Waste not: How grocery retailers transform fresh produce from margin-eater to high performer

May 24, 2024 • 8 min

The quality and availability of fresh produce can make or break a grocery store. In fact, 51% of produce shoppers are looking to increase their fruit and vegetable intake, even through snacking, so there is certainly opportunity for market differentiation here.

But planning fresh fruits and vegetables entails a host of considerations that traditional spreadsheet-based inventory management methods simply cannot cope with — from inventory shrink to complex spoilage timelines and all the associated data issues. Because of these complexities, the fresh item management process is often managed separately from the rest of the store. It requires frequent manual inventory checks and local expertise from experienced employees who rely on gut instinct to place orders – and who often receive little or no information about upcoming sales and promotions.

This leaves fresh retailers in a quandary – how can they manage fresh produce in a way that mitigates stockouts and waste, maximizes freshness and availability, and streamlines planning and store execution?

Many are turning to retail planning software, but when they’re scouring the market for the best technology partner, how can they be confident their solution will deliver ROI?

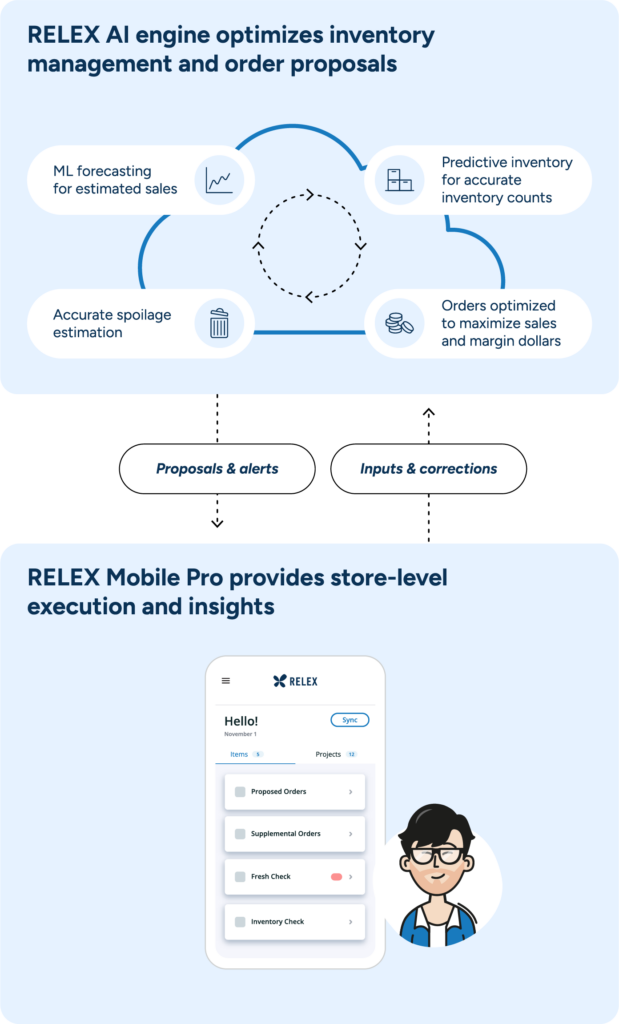

With years of experience in the grocery industry, RELEX has developed a two-part model that eliminates those planning headaches. The first part is an AI engine that is specially trained and adapted to overcome grocery challenges – especially those of fresh produce. The second is a mobile application that ensures those AI-driven insights reach the store floor, guiding employee task prioritization and collecting store-level information to enhance planning decisions.

In this way, grocery retailers can make the produce aisle a major sales driver, encouraging repeat customers and maximizing efficiency, availability, and freshness.

Under the hood: How the RELEX AI engine makes fresh produce your store’s star performer

RELEX has been developing and using AI since our inception. (In fact, we invest almost 30% of our revenue back into R&D.) We’ve built a comprehensive AI solution tuned to the needs of the grocery industry.

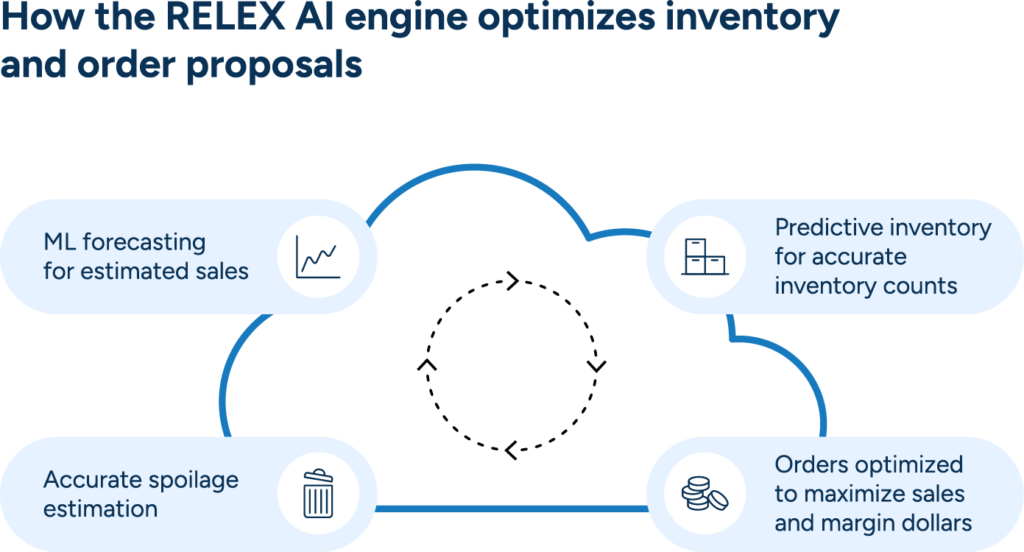

This platform unifies and optimizes planning across departments in three ways:

- It provides machine learning-based forecasting capabilities for more accurate and responsive forecasts.

- It enables predictive inventory to preempt stock imbalances.

- It calculates spoilage estimates and optimizes orders to maximize sales and margin dollars.

Machine learning-based forecasts for fresh products

The machine learning algorithms in the RELEX forecasting solution are extensively trained on fresh products – from dairy to deli and everything in between. So how do they tackle fruit and vegetable forecasts that battle inventory shrink, uneven spoilage, and poor or nonexistent store-level data?

The ML-based system is equipped with fresh optimization capabilities that calculate accurate order proposals daily so that retailers can hit availability, spoilage, and margin targets.

Its success lies in its processing speed, data, and AI decision-making.

First, from the bottom up, the RELEX forecast is built differently. It rests on an embedded database, allowing for more rapid transactional processing. Traditional systems use separate databases – meaning that any calculation requires sending data back and forth between databases and applications. This process gets slower and more cumbersome as data grows and as calculations become more complex.

The RELEX embedded database, however, sits inside the Forecasting & Replenishment application, enabling calculations within the application itself. This eliminates the need for all those clunky, time-consuming transfers and accelerates the entire process for faster responses to market changes and disruptions.

READ MORE: Pushing the boundaries of data processing

Second, RELEX machine learning algorithms have been trained on years of grocery data from some of the largest grocers in the world, analyzing consumer trends and product behaviors. Then for each customer, the system uses up-to-date data, such as weekday demand variations, to fine-tune its calculations.

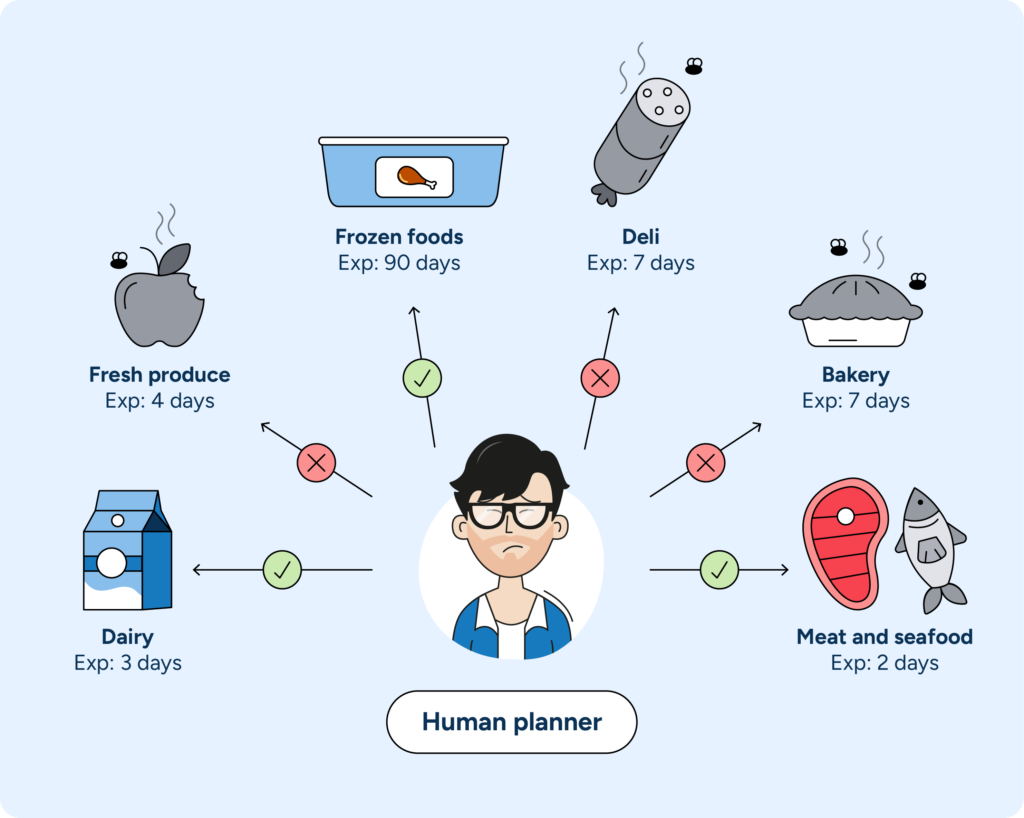

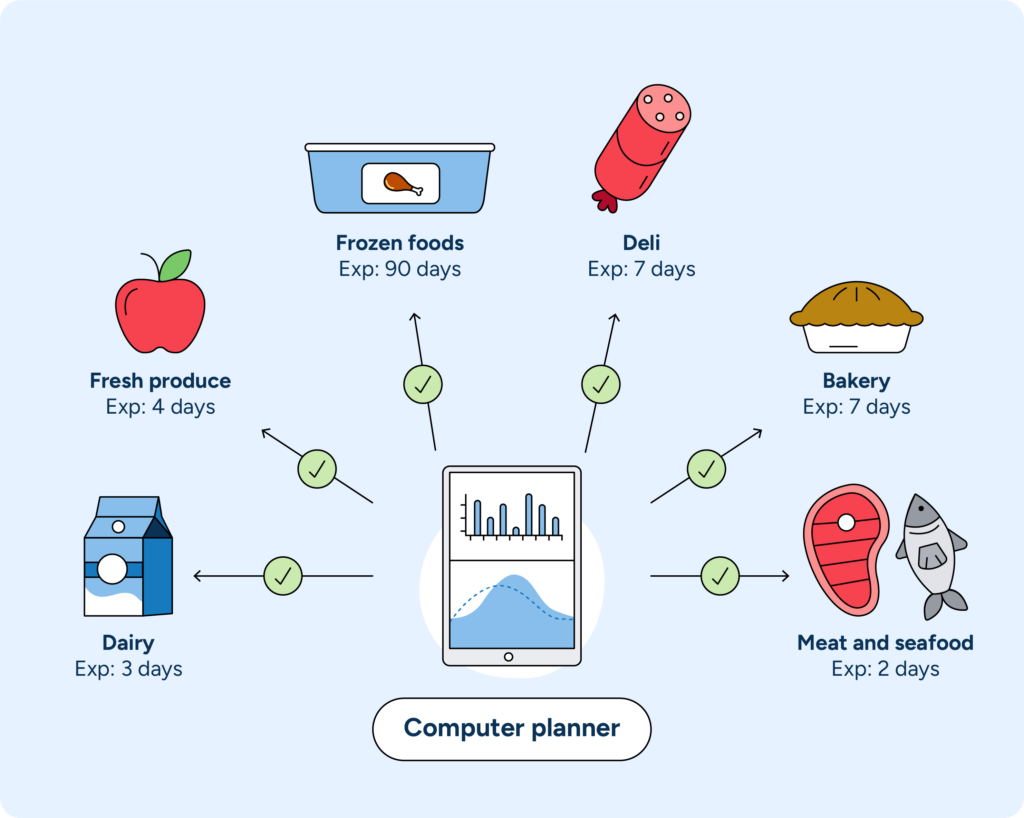

Moreover, AI accounts for a multitude of demand-influencing factors that a human could never analyze efficiently and promptly. Take, for instance, the varying spoiling times for fresh products. Even for this single consideration, the amount of data would overwhelm a human planner.

RELEX AI ensures nothing slips through the cracks, incorporating each variable into its calculations for maximum accuracy.

This combination of rapid processing, high-quality data, and powerhouse AI-driven computing means that, even in a fast-moving environment like fresh produce, planners can calculate forecasts that accurately predict and meet customer needs. This reduces spoilage, maximizes availability, and improves freshness. It also keeps manual planning to a minimum, making it easier for companies to adapt and scale.

By using ML-based forecasting for fresh produce, grocers can:

- Increase availability

- Optimize inventory

- Reduce manual work

- Achieve better visibility and transparency

- Future-proof their supply chain with adaptability and scalability

Predictive inventory – how machine learning ensures accurate inventory data and orders

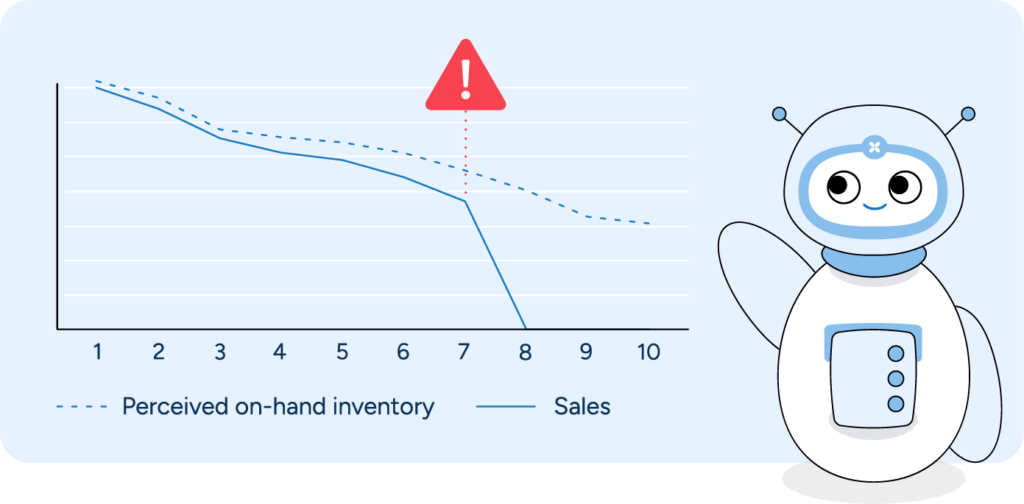

RELEX uses predictive inventory to drive operational efficiency. Using machine learning, the system identifies anomalies and creates a more accurate view of on-hand inventory.

Predictive inventory provides store operatives with a list of prioritized tasks by:

- Detecting phantom inventory through sudden sales drops for items with positive on-hand inventory levels.

- Prompting inventory count recommendations at regular intervals.

- Configuring retailer-specific tasks and best practices, such as tracking batch spoilage and assigning markdowns.

Predictive inventory also reduces the need for manual inventory counts and order corrections. Instead, it automatically generates order calculations based on its high-quality balance estimates. These accurate inventory records help it improve accuracy and prevent lost sales by correcting stockouts promptly.

With ML-based predictive inventory, retailers:

- Reduce time-consuming inventory management tasks through focused task lists

- Free up store associates for customer service-oriented tasks

- Prevent lost sales by detecting stockouts

- Improve ordering accuracy

Accurate spoilage estimation and cost-optimized ordering

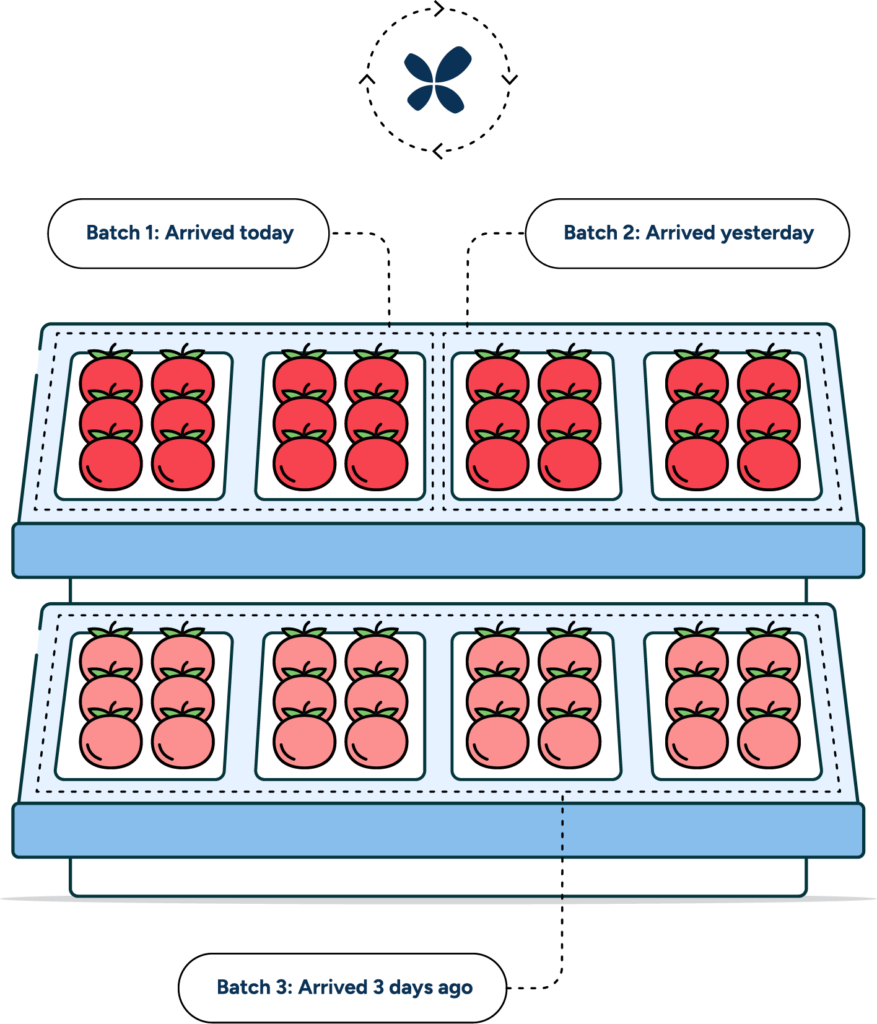

RELEX estimates the upcoming spoilage rate of fresh products by analyzing spoilage at the batch level. It uses machine learning algorithms to estimate the FIFO (first-in, first-out) rate based on how consumers pick products in store, identifying what percentage of shoppers buy from the oldest batch versus the newest.

For example, let’s say your store recently received three batches of tomatoes. One batch arrived today, one arrived yesterday, and the oldest arrived three days ago. RELEX tracks the expiration date for each batch, based on the delivery, sales, and spoilage data. If the batches are not consumed before expiring, they are expected to spoil and are considered in the order projections. RELEX uses the defined FIFO rate to fill demand from the oldest batch first.

In this way, RELEX creates a better picture of inventory and expirations to calculate more accurate replenishment orders. This reduces waste, decreases substitution and lost sales, and improves product quality and availability.

By using machine learning capabilities, grocery retailers can:

- Improve visibility into inventory freshness.

- Replenish fresh products more accurately.

- Reduce waste and maximize profitability.

- Decrease substitution and lost sales.

- Improve availability and freshness to drive sales.

Read more: The Complete Guide to Machine Learning in Retail Demand Forecasting

RELEX Mobile Pro – ensuring store execution of AI-driven plans

The AI platform optimizes inventory management and order proposals for every item in every aisle. Successfully managing fresh produce requires putting those insights into the hands of store employees.

RELEX Mobile Pro is not just a transition from pen and paper to a screen. It puts the AI engine’s powerful data insights directly into the hands of store employees and incorporates their input to continuously optimize decision-making.

Managing daily tasks with RELEX Mobile Pro

To facilitate daily ordering and inventory management, Mobile Pro has an intuitive, navigable interface that makes it easy to view and drill down into data. It also delivers offline capabilities so employees can complete tasks, even in cellular dead zones.

Backed by insights from the AI engine, Mobile Pro provides a clear overview of alerts and corrections related to inventory management. The AI engine tracks and calculates balance counts, spoilage, phantom inventory, and order proposals. Mobile Pro receives this data and delivers it as digestible, actionable insights, even for inexperienced store associates. It helps employees prioritize by generating a recommended task list, highlighting inventory exceptions, and outlining schedules. This automation increases efficiency and alleviates arduous manual processes, so employees can focus more on customer service.

Plus, Mobile Pro provides structured avenues for store feedback, transmitting new data back to the AI engine. For instance, a store employee can update on-hand inventory. This data, in turn, can be used directly to refine suggested order quantities. By learning and understanding the reasons behind store-level anomalies and product behaviors, the system can adjust forecasts, rebalance inventory, and tune replenishment proposals.

Making fresh produce the keystone of grocery retail

Fast-moving, perishable items like fruits and vegetables carry inherent planning challenges. For many grocery stores, this makes planning fresh produce a siloed operation, requiring intense manual monitoring and relying heavily on experienced labor.

With RELEX, grocery retailers delegate data-detangling and computational complexity to AI, reducing the impact of human error, waste, and inefficiency. Demand planners have the rapid insights they need to calculate accurate forecasts, and store employees can trade painstaking, manual processes for optimal recommendations.

By integrating AI-driven planning with daily store-level tasks, the RELEX two-pronged approach helps teams counter the challenges of fresh produce and streamline operations. This improves freshness, availability, and efficiency to make the fresh produce aisle a hub of profit-boosting customer satisfaction.