How to optimize cycle counting and banish phantom inventory

Feb 12, 2025 • 11 min

Poor inventory data is the perennial curse of retail planning. Stockouts slip by unnoticed because inaccurate data records show greater product availability than exists in reality. This phantom inventory lulls retailers into a false sense of security, convincing them that they’ve got plenty of stock to meet demand while all the while obscuring empty shelves and lost sales.

Many retailers try to circumvent this issue with inventory cycle counting, an inventory auditing approach that involves counting different product segments at different times.

However, traditional cycle counting strategies lack the data and technology to make them truly accurate, leading to arbitrary schedules and poorly targeted impromptu inventory checks.

Some retailers try to compensate by increasing the frequency of counts, but this approach drains time and resources many stores don’t have while putting customer service second to inventory planning and management. Other retailers simply stick to standard counting schedules that may or may not reflect product behaviors and hope that store personnel – or worse, customers – spot gaps and items that need correcting.

With bottom lines and customer loyalty at stake, businesses need to optimize their cycle counts with AI-driven predictive technology and unified solutions that bridge the gap between different planning functions and execution teams.

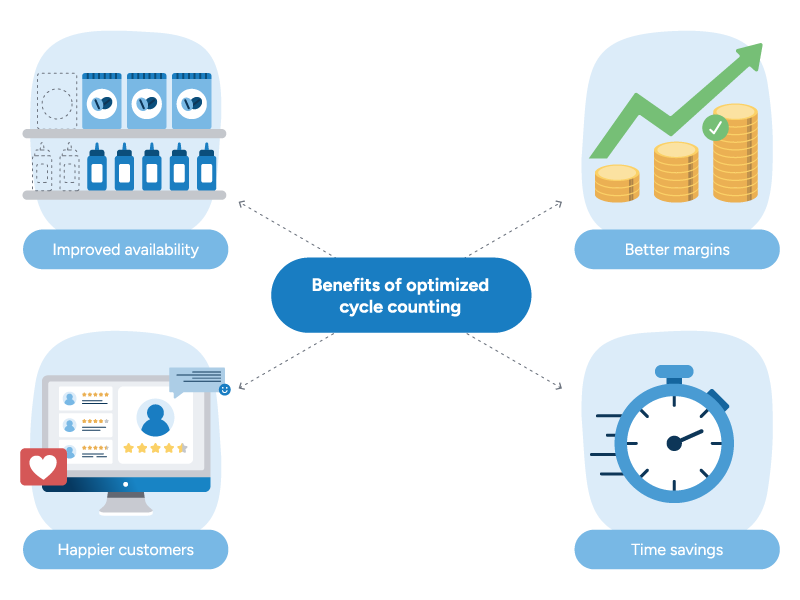

By getting cycle counts right, retailers boost data accuracy with minimal effort, ensure availability, and lay phantom inventory to rest.

1. What is inventory cycle counting?

Cycle counting is a divide-and-conquer approach to inventory audits that separates products into manageable segments and staggers the frequency and timing of each segment count. When optimized, this rotating approach:

- Increases operational efficiency by minimizing the amount of time spent counting.

- Makes the best use of that time by maximizing availability for products that will make a material difference to customers and margins.

Note: When it comes to inventory counts, there is an important distinction to make. Every company must complete at least one full inventory count every year for financial purposes. While these yearly counts help with audits and fiscal tasks, they do not support supply chain and retail planning throughout the year.

2. The components of optimized cycle counting

Optimized cycle counting involves two different types of inventory counts: anomaly-driven and scheduled.

Anomaly-driven counts

Some inventory solutions have rudimentary anomaly detection mechanisms in place. But modern retail challenges call for sophisticated AI-powered solutions that reliably sift through the masses of data, looking for incongruity.

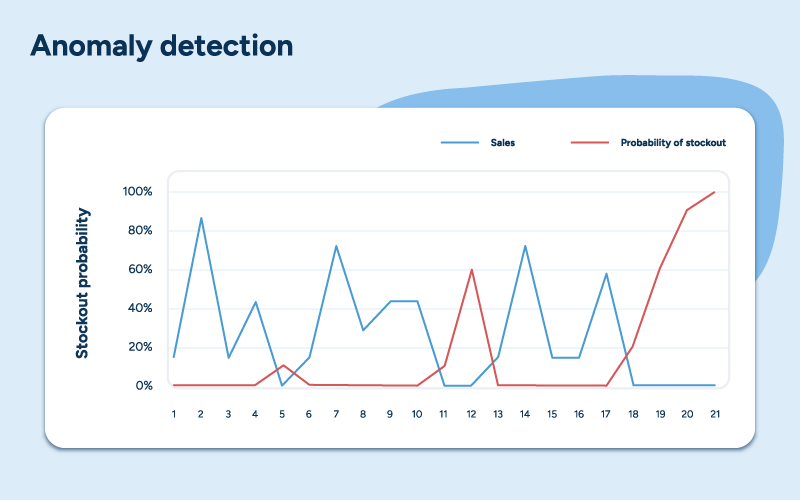

These systems can, for instance, identify discrepancies between inventory records and corresponding sales numbers to determine the probability of a stockout. They then direct store employees to check items with the highest stockout probability so they can fix potential issues before they worsen.

More advanced solutions can further reduce the need for manual checks by self-correcting the record once it has reached a certain probability threshold.

These impromptu checks safeguard availability and freshness while eliminating or reducing the risk of lost sales.

Optimized schedules

The second part of optimized counting involves improving the schedules themselves, something that very few solutions on the market offer.

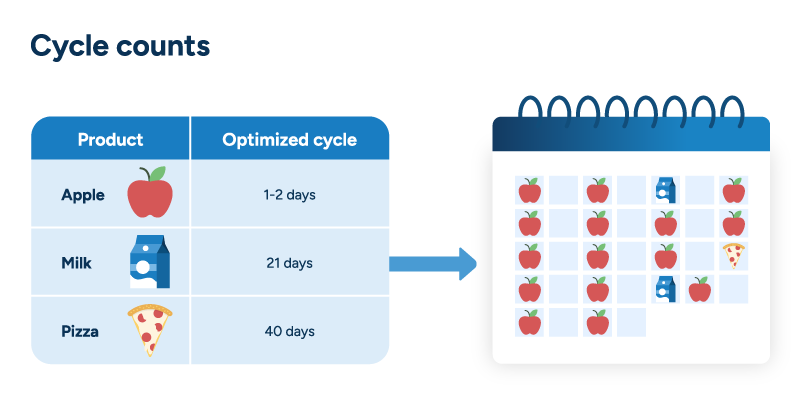

Most retailers use standard schedules for counting different segments or store aisles. A grocer may count center-store products every four weeks but will check fresh and fast-moving products more often to ensure that popular and perishable items are always in stock.

Planning systems that easily integrate data management and machine learning (ML) help retailers assess and improve those schedules. These systems employ heavy-duty computational capabilities that use historical inventory accuracy, demand levels, and ordering parameters to calculate stockout probabilities.

Those probabilities alone, however, are not the whole story. The key to optimizing schedules is linking those probabilities to business goals.

An optimized scheduling solution pinpoints when stockouts will negatively and seriously impact KPIs and uses that information to refine count frequencies.

For instance, a center store product may experience low demand relative to its batch size, which means that small discrepancies in inventory do not immediately cause errors in ordering. The item can be counted less frequently with minimal risk.

On the other hand, a shelf with a popular fast-moving item may usually look full as store employees pass it during their shifts. In reality, that shelf is empty for at least one hour at the end of every day, perhaps when people are picking up dinner on their way home from work. The retailer is losing sales, and without data-backed optimization, they might not realize it.

By optimizing the underlying cadence that dictates the majority of inventory counts, retailers can significantly elevate order accuracy with minimal heavy lifting to reduce lost sales.

3. The role of cycle counting in combating phantom inventory

Phantom inventory is the phenomenon that occurs when inaccurate inventory records report more available stock than exists on shelves. These ghost records stem from receiving errors, theft, product misplacement, or mistakes such as scanning the wrong item or weight.

Up to 60% of retailers’ inventory records may be inaccurate, and the costs of poor inventory data aren’t pretty. Up to $400 billion in retail revenue is lost due to incorrect store stock.

Learn more: Solving retail’s $400 billion accuracy problem

Let’s say you count a specific product once every four months. What happens if the inventory records for that product become skewed? Your records say the item has plenty of stock, but in reality, sales have plummeted due to a lack of availability.

Depending on where you are in your schedule, it could take you months to realize that something has gone wrong. Meanwhile, you are disappointing your customers and losing sales. The faster-moving or more popular an item is, the more immediate and severe the impact of the problem becomes.

What happens if you apply optimized cycle counting to this scenario?

- Anomaly detection recognizes the item’s significant sales drop and alerts store personnel to the possible stockout so they can correct the issue as soon as possible.

- Optimized scheduling plays a preventive role, recommending that the item be counted every three months instead of every four. This schedule adjustment mitigates the chance of an exponential and recurring pile-up of issues over time.

While in this example, the scheduled count frequency increases, applying optimization across schedules should reduce the overall hours and work required for inventory management. Store associates would count the right products at the right time, minimizing the time and labor involved to ensure accurate data and stocked shelves.

By eliminating the data inaccuracies that cause phantom inventory, optimized cycle counting helps retailers cash in on the serious potential to improve availability, customer service, and margins.

The flip side: The same technologies that mitigate phantom inventory address the opposite problem – records showing less inventory than is available. Optimized cycle counting helps retailers correct this, reducing excess inventory, waste, and spoilage.

4. Best practices for achieving optimized cycle counting

Cycle counting shouldn’t be left to best guesses and intuition. The right solution and the right strategy will help retailers refine and make the most of their data so they can improve processes, ease change management, and start reaping benefits sooner.

Invest in predictive technology

Predictive inventory solutions use machine learning (ML) to estimate and correct inventory data. They optimize cycle counts and then combine the data gathered by anomaly checks and counting schedules with AI-driven inventory management capabilities that learn patterns across items, stores, and similarly shopped categories over time. In this way, predictive models automatically close the gap between ERP data and real-world inventory levels.

These solutions employ:

- Automatic monitoring that tracks inventory metrics like hit rates, compliance, and response times and helps retailers better control inventory and ensure availability.

- Advanced mathematical modeling that goes far beyond simple heuristics, combining huge data inputs like demand levels, replenishment parameters, and historical inventory fluctuations to predict trends and optimize count cadences.

- Adaptable ML systems that use counting data and historical patterns to automatically model inventory drift, improving order accuracy with less manual work and helping retailers react to market shifts quickly.

Unify processes

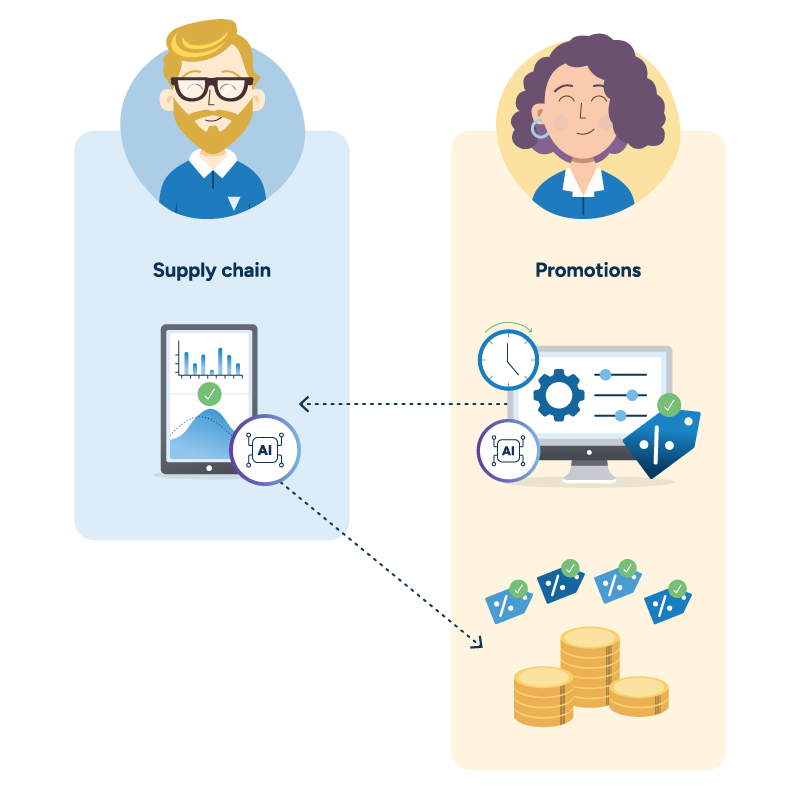

Cycle counts should be integrated into an overall unified platform, making it easy for different planning functions to share data and adjust plans.

All functions—from forecasting and replenishment to assortment planning to promotions—should dip into the same data lake and transmit plans and calculations across the organization. Data accuracy and visibility ensure that one team’s decisions will not upset another’s delicately balanced plans.

Store-level execution

End-to-end planning has to include the store execution level.

For instance, say you have this beautifully optimized schedule and time-sensitive alerts. How will you easily and at the right time get these into the hands of store employees? Once you do, how do you incorporate store-level insights to improve those schedules and alerts? How do you monitor overall performance and redirect plans as objectives change?

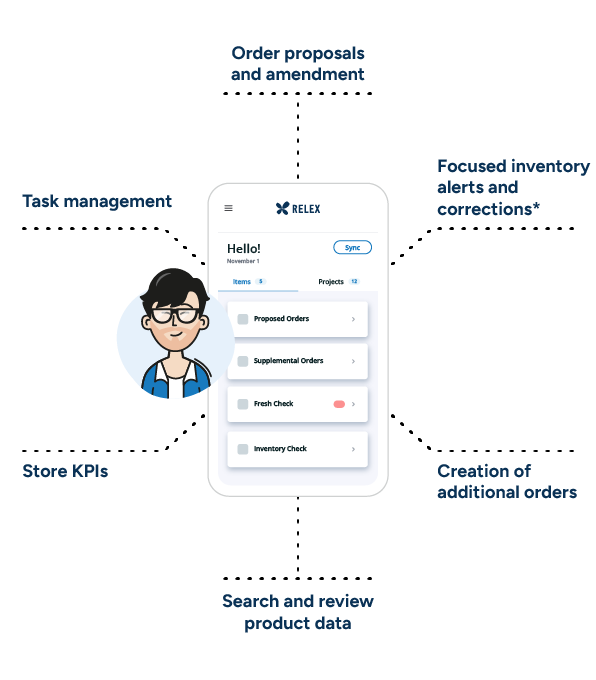

Enter solutions like RELEX Mobile Pro, an in-store execution app that streamlines store-level tasks and improves replenishment.

Mobile Pro takes the optimized schedules and anomaly alerts calculated on the back end of the planning process and delivers targeted, prioritized count recommendations to store associates. Employees correct balances in the same app, ensuring timely and accurate inventory checks and providing store-level feedback to the planning teams, closing the loop all within one application.

This exchange of information between planning and execution teams helps retailers refine replenishment calculations and reduce spoilage and stockouts while increasing sales.

Learn more about RELEX Mobile Pro.

Ramp up over time

When implementing a solution, companies can gradually introduce technical advancements to alleviate change management friction while still securing ROI.

Companies with no inventory counting solution usually perform regular and extensive inventory audits. These counts are either unnecessary or ineffective, leaving inventory gaps unnoticed and unfilled for prolonged periods.

To lessen the strain on resources caused by inefficient cycle counts, companies should first focus on implementing automation that recommends targeted manual counts. An optimized solution prioritizes lists of items to check, and alerts store employees to anomalies so they don’t waste time checking the wrong products.

Over time, two things will happen.

- The ML-based solution will learn more and more about inventory behaviors, creating more accurate data records and recommendations for more profitable and efficient planning.

- Store personnel will see for themselves the accuracy achieved by recommended cycles and learn to trust the system, easing and ensuring adoption.

Companies can then graduate to greater automation that corrects high-priority inventory anomalies without manual checks. Automation saves significant time and effort while improving inventory management and order accuracy.

5. How retailers have expelled the ghosts of phantom inventory with RELEX True Inventory

RELEX True Inventory is a predictive inventory solution that uses advanced probabilistic modeling and machine learning to optimize cycle counting, enhance data accuracy, and improve store efficiency.

It addresses phantom inventory and improves replenishment by pulling in the same granular data used by RELEX Forecasting & Replenishment for precise calculations.

Thanks to the RELEX unified solution, True Inventory can inform and align with broader planning functions, allowing teams to track, monitor, and improve KPIs like sales and freshness – all on one platform.

Take, for instance, Ametller Origen, Catalonia’s leading regional provider of fresh food and quality processed products. Stockouts and labor-intensive inventory counts hampered the company. They wanted to increase automation and enable centralized store ordering through better inventory balance control.

“Stock is the one factor we didn’t manage directly within our supply chain consistently,” said Jose Ramon Franco, Supply Chain Manager at Ametller Origen. “True Inventory is a valuable tool which helps us reduce deviations and phantom stocks, allowing for orders that better match actual store demand.”

The solution helped the company reduce errors by 27%, achieving a significant sales lift and improving availability without impacting spoilage.

“True Inventory is a valuable tool which helps us reduce deviations and phantom stocks, allowing for orders that better match actual store demand.”

Bünting, a family-owned food wholesaler and retailer in Germany, strictly used manual processes to manage store replenishment and fresh produce orders. Inventory counting was based on fixed cycles for the entire assortment to the detriment of freshness.

True Inventory enhanced balance quality, shifting store tasks from day-to-day manual ordering decisions to exception-based inventory counting. Store personnel with local knowledge and insight could focus on reviewing and amending order proposals for presentation stock and exceptional items and events.

The company moved from local fruit and vegetable replenishment decision-making to a centralized model, saving significant time in the F&V department’s daily routines.

The implementation of True Inventory resulted in a 2% increase in sales value, a 43% reduction in balance errors, and a 1.6% improvement in product availability.

6. How predictive technology keeps cycle counting ten steps ahead of data issues

While traditional cycle counting methods cannot deliver the data accuracy and planning flexibility modern retail requires, advanced planning solutions now offer the capabilities to optimize cycle counts and mitigate phantom inventory.

With AI-based predictive inventory solutions and unified processes, retailers can keep shelves stocked, records updated, and customers happy.

7. Cycle counting FAQ

How frequently should cycle counts be performed?

Cycle counts should be scheduled according to the needs of each product, product segment, or location. Schedules should account for historical inventory counts, demand levels, and replenishment parameters for each item, as well as available time and labor.

What are some traditional cycle counting methods?

Here are some of the retail industry’s most common cycle counting methods.

- Process control group cycle counting: Focuses on counting items prone to errors due to process issues, such as receiving or shipping.

- ABC analysis: Categorizes items and prioritizes counting based on value and turnover rate.

- Random sampling: Involves counting a random selection of items to get a snapshot of inventory accuracy.

- Control group cycle counting: Counting a specific group of items repeatedly over a short period to identify and correct systemic issues.

How can retailers optimize their cycle counting?

Retailers can optimize cycle counts by implementing anomaly-driven alerts and refining the cadence of regularly scheduled inventory checks.

Mathematical models and machine learning capabilities can analyze historical inventory data for patterns and discrepancies, assess demand levels, and account for order parameters like batch size to calculate stockout probabilities and their potential impacts on KPIs.

Optimal cycle counts help retailers maintain accurate inventory balances, improving replenishment through reduced stockout and overstock situations.