Improve fresh food inventory management through more accurate inventory data

The prevalence of shrinkage and the short shelf lives of fresh items require demand forecasting teams to leverage real-time insights into store-level data to stay on top of stock. Fresher data points can combat these issues, such as current on-shelf availability and updated expiration status. Otherwise, stale and inaccurate data weigh down demand projections, resulting in stock level imbalances.

The best way to achieve this level of insight is to empower frontline teams with a mobile retail execution tool that synchronizes with a retailer’s inventory software. This allows frontline teams to quickly identify and act on discrepancies between purported inventory data and actual on-hand inventory levels.

Imagine that a store associate is tasked with restocking pumpkins for an upcoming holiday. According to the inventory data from their execution tool, there should be 30 pumpkins on the shelf — but there are only 25. In addition, some of the produce is starting to go bad.

Half of the pumpkins risk spoiling before customer needs are met. Central planning might continue ordering the same volume and selection before seeing a more regular pattern in the data. By then, customers may have moved on to a competitor to fulfill their needs.

An associate can use a unified retail execution platform to immediately flag or reorder the five missing pumpkins through their mobile device, resulting in:

- Quicker replenishment.

- Better on-shelf availability.

- More accurate inventory projections.

Store associates can also give the central team insights into when local holidays are more likely to affect them. That way, fresh produce is available at the optimal time when customers are looking, and nothing spoils or is over- or understocked.

The more detailed the data, the better the in-store experience is for shoppers.

Fresher data enables retailers to optimize demand planning for each store and consider factors such as seasonality, local buying behaviors, and more. The more detailed the data, the better the in-store experience is for shoppers.

READ MORE: How data best practices can improve inventory management and forecast accuracy

2. Empower store teams through more efficient merchandising execution

Today, frontline teams are asked to do more with less, given the current workforce climate. This stress leads to turnover issues and lengthy onboarding times in a labor force where finding the right skills is already difficult. Overlapping tasks, heavy workload, and an overreliance on seasoned staff can lead to employee burnout and resignation.

Combining supply chain planning and store execution into one shared platform can alleviate many of these common workforce issues. Smoother delivery peaks and balanced deliveries through central demand planning help store operations teams take advantage of low-traffic days for handling inventory and busy days for customer service.

On top of effectively delivering stock, in-store collaboration tools can help employees prioritize tasks to use their time and skills where they are needed the most, such as interacting with customers and collecting fresh food inventory data. Fresh food retailers who let technology handle time-consuming, data-driven tasks free up their store staff to focus on the human tasks that add the most value to the store experience.

In-store collaboration tools can help employees prioritize tasks to use their time and skills where they are needed most.

Collaboration tools also help lower the skill gap between employees. Not relying so much on the most knowledgeable staff balances the workload. More seasoned employees are less likely to leave, and newer employees catch up to speed more quickly.

Visibility between in-store and central planning times reduces clashing and allows each team to benefit from the insights of the other to improve assortment, deliveries, and task management. A shared platform keeps all the data in one place so the overall network can create better forecasts while cutting out unnecessary or redundant work.

3. Collaborate more effectively

Central planning and store teams are generally siloed but are still part of one cohesive whole with a shared goal. Investments in collaboration allow each team to do what they do best, with the entire system working in harmony.

Store operations can give their valuable in-field insight and expertise, while central planning experts can focus on timing fresh deliveries and ensuring the correct assortment.

With a strong team holding the right tools at both ends of replenishment, fresh food inventory management becomes much easier to manage — resulting in happier customers, lower operational costs, and greater profitability.

READ MORE: How to improve customer centricity with in-store assortment collaboration

Tackle fresh food inventory management challenges with unified demand planning and execution

Modern fresh food and inventory management problems require modern solutions. Retailers need a digital tool that handles broader inventory management needs like accurate forecasting and automated replenishment and couples it with fresh item-specific features.

RELEX is the foremost expert in fresh food inventory management and has built powerful solutions for retailers across the globe. Consider Britain’s largest regional supermarket, Booths. The company used RELEX to reduce the spoilage of chilled food items — a category accounting for around 20% of total wastage — by more than 20%.

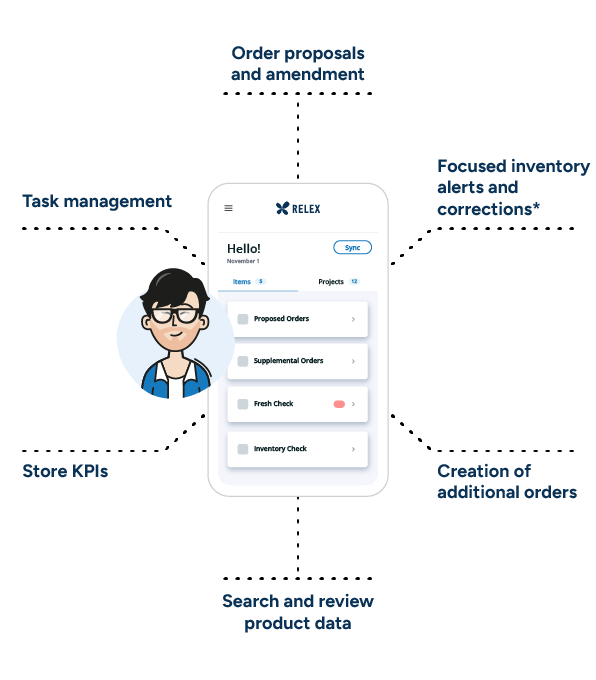

The RELEX approach to effective inventory management emphasizes the need for better communication between internal teams. In-store execution app RELEX Mobile Pro provides data-informed insights into ordering and replenishment for teams on the go. The app grants staff visibility into batch spoilage projections and urgent stock needs while roaming the store floor, ensuring essential inventory information is always in hand.

The best part? The functionality that makes RELEX Mobile Pro essential in increasing efficiency in fresh item management is also useful in optimizing the management of center store products.

For those struggling with manual processes in the face of increasing complexity and competition, a fresh approach to inventory management can make all the difference.