Grocers today are under enormous pressure to meet increasingly aggressive targets while managing a seemingly endless series of socio-economic disruptions. Razor-thin margins necessitate growing sales and slashing operating costs while minimizing spoilage and maintaining high availability.

Grocery retailers face a number of critical challenges:

- Consumer buying patterns continue to change as shoppers embrace omnichannel shopping, even in fresh categories.

- Fresh item quality and range are increasingly important to attract customers toward shopping the rest of the assortment.

- Labor and skills shortages have employers worldwide wondering how to attract and retain talented staff.

- Supply chain constraints make it difficult for grocers to maintain availability to meet customer needs.

- Pressure to minimize food waste is driven by both corporate citizenship and the influences of sustainability on consumer decisions.

In many ways, grocery, more than any other retail vertical, seems like an impossible balancing act: provide the freshest products and highest availability while trying to keep the financial and environmental costs of high inventory levels and food waste at bay — all despite the ground constantly shifting.

Despite the issues, retailers are still seeking to expand their fresh offerings. In our webinar, Staying Competitive in Fresh Retail, we cited research from FMI, the Food Marketing Institute, showing that 41% of grocery sales in 2022 came from fresh categories. Their research also shows significant investments in both space and workforce targeted directly at fresh expansion

RELEX’s Marc Koehler shares insights into retailer’s investments in the growth of fresh categories. Watch the full webinar for the whole story.

The increasing focus on fresh and retailers’ active efforts to grow this area of their business means that the issues they face will only become more complex and urgent unless they take steps to optimize their replenishment processes to meet their goals.

1. Fresh management brings a unique set of challenges and requirements

Today’s retail supply chain must be agile, efficient, and responsive to changing consumer trends, which is a challenge under any conditions. But when managing highly perishable goods — that all have different spoilage rates down to the item level — supply chain optimization is mission-critical for grocery retailers.

1.1 Fresh depends on an adaptive strategy – easier said than done

Understanding why fresh items are so much more challenging to manage means understanding that different products require different strategic approaches:

- Fresh item strategy prioritizes adaptability: Maximize availability, freshness, and abundance of presentations while minimizing waste and the need for markdowns.

- Center store strategy prioritizes efficiency: Maximize availability while minimizing inventory and goods handling costs for items with no spoilage risk.

It’s a complicated endeavor to be adaptive while minimizing costs, as the current environment demands. The most obvious challenge is that fresh products spoil, so they can quickly drag down availability and customer experience while driving up waste and lost sales.

On top of the inherent risks of spoilage, consumer demand for fresh items can be highly variable and unpredictable, as shoppers often buy what looks good in-store. Who hasn’t thought something like “Oh, strawberries look good today!” and brought home an impulse purchase even they couldn’t have predicted?

The volatility of a complex supply chain is another challenge that significantly impacts fresh management. Variations across harvests and yields and transportation issues result in instability in the supply of fresh products, making it challenging to ensure availability meets consumer demand.

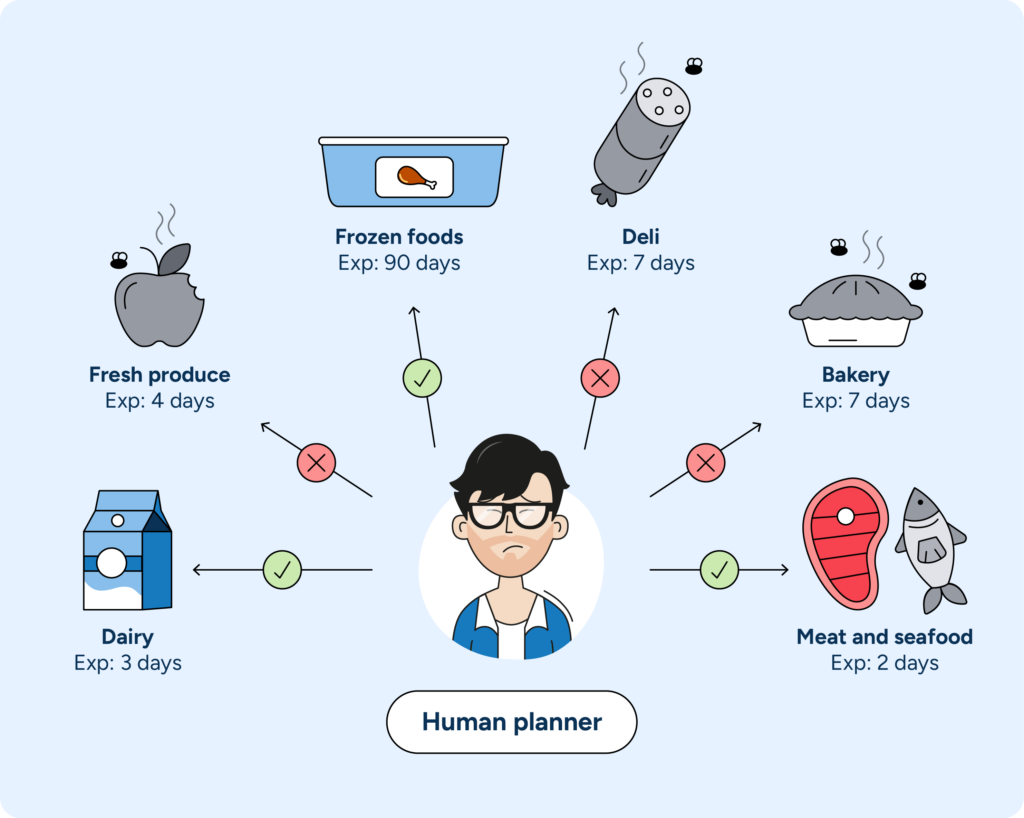

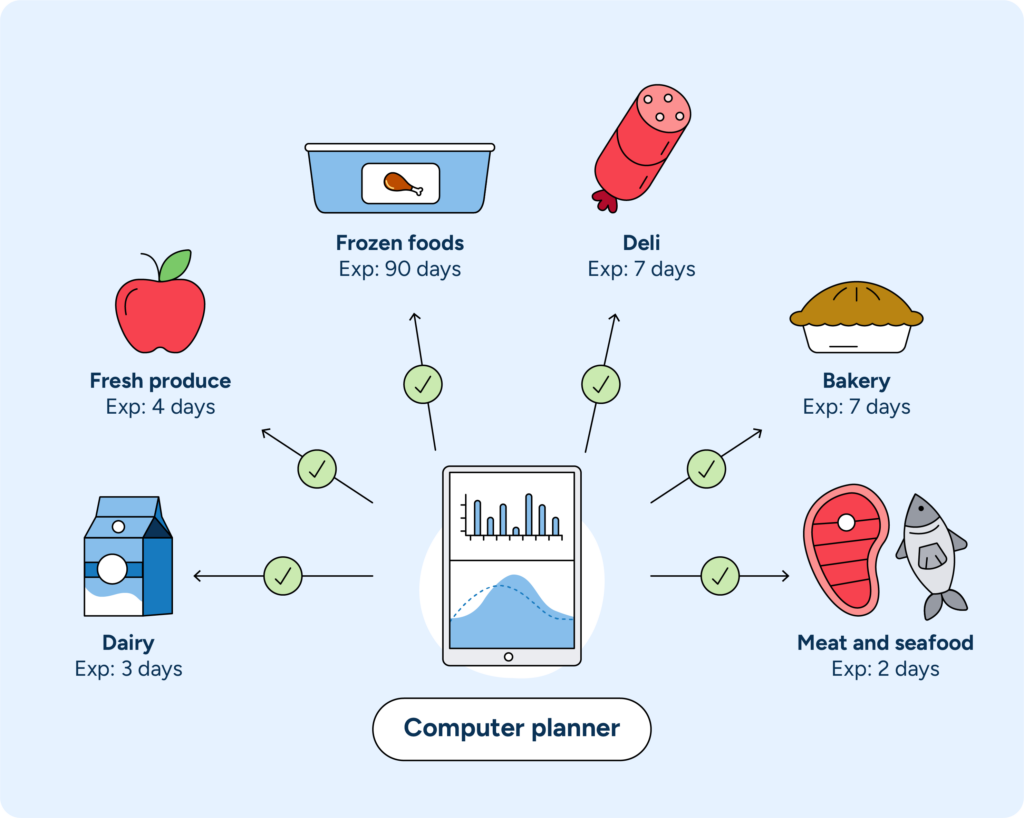

1.2 “Fresh” is not a single category but a diverse collection of products with unique characteristics

The term “fresh,” as it pertains to retail, covers a vast range of products and categories. Variations in spoilage rates and storage condition requirements across such a diverse assortment increase complexity and, in some cases, space and capacity needs.

Items as different as a carrot, a package of cold cuts, a bottle of milk, and a package of frozen tilapia have very different profiles, so much so that separate category teams manage them.

Depending on which type of fresh product they work with, planners may face different challenges:

- Products without individual expiration dates, such as loose vegetables, drive uneven, hard-to-predict spoilage.

- Products from batches with multiple expiration dates will expire at different times on the same store shelf.

- Unchecked shrink due to capacity issues and assortment size leads to poor inventory balances.

- Replenishment for make-to-sell or break-to-sell items must be managed alongside other orders.

- Challenges securing seasonal products can arise due to demand surges or supply constraints.

- High substitutability is especially relevant when customers shop around the assortment for the best-looking product rather than looking for a brand.

With so many considerations and complexities swirling in the mix, it certainly doesn’t help that, for most grocers, fresh inventory data is reliably unreliable. It doesn’t help that planning processes are also generally manual and siloed, with very little automation or data visibility to support busy personnel. Fortunately, modern innovations in planning technology have made the most difficult parts of fresh management far more manageable.

2. The pillars to fresh success

Fresh item management is undoubtedly a challenging endeavor, but by no means impossible. The most successful approaches to fresh replenishment always come back to the key pillars explored in this guide.

2.1 Accurate order proposals

Accurate order recommendations should be at the heart of any planning tool that hopes to help grocers master fresh replenishment. They help maintain optimal inventory levels by ensuring the right amount of inventory is ordered for each store in the network, preventing stock-outs and lost sales, as well as overstocking that leads to costly waste and spoilage.

Calculating the most accurate order proposal possible requires several essential elements:

- Forecast accuracy and granularity are the foundation for all replenishment but are mission-critical when dealing with the complex variations of managing fresh items.

- Understanding the balance of available stock is necessary for retailers to create order proposals confidently, and they need a way for store personnel to identify and log discrepancies and keep data current.

- Safety stock levels must be kept as low as possible to avoid spoilage while preserving availability.

2.2 Efficient store operations

It is important to note that grocery retailers operate different models. At one end of the spectrum are the centralized models, where the person placing orders plans replenishment for several stores. On the other end of the spectrum are the decentralized models, in which the person placing orders plans replenishment and operations for a single store or even department at a store. Further, for some retailers, these models can vary within departments and sub-departments, such as dairy and produce in fresh categories.

No matter the retailer’s operational model, store personnel have a crucial role in the story of fresh success. They need the right tools to enable accuracy and efficiency for placing orders and checking inventory levels, freeing up time for higher-value tasks such as maintaining appealing displays and serving customers.

2.3 Long-term and multi-echelon planning

While stores are critical as the front line, retailers can’t ignore the broader process optimizations necessary for long-term success. To see the most significant efficiency gains and cost optimizations, grocers need a single system capable of managing the entire portfolio—from center store goods to deli to fresh produce to packaged meats—to drive collective benefits. The system must support collaborative planning and execution across the end-to-end network, considering volumes, capacity, and bottlenecks from suppliers to distribution centers to stores.

3. Store order accuracy is the heart of effective fresh management

Replenishment is one of the most critical tasks for any fresh retailer but also the most difficult. Errors related to managing fresh items can be extremely costly, which is a significant concern as prices rise and consumers closely monitor their spending.

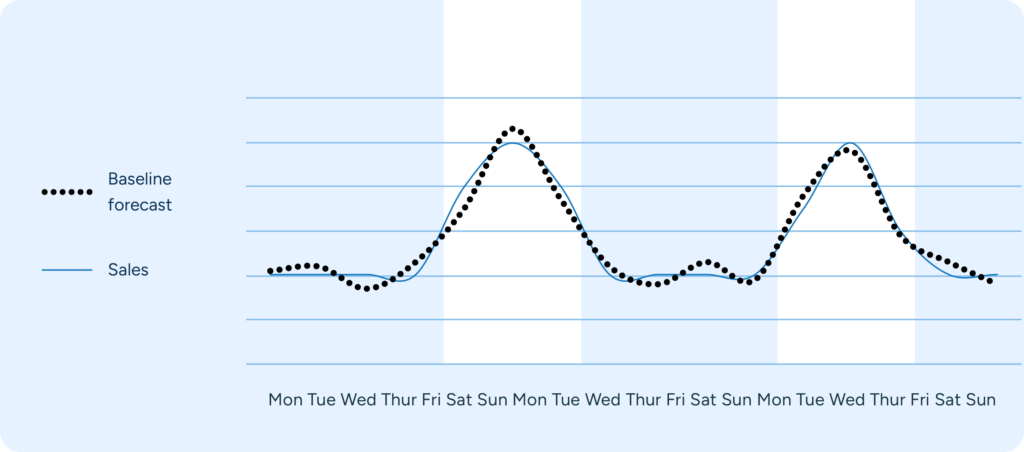

Without an exceptionally accurate forecast of future demand, it is impossible to prevent under- or over-ordering. Fresh retailers need at least day-level demand forecasting to capture demand variation throughout the week accurately — a critical capability when working with perishable products. Some ultra-fresh products may even call for intraday forecasting that supports multiple daily replenishments. AI-driven planning tools increase the speed and frequency at which grocers can analyze their data and build their plans.

If a store orders too little of a fresh product, they risk losing sales, which results in dissatisfied or even lost customers. However, if they order too much, the store risks spoilage, which is both a financial loss and an increase in grocery store food waste at a time when sustainability is a major initiative for many retailers. Further, unlike center-store products, there’s no buffer with fresh items, and retailers can’t store overstock in a back room or distribution center until needed.

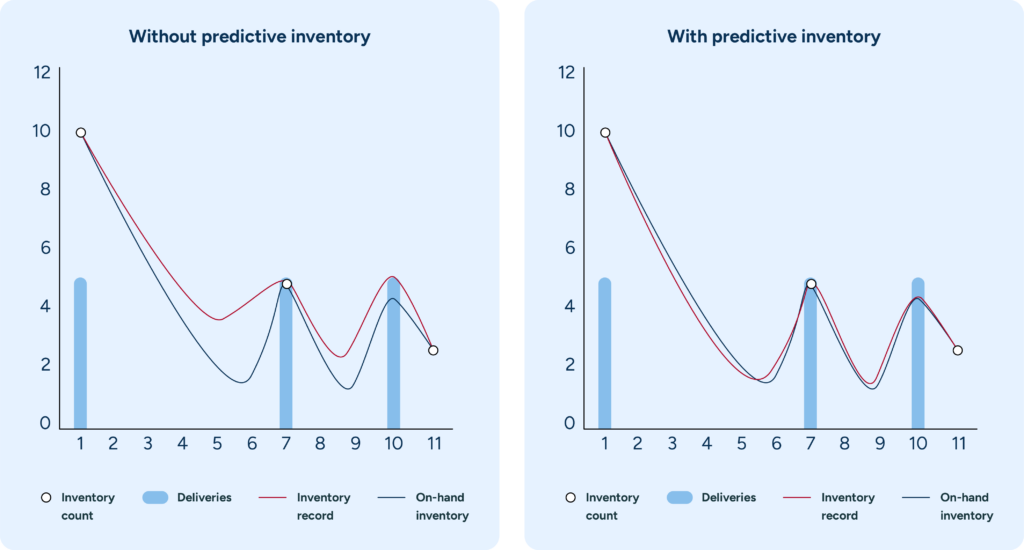

3.1 Predictive inventory models leverage store-level data to keep balance data current

The lack of accurate inventory balance data is one of the most frequent challenges we hear in the industry. Stores freque ntly see balance data degrade over time as products vaporize into theft, misweighing, spoilage, or other shrinkage without being captured in the inventory management system.

RELEX’s Alexandra Sandoval discusses the keys to order accuracy for fresh and grocery. Watch the full webinar for the whole story.

That’s where predictive inventory comes in, helping improve order calculation accuracy even when balance data is poor or perpetual inventory is lacking. Predictive inventory builds a “synthetic inventory” based on transaction data and in-store inventory checks to calculate order proposals.

Predictive inventory is especially beneficial with fresh produce, where the inventory data is typically the poorest. As the transaction data starts to deviate, predictive inventory identifies anomalies and recommends inventory checks to correct potential issues. As a result, store personnel no longer need to spend time on daily inventory checks but can take cues from the system’s recommendations. Further, as it continues to take in and process data from transactions and store personnel, a machine learning-enabled system will become more accurate and make better recommendations over time.

Retailers without a successful balance maintenance plan will benefit enormously from introducing predictive inventory that continuously learns from what their personnel see and do in stores. With balance maintenance effectively automated, the system now has a highly accurate starting point to generate intelligent order recommendations.

READ MORE: Q&A: How to tackle phantom inventory pains with predictive technology

3.2 Batch-specific spoilage projections alert stores to variations within the same product

For fresh products, such as produce, different batches will have different spoilage dates, meaning that SKUs of the same product can vary significantly in freshness. An advanced solution with batch-specific spoilage optimization automatically considers the expiration dates of individual batches of an SKU to project spoilage accurately.

Even though warehouses and DCs have reliable batch balance information, visibility into that data isn’t generally available at the store level. That lack of visibility means retailers operating under a decentralized model cannot accurately project when individual batches will spoil in their stores.

However, a solution capable of batch balance tracking can automatically create batch balances from store deliveries, enabling store personnel to track them accurately. Once the system knows which batches make up a store’s inventory, it can start calculating batch-specific spoilage projections to order against — ultimately ensuring high availability for top-quality fresh products.

Unfortunately, point-of-sale (POS) systems usually don’t provide insight into the batch from which a customer buys. Shoppers typically don’t reach for SKUs from older batches, preferring the freshest items available—a consumer behavior that can create a great deal of inaccuracy if not accounted for.

That’s why a modern planning system needs first-in-first-out (FIFO) rate estimation capabilities that estimate which batches customers have been shopping from based on historical behavior. The system uses this information to accurately pinpoint the actual store inventory balance and further improve spoilage projections.

A first-in-first-out (FIFO) approach to inventory management ensures the oldest items with the shortest remaining shelf life are the first sold, driving a range of benefits, including:

- Reduced risk of spoilage, waste, and financial loss.

- Streamlined inventory management and more accurate inventory levels.

- Reduces the risk of over- or understocking.

- The highest quality of fresh products for customers.

3.3 Adaptive safety stock optimization balances the risks of stockouts against waste

Forecast accuracy alone isn’t enough to balance the risk of waste against the risk of stockouts. One of the most effective steps to reduce fresh spoilage while maintaining availability is optimizing safety stock, creating a buffer against demand uncertainty. Safety stock may not be the trendiest topic, but getting it right is a critical enabler for the best possible order recommendations and resulting improvements to availability and waste metrics.

If left unadjusted throughout the week, safety stock levels that guarantee availability on Saturday when everyone’s out for their weekly “big shop” also guarantee spoilage on Monday once shoppers are back to work. That’s why fresh retailers need a system that dynamically adjusts safety stock levels to correspond to expected sales volumes across each weekday’s profile.

Traditionally, safety stocks look backwards, using historical demand patterns, lead times, and desired service levels to determine how much additional inventory is needed to cover demand and lead time variability. A modern solution increases accuracy by basing safety stock calculations for highly reactive fresh products on future demand rather than historical data.

New product introductions, seasonal or holiday periods, and promotions are a few examples of demand drivers that require the accuracy of a forward-looking approach to safety stock levels that ensures availability no matter what variation. A reactive, accurate system that automatically adjusts fresh safety stock to match future demand can enormously impact spoilage and availability metrics, especially for seasonal management.

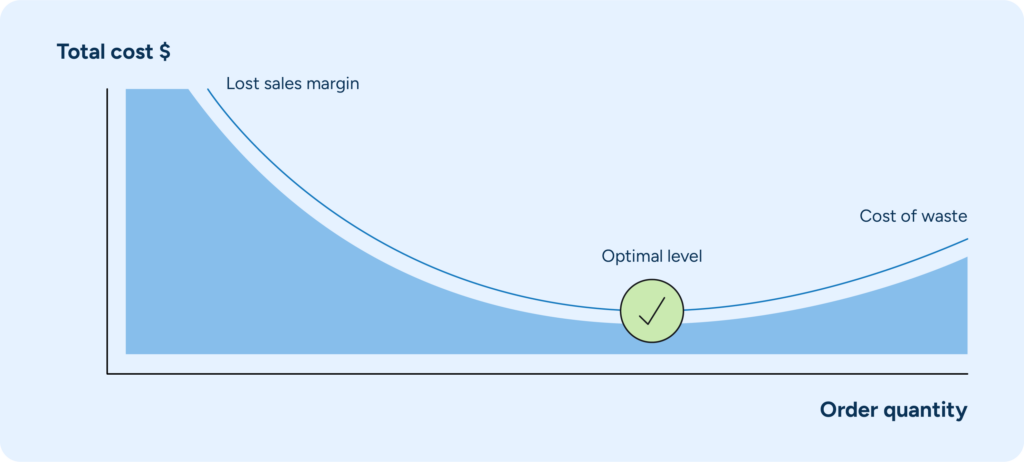

It’s important to note that this process also accomplishes a very complex cost optimization. The system estimates the probabilities of spoilage and lost sales for every order placed at every store and calculates the optimal sweet spot to minimize the total cost for every order instance.

The key benefits of this type of fresh safety stock optimization include:

- Increased availability and minimized cost of lost sales.

- Reduced spoilage and inventory costs.

- Timely safety stock adjustments to seasonal and other demand variations.

- Improved accuracy and relevance of future projections.

3.4 Production management: Make-to-sell and break-to-sell drive next-level complexity

For many retailers, fresh goes beyond the aisles and produce bins. Convenience plays an increasing role in consumer decision-making, driving considerable growth in retailers offering ready-to-eat meals, sandwiches, baked goods, and more. As a result, on-site production has become critical to many food retailers’ profitability.

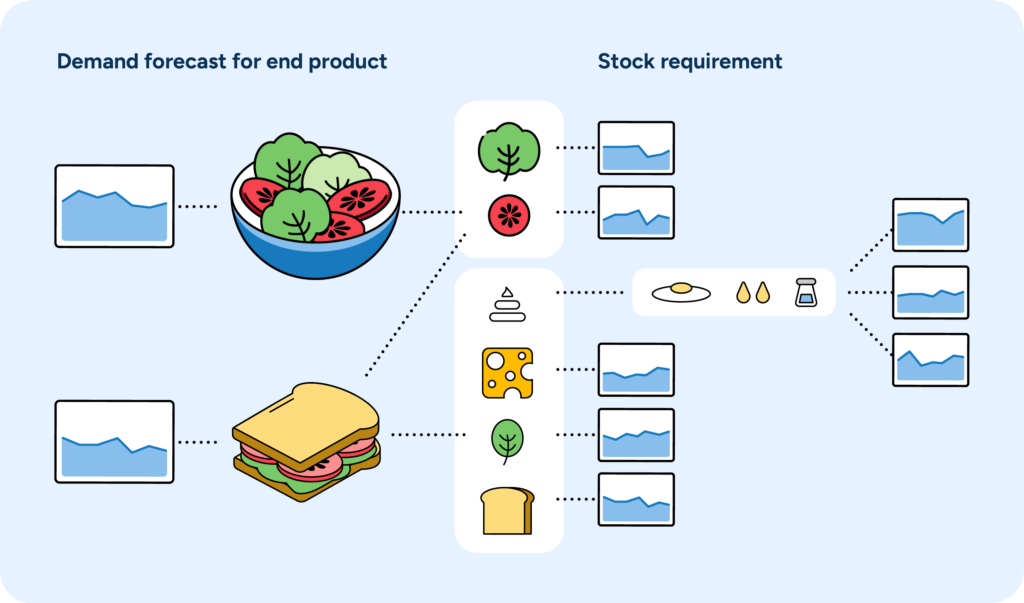

Retailers who produce fresh items in-house must be able to break demand for those products down into the ingredients used to manufacture those end products. An effective planning system must manage the separation of “sellables” and “orderables” — accurately mapping forecasts to end products and components. This additional layer of forecasting ensures stores have everything needed to create a sellable product consisting of multiple items ordered individually.

Sometimes, the end product calls for ingredients within components — such as dressings or sauces produced on-site — necessitating similar calculations for all recipe components. At scale, that level of multi-layer analysis would be impossible for any human but easily managed by a modern, optimized replenishment system.

4. Stores play a critical role in fresh success for all replenishment planning approaches

No matter where on the operational scale a retailer falls, their goals – maximizing sales and customer experience while minimizing waste – are the same. Because fresh products are especially time-sensitive and often subject to localized demand patterns, stores’ influence on ordering and ability to efficiently manage inventory flows are essential to reducing costs and stress and enabling a high-quality experience for shoppers.

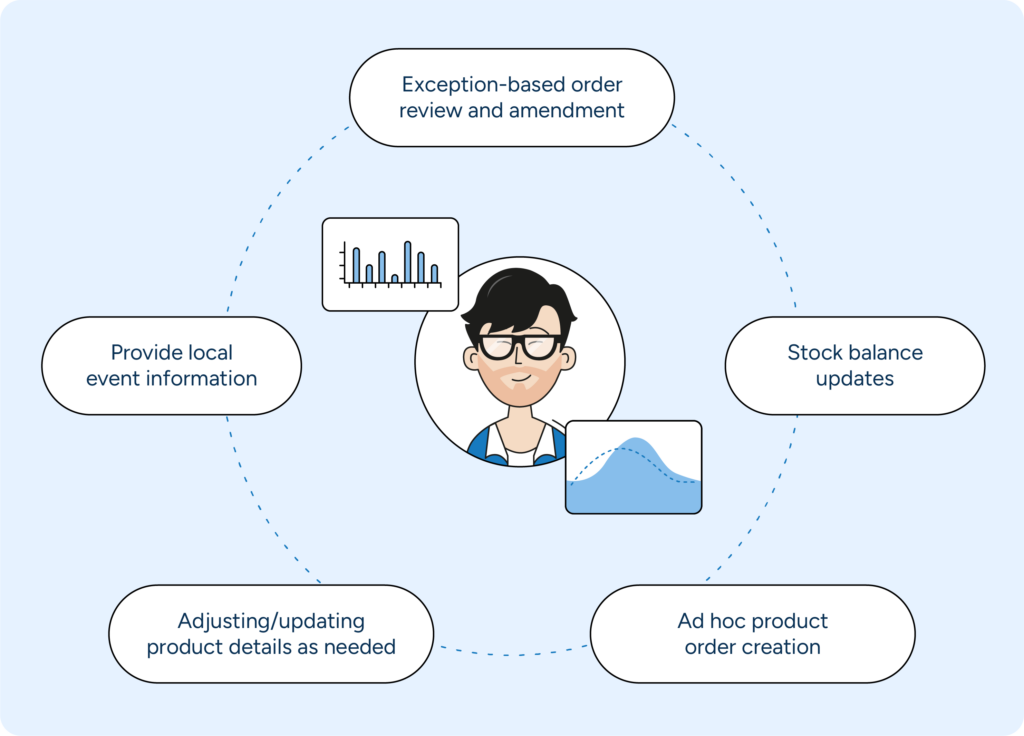

There are several essential capabilities that a modern solution should include to empower store personnel to drive replenishment success:

- Order review, amendment, and ad hoc creation – Store employees are on the front line and have direct insights into meeting the needs of local customers. Enabling them to review and recommend changes and create orders based on specific, local demand ensures customers get the products they want when they want them.

- End-to-end communication and visibility – Unifying central demand planning and field store execution in a single planning tool is the best way to improve fresh quality and availability while balancing the risk of over- and understocking.

- Inventory updating and reporting – A modern system that can leverage store employees’ insights and reporting on on-hand stock levels enables inventory balancing and alerts for issues such as recalls. Dashboards for KPIs like sales metrics help drive order recommendations to meet local demand shifts.

- User-friendly interface for fast and easy adoption and use – Today’s labor shortages and workforce retention issues make it necessary for retailers to equip store associates with tools that are not only powerful but user-friendly and fast. Lost time or low adoption due to extended training needs or overly complex interfaces reduce efficiency and increase costs.

RELEX’s Tim Kirsch shares insights into the essentials of empowering store associates to drive efficiency. Watch the full webinar for the whole story.

4.1 Visibility between stores and central demand planners is essential for efficient collaboration

Retailers frequently struggle to balance just-right inventory, timely replenishment, and low spoilage rates. Fast-moving fresh products are too unpredictable to find success without all parties moving in lockstep toward shared goals. The greatest challenge for retailers, especially those on the decentralized end of the scale, is a lack of visibility, collaboration, and alignment between central demand planners and the frontline teams who place store orders.

Central planners need store-level insights into the most recent on-shelf availability and fresh spoilage metrics to continuously optimize demand projections for accuracy. The fresher the store-level data, the more accurate demand planners can be with each store’s future demand, taking a variety of factors into account, including seasonality, local buying behaviors, and more.

And the more detailed the data, the better the in-store experience is for shoppers. Further, an automated, exception-based order review and amendment process prevents store and department managers from spending hours on manual ordering, enabling them to focus on more value-creating customer experience work.

4.2 Efficiency in stores can only improve with the right tools and functionality

Because store personnel play such a vital role in fresh replenishment, it’s essential to equip them with a solution that enables location-specific item and inventory visibility, ordering, and audits. When store personnel have the tools to be successful, once-dreaded daily tasks are easily managed, and local teams can remain nimble to ensure their customers receive optimal service levels and access to the freshest foods possible.

A robust mobile store execution tool can gather those insights by enabling two-way communication and providing store personnel access to the inventory planning software via mobile phone or tablet.

Ensuring the right products are in the right stores at the right time is a primary goal for all retailers. However, ordering, receiving, and stocking those products directly impacts staffing needs. If retailers understaff their stores, customer service suffers, and employees can become overwhelmed, leading to stress. On the other hand, overstaffing drives unnecessary labor costs, increasing a retailer’s most significant expense.

Retailers must leverage modern tools that connect supply chain and workforce planning communication and collaboration, ensuring staffing directly aligns with ordering and delivery needs.

4.3 Capacity optimization helps de-stress stores and customers

Retailers are all too familiar with the fact that weekends see higher footfall as shoppers come in for their weekly “big shop.” At the same time, perishable products require frequent deliveries. For larger retailers, the flow of goods is heavy enough to call for daily or even intraday deliveries from their distribution centers. The resulting high volume of activity in the store’s front and back simultaneously can become chaotic and stressful for staff and customers alike.

While fresh categories are the core of this guide, it’s important to keep in mind that issues arising with one or two categories in the store – especially during peak times – can have a ripple effect, impacting all categories. Retailers need a planning tool flexible enough to support the entire assortment and the store’s ability to manage all of them efficiently.

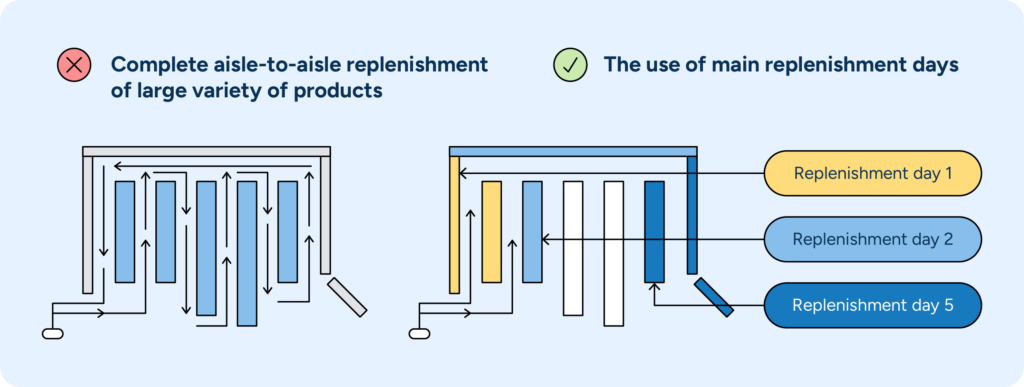

For example, a tool using main replenishment days uses store-level data to ensure items shelved near each other get replenished simultaneously. The result is more efficient in-store stocking in one area of the store that doesn’t require personnel to waste time moving roll cages across the length of the store, preventing them from focusing on customer service and disrupting the shopping experience.

By pulling main replenishment days for center-store products forward in the week to lower-traffic days, retailers can balance inventory flows for the entire store, making life much easier for overwhelmed store personnel on busy weekends.

5. Visibility into broader processes supports long-term planning optimization

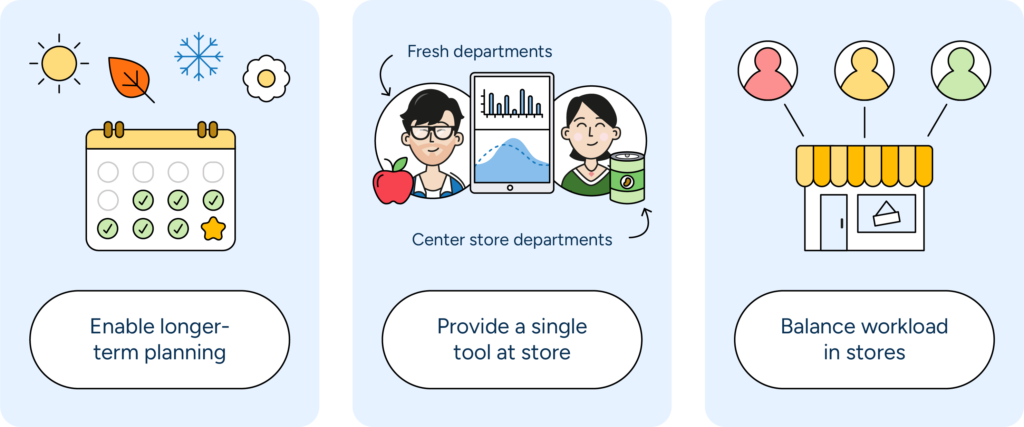

There is no doubt that fresh management depends on efficient store operations, order accuracy, and forecast granularity. However, when considering solutions to achieve these goals, retailers must maintain a clear view of the business’s long-term goals. Acknowledging that fresh store replenishment is one part of a much larger picture enables grocers to focus not only on getting today’s order as accurate as possible but also on securing a tool that allows holistic planning and optimization across the entire value chain.

A single system for all products enables grocers to manage replenishment needs from center store to deli to fresh produce to packaged meats from end to end with complete visibility. The system must also be user-friendly, easy, and fast for associates and management to adopt. A mobile-enabled solution also increases efficiency for in-store associates who can submit insights and order recommendations on the spot to help inform broader supply chain decisions. Further, a solution that provides configurability allows the business to create rules that address their unique goals and processes without relying on costly coding and technical support.

Long- and short-term planning in a solution that covers the entire portfolio is beneficial when looking at all elements together to improve planning, especially around pivotal seasons and holidays. A good system provides visibility into demand and inventory weeks and months in advance. This equips planners with the insights needed to plan proactively for big seasons and holidays, preventing the capacity constraints and supply chain bottlenecks that frequently plague grocers during their busiest seasons.

Multi-echelon coverage looks at the complete end-to-end supply chain, not just from the perspective of an individual store’s success, driving significant benefits through a more holistic view. An integrated supply chain enables efficient inventory management at a high level of automation. Having all data on demand forecasts, available stock, delivery schedules, lead times, and batch sizes for all supply chain echelons available in one planning system, retailers can seamlessly optimize inventory flows throughout the supply chain.

6. The bottom line: Fresh replenishment is all about balance

There seems to be a common myth in fresh retail that to optimize one section of processes, another must suffer. For example, retailers might think that maintaining a robust assortment comes at the cost of risking spoilage or margins. Contrary to this traditional belief, though, the goals of reducing waste and maintaining high availability aren’t mutually exclusive — because the problems share a root cause.

The key to achieving success in the complex world of fresh retail lies in striking that perfect balance between efficiency, accuracy, and adaptability. By leveraging advanced AI-driven forecasting and replenishment tools, grocery retailers can optimize their supply chain, minimize waste, and maintain high availability of fresh products. This balance not only benefits the environment but also significantly impacts the bottom line, as wasted food costs roughly twice the amount of retail sales profit.

By embracing technology solutions that enable these essential functionalities, retailers can improve store efficiency, order accuracy, and forecast granularity. A single system for all products, long and short-term planning, and multi-echelon coverage provide a holistic view of the entire value chain, driving significant benefits through a more integrated and collaborative supply chain.

And not only is holistic balance in the fresh supply chain possible, but it has been proven.

Fresh retailers have been able to see results such as:

- 10-40% typical reduction in spoilage

- +6% fresh sales from availability improvements

- Automation and error elimination in ordering

Ultimately, maintaining that balance is crucial in navigating the challenges and complexities of fresh retail and technology, and it is here to ensure this precarious act is possible. By implementing advanced planning tools and best practices, grocery retailers can achieve a harmonious balance between waste reduction, high availability, and profitability. This balance contributes to a more sustainable future and ensures a better customer shopping experience and a more efficient and profitable operation for retailers.