Galexis is a Swiss pharmaceutical wholesale dealer with a huge assortment of more than 100,000 products. The market leader in health logistics supplies pharmacies, medical practices, drugstores, nursing homes and hospitals in Switzerland with medicines from two efficient DCs. Galexis implemented RELEX to increase automation, maintain availability at close to 100% and, at the same time, lower inventory. These are vital competitive factors in the pharmaceutical industry.

Background

The merchandise management system previously used by Galexis provided order proposals and forecast quantities based on historic sales, current inventory and other static parameters. This manual system highlighted shortages on store shelves, but wasn’t able to factor in seasonal variations or promotions. The level of automation was around 48%. Planners had to personally confirm every article – which took a great deal of time given the huge number of products and high stock levels. For that reason, automating replenishment was a high priority. Galexis needed a solution that could recognize seasonal variation and trends automatically and classify seasonal products accordingly.

Galexis also needed different forecasting methods for special situations and wanted to raise the inventory turnover while simultaneously lowering the general inventory level. Planners were to spend less time with routine orders, but be able to control product replenishment, assortment planning and master data maintenance independently. This way Galexis aimed to create an efficient exception management process.

“The project was a complete success. We now have an ambitious stock turnover and a high level of automation with high availability. RELEX made working together really easy for us.”

Corvin Kienle, Head of Operations, Galexis

A Successful Pilot Convinced Galexis

“We were won over to RELEX’s solution because it is highly flexible, highly customizable and is remarkably straightforward to use,” says Markus Handschin, Project Manager SCM at Galexis. “We can now make adjustments to processes ourselves, easily and quickly. We tested all our business processes during the three-month pilot project. It’s not often one is offered such a long pilot. We were impressed with RELEX from the outset. It performed very effectively. We felt very well supported throughout the whole process.”

After signing the contract, the RELEX project team worked with Galexis to assess the quality of the existing data and configure the interfaces. “Together with our customers we are looking closely at the data to find open orders in the merchandise management system, that are usually hard to detect. Thanks to RELEX’s ease of use Galexis’ staff are able to maintain and check the data themselves. We make it a priority to ensure that our customers can use the system wholly independently of us so that their success isn’t just sustainable but can also be built on over time,” says Dr. Timo Ala-Risku, Country Manager Germany at RELEX Solutions.

RELEX can calculate future demand using existing sales data and the seasonal profile of each store at shelf level. This also includes having optimized safety stocks for all exceptions defined by the user. “The system shows exactly which products are in the sales portfolio and which are still in the quarantine portfolio. Information is transparent and easy to understand,” says Jörg Rudolf von Rohr, Head of Replenishment at Galexis.

The system gives a warning when there are fluctuations in demand or possible stock outs are detected and will automatically propose an urgent delivery. RELEX’s proprietary SCM-optimized database allows the software to process data 100 times faster than conventional providers by enabling the use of in-memory computing. For example, the solution can calculate 50 million stock keeping units in less than two hours.

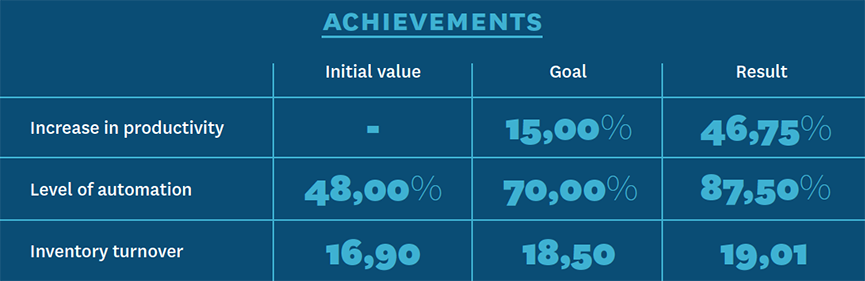

Results

“Galexis is our first Swiss customer, so we are especially pleased that the project has been such a clear success,” says Ala-Risku. The inventory turnover increased 12% in just four months. Galexis also benefitted from an automated replenishment, while automation rose from 44% to 88%. Availability remained high at over 98%. The initial goal was to increase the level of productivity by 15%, but quickly reached 47%. Employees are now able to create more orders in less time. “The project was a complete success.” says Corvin Kienle, Head of Operations at Galexis. “Important aspects of the project were ensuring the master data was sufficient and of high quality, as well as RELEX being able to guide us towards new operational processes. We now have an ambitious stock turnover and a high level of automation with high availability. RELEX made working together really easy for us.”