“Right product, right quantity, right place, right time.”

It’s an adage that most swear by in supply chain planning, and for good reason. Efficiency and accuracy in inventory planning and management are the crux of profitability for wholesalers and retailers alike.

It’s a great maxim — but it isn’t quite enough for many companies. Everything from internal promotions to supply constraints to social media trends can shift consumer demand out of the blue. Certain businesses built to operate solely on a “right place, right time” inventory planning method can easily find themselves underprepared to face sudden volatility. At the very least, they’ll likely need to move stock around at the last minute, creating high-cost peaks in volume and workload.

Threading the needle between “too much stock on hand” and “not enough stock on hand” was hard in the past, and it’s even more difficult now to accomplish without an optimized process. Wholesalers and retailers looking to cut costs must seriously consider ways to improve their current approach — a prospect made simpler through the investment in a robust supply chain planning tool.

With the right inventory planning software, businesses can better plan their inventory — and achieve higher profitability — than ever before.

Key takeaways

- An optimized inventory planning process is essential for managing stock levels and proactively ensuring smooth operations.

- The benefits of inventory planning include improved cost savings, enhanced customer satisfaction, and a better utilization of capacity and resources.

- Volatile supply and demand, shifting internal and trading partner plans, and inefficiencies on the store floor all threaten to derail optimization efforts.

- Companies should work to increase demand forecast accuracy, improve data management processes, enhance internal and external communications, and develop effective capacity utilization strategies to improve planning processes.

- The right AI-powered software is essential for maximizing the effectiveness of inventory planning.

What is inventory planning?

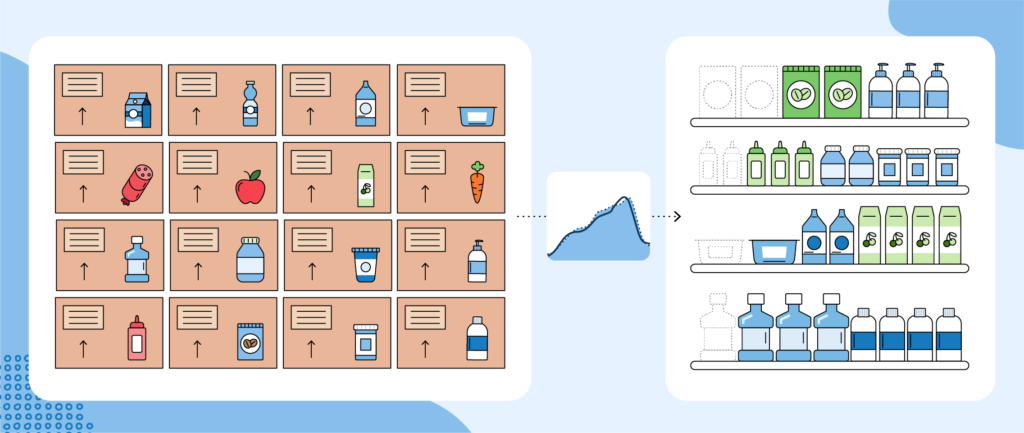

Inventory planning is the process of determining the correct volume of products to order for a company to meet its expected sales figures. In a traditional manual process, an inventory planner identifies how much stock was sold over a given period and runs those figures against how much the business expects to sell in the immediate future. The planner then identifies the optimal time for the product to arrive at the store to minimize holding time and costs.

In an optimized supply chain, a company uses the available capacity on shelves, in transportation, and of personnel in the most cost-efficient manner. Products flow seamlessly from suppliers to a retailer’s storage room and on to paying customers.

The inventory planners’ role is to ensure this flow remains uninterrupted and stable to maximize profitability. Planners must react quickly to identify demand surges and ensure product availability. But when demand wanes, planners must reduce the product flow to minimize the risk and cost of carrying excess inventory.

Inventory planning may sound simple in theory. In practice, supply and demand volatility, general supply chain inefficiencies, phantom inventory, and sudden strategy shifts throw endless wrenches into the process. Inventory planners must strike the tricky balance of ordering the correct amounts of products to meet customer demand despite these challenges — without over- or under-ordering.

Retail and wholesale vs. consumer goods and manufacturing inventory planning

It’s important to understand how different positions in the supply chain affect inventory planning approaches. Manufacturers, retailers, and wholesalers share many of the same fundamental challenges, but acknowledging their key operational differences helps contextualize how each sector applies inventory planning principles.

- Production vs. storage capacity. Retailers and wholesalers must thread the needle between excess stock and stockouts within their available storage space. Manufacturers face this same balancing act but with added production planning complexities that amplify the impact of demand volatility. These complexities include managing raw materials, optimizing batch sizes, and navigating production line constraints.

- Supply chain complexity. Retailers typically manage shorter, more frequent replenishment cycles, whereas manufacturers often coordinate extended international supply networks. This positioning difference means that when disruptions occur — whether from social media trends, material shortages, or economic shifts — manufacturers need longer lead times to adjust their operations accordingly.

- Automation requirements. Modern retail operations require sophisticated systems to handle promotion planning, store-level replenishment, and sudden demand shifts. Manufacturing automation must address these same challenges while simultaneously orchestrating production schedules, material requirements, and finished goods inventory. This dual need makes their planning systems incredibly complex while still factoring in many of the same fundamental principles as their retail counterparts.

The fundamental challenges of supply chain planning — demand volatility, resource optimization, and operational efficiency — unite all sectors, even as their operational differences shape specific approaches to inventory planning. Understanding these challenges — and solutions like optimizing safety stock quantities, replenishment frequencies, and stock levels across the network — reveals why effective inventory planning has become essential for modern business success.

Benefits of inventory planning optimization

Every wholesale and retail business requires inventory planning to keep the lights on and the wheels spinning. This makes it a perfect process for forward-thinking companies to optimize to gain an advantage over competitors still reliant on manual processes and dated technology. Competitors aside, the extensive cost benefits of a streamlined planning process justify any initial investment in process optimization.

These revenue-boosting benefits include:

Increased cost savings

It pays to find the sweet spot in forecasting and replenishment. An optimized planning process reduces inventory costs and improves cash flow through improved inventory turnover.

Meanwhile, businesses pay a hefty price for misreading consumer demand. Order too much, and you pay out the nose in carrying costs and spoilage. Order too little, and you lose sales to costly stockouts.

Improved customer satisfaction

It takes a long time to build customer loyalty, but it only takes a few stockouts to lose it. Customers expect to find what they need every time they go to a store, and an optimized inventory planning process helps to meet their product availability and general experience expectations. Optimization also helps companies maintain quality and freshness in the case of perishables.

Better utilization of resources

Inventory flows continuously in an optimized supply chain, but it does so through a finite physical pipeline of warehouses, DCs, storerooms, and shelves. Strategic planning allows companies to order in-demand products at the optimal time to use their storage space and transportation fleet more efficiently. Placing smarter, more intentional orders will also allow businesses to better schedule their workforce for deliveries and replenishment.

3 biggest inventory planning challenges

When evaluating inventory planners’ challenges, the ol’ “right product, right quantity, right place, right time” rule of thumb falls apart. The saying has always been overly simplistic, especially for wholesalers and retailers managing tens of thousands of SKUs from dozens of suppliers. The approach’s limitations are especially evident in the post-COVID supply chain, where supply disruptions and demand volatility alter inventory needs and availability daily.

Planners face the Herculean task of concurrently managing numerous inventory challenges, including:

Volatile supply and demand

Inventory planners face uncertainty around the timely arrival of their ordered products and whether customers will buy them. On the supply side, inventory planning is hampered by:

- Material shortages.

- Supply chain disruptions.

- Limited collaboration with suppliers.

- Purchasing and transportation conditions geared to maximize volumes

And it’s not as if gauging consumer demand is any easier. Companies reliant on manual forecasting or antiquated supply chain planning platforms will find it hard to react nimbly to sudden demand shifts caused by:

- Social media trends.

- Economic sentiment.

- Weather events.

- Seasonality.

- External factors, like local sports events or concerts.

- Internal factors, like promotion plans or assortment changes.

An inventory imbalance caused by a supply disruption hurts, as does one caused by unexpected demand changes. With the current state of the supply chain, it’s not uncommon for businesses to simultaneously experience both issues at significant costs.

Excess inventory levels and limited capacity utilization

Companies often lack visibility into the entire supply chain, causing them to overreact to sudden demand shifts and over-order certain products. This over-ordering leads to excess inventory levels, forcing businesses to hold onto stock that doesn’t move quickly. Whereas safety stock levels and proactive material flow balancing protect businesses from costly stockouts and capacity problems, excess inventory is often a problem that serves no functional purpose.

Most businesses find that inventory holding costs total somewhere between 15-30% of the value of the inventory itself, depending on the costs assigned to inventory carrying. These units take up space that could otherwise be used by SKUs that customers actually buy. Excess inventory levels can also result in spoilage and waste for businesses dealing with fresh and quick-to-expire products, further cutting profit margins.

Costly store floor inefficiencies

Products don’t put themselves on store shelves. Companies so often focus on the cost of transporting and storing inventory itself that they forget to address time- and money-consuming workforce planning inefficiencies.

Specifically, businesses often find it difficult to schedule the right number of employees to coincide with deliveries. This proves especially complicated when stores haven’t optimized their forecasting and replenishment, resulting in:

- A high number of deliveries from disparate product categories housed in different parts of the store.

- A high concentration of deliveries at the end of the week, causing capacity constraints.

- Poorly timed deliveries occurring during high-traffic or low-staffed periods.

Any combination of these three issues leads to increased workloads for employees or costly overtime for the company. But these concerns also negatively affect customer sentiment. Staff that field deliveries and replenish products during peak times can’t give customers the attention they deserve. And the consumer experience diminishes when employees abandon carts in aisles to assist customers in need.

4 strategies for effective inventory planning

Inventory planners manage many moving parts just to keep inventory flowing, so making fundamental changes to their processes can seem daunting initially. However, the long-term cost benefits of optimizing planning processes justify initial investments in ironing out planning inefficiencies.

Retailers and wholesalers should focus on these key strategies to maximize the efficiency of their inventory planning efforts:

Increase demand forecasting accuracy

Demand forecasting forms the core of any business’s planning efforts, and poor demand forecasting lies at the root of most planning issues. Inaccurate forecasts lead to over- or under-stocking, which in turn leads to waste, customer dissatisfaction, capacity issues, and more.

Even the best team of planners can’t adjust forecasts fast enough to keep up with the current market’s sudden — and sometimes dramatic—demand shifts.

Many businesses in the supply chain still rely on manual forecasting, which is time-consuming and prone to human error. And even the best team of planners can’t adjust forecasts fast enough to keep up with the current market’s sudden and sometimes dramatic shifts in demand. When forecasts are finally updated manually with the most current data, demand has shifted again, resulting in further inaccuracies.

This modern problem requires a modern solution — a supply chain planning solution capable of highly accurate demand forecasting. A capable platform will constantly evaluate the most recent demand data from various sources to create up-to-date forecasts. The platform will also update the forecast automatically to reflect demand changes to ensure continued accuracy in replenishment.

Strive for high-quality data

Optimized inventory planning hinges on data. And not just any data — good data, and lots of it. Demand forecasting platforms need relevant data from multiple streams to create and automatically adjust accurate forecasts, including:

- Historical reorder data.

- POS sales data.

- Internal company data, like promotions, assortment changes, and current store and DC inventory levels.

- Supplier plans, like pricing changes, product introductions and terminations, and upcoming promotions.

- External data, like weather reports or planned local events.

Many companies have all this information housed in silos across multiple departments. Businesses focused on optimizing their planning need to prioritize unifying this information within a single robust platform so the data can be used to its maximum potential.

Companies that don’t quite have a handle on their data management needn’t worry, as it’s never too late to start wrangling their valuable internal data. But these businesses would do well to seek solutions providers who can provide expert guidance during system implementation to ensure the best results.

Enhance internal and external communications

Inventory planners need to maintain the flow of information just as much as the flow of inventory to achieve success. The more visibility a business has into the entire supply chain, the better they can anticipate changes, pivot, and profit.

First, a business needs to break down communication silos between its departments. Open lines of communication between planners, category managers, marketing, and sales departments minimize the risk of business strategies and decisions negatively impacting the inventory flow. Planners need information on assortment decisions and upcoming promotional plans to forecast consumer demand accurately. Inversely, sales and marketing departments can use forecasting and replenishment data to inform future assortment and promotional plans.

The more visibility a business has into the entire supply chain, the better they can anticipate changes, pivot, and profit.

Second, retailers and wholesalers must concentrate on improving collaboration with their suppliers to gain a better insight into conditions affecting supply. This is essential for gaining promotional, product, and pricing information, as well as insight into material shortages and other potential hiccups that could impact delivery. Visibility into supply-side complications grants retailers and wholesalers longer lead times to find alternative suppliers or alter their promotional and product plans to match market realities more effectively.

Bolster capacity utilization

Planners must track thousands of units through this pipeline while simultaneously placing new orders for more products, complicating efforts to manage capacity constraints. Planning platforms can streamline ordering to allow retailers to use their DCs to their fullest potential — like housing slower-moving shelf-stable items to make space in storerooms for quick-to-spoil fresh items.

These platforms can also coordinate orders to optimize loads and improve transport fleet efficiency. Sometimes, an order doesn’t fill up a truck to capacity, effectively causing businesses to pay to ship air. Planners can instead look to their demand forecasts and add high-priority items they would otherwise be adding to their next order to the current load to maximize the truck’s capacity.

Planners can also consolidate deliveries to individual aisles while simultaneously coordinating delivery quantities that actually fit on shelves. This ensures that the goods that arrive at the stores are as easy to shelve as possible, reducing the workload for store staff.

Key inventory planning methods

Optimal inventory planning requires a systematic approach to managing stock levels efficiently. Given the complexity of the market, wholesalers and retailers often deploy a variety of methods to better predict demand, control costs, and ensure product availability.

The more common inventory planning methods include:

ABC analysis

ABC analysis is a tool used within the broader inventory planning process to help businesses prioritize their inventory management efforts. This inventory categorization technique divides items into three categories based on their importance and value.

- Category A includes high-value items with low sales frequency

- Category B includes moderate-value items with moderate sales frequency

- Category C includes low-value items with high sales frequency.

This method helps businesses prioritize inventory management efforts using criteria such as revenue, cost, margin, stock value, delivery time, and supply/demand variation.

ABC analysis is best used in environments where different items have varying levels of importance and demand. It involves classifying inventory items into categories and applying different management strategies to each category. Businesses using ABC analysis can focus resources on managing high-value items more closely, while applying less stringent controls to lower-value items.

Batch size/economic order quantity (EOQ)

The economic order quantity (EOQ) method calculates the optimal batch size to minimize total inventory costs, including ordering and holding costs. This classic method helps businesses reduce expenses associated with inventory management and provides a systematic approach to determining the most cost-effective quantity to order each time.

Businesses often use the EOQ method in stable demand environments with consistent lead times. It typically involves ordering fixed quantities regularly, ensuring a balance between order frequency and inventory holding. Businesses can use EOQ to streamline operations and maintain adequate stock levels without overstocking.

Just-in-time (JIT)

The just-in-time (JIT) method hinges on receiving goods only when they are needed in the production process to reduce holding costs. This approach minimizes inventory levels, lowering storage costs and waste. JIT provides a systematic method for managing inventory more efficiently.

The JIT method is best used in environments with reliable suppliers and predictable production schedules. It involves closely coordinating production schedules with suppliers to ensure timely delivery of materials. Businesses using JIT can respond quickly to changes in demand while maintaining minimal inventory levels.

Optical fills/presentation stock

Optical fills (or presentation stock) ensure retail shelves appear fully stocked to attract customers. This concept involves determining the minimum quantity needed for visual appeal while managing overstock risks. It helps retailers create an inviting shopping environment without excessive inventory.

This method is best used in retail settings where product presentation impacts sales. It typically requires maintaining a specific inventory level on shelves, regardless of actual demand. Retailers use optical fills to present a well-stocked appearance, enhancing customer experience and encouraging purchases.

Order cycles and delivery schedules

Proper order cycle and delivery schedule management focuses on optimizing the timing and frequency of inventory replenishment to minimize holding costs. It aligns order schedules with demand patterns to ensure a steady supply of products. This approach helps businesses maintain consistent inventory levels while reducing excess stock.

This method is best used in environments with predictable demand and reliable supply chains. It involves setting regular intervals for ordering and receiving inventory, effectively balancing supply and demand. Optimizing order cycles helps businesses reduce storage costs and improve inventory turnover.

Safety stock

Managing safety stock involves keeping extra inventory to prevent stockouts due to demand and supply variability. Proper safety stock management balances the cost of lost sales with holding excess stock and provides a buffer against unexpected fluctuations in demand or supply delays.

Retailers often rely on safety stock in environments with high demand variability or unreliable supply chains. It requires calculating the additional quantity needed to cover potential shortages. Maintaining safety stock reduces the risk of stockouts, ensuring product availability and enhancing customer satisfaction.

Supplier agreements

Businesses must consider their supplier agreements when modeling lead times, reliability, and costs to ensure a reliable supply chain. These agreements help businesses forecast supply chain performance and plan inventory accordingly. They play a crucial role in maintaining a steady flow of goods.

Retailers who find that supplier performance significantly impacts inventory management prioritize negotiating terms and monitoring supplier reliability to minimize disruptions. Effective supplier agreements enhance inventory planning by providing consistent and predictable supply chain performance.

Advanced inventory planning methods

Broader inventory planning methods address many needs but don’t cover every scenario. Companies often require advanced methods to tackle specific business challenges and achieve their goals.

Several common examples include:

- Capacity management, which plans for capacity constraints and optimizes resource use to align storage and production capacities with inventory levels.

- Material flow smoothing, which reduces bottlenecks and balances production schedules to maintains a steady flow of materials through the supply chain.

- New product introductions, which require a method that analyzes market trends and estimates productions needs to forecast initial demand and plan inventory for new products.

- Product ramp-downs and clearances for products nearing the end of their lifecycle, which necessitate a method that implements clearance sales and adjusts reorder points to avoid obsolescence and excess stock.

- Promotions management, which forecasts demand spikes and plans for additional stock to ensure proper inventory levels ahead of promotional activities.

- Seasonal management, which analyzes historical sales data and adjusts inventory based on seasonal demand fluctuations.

- Shortage management, which identifies potential inventory shortages and implements measures like expedited shipping, alternative sourcing, and safety stock adjustments to mitigate their impact.

Businesses often need to blend various methods to balance inventory needs with market and cost realities. Managing various planning models and strategies requires a robust inventory planning solution like RELEX, which can address these multi-faceted needs without introducing further complexity to the process.

5 steps to building a better inventory plan

Improvements to inventory planning processes so greatly impact revenue that returns on initial investments often pay off within a year. But for retailers and wholesalers fighting supply chain fires day in and day out, it’s not often the financial expense that discourages whole-scale changes to their system; it’s the mental expense.

A measured, intentional approach to optimizing inventory planning takes much of the sting off the work behind making systemic changes. Companies can save themselves the trouble by reading through these five steps before tackling planning challenges head-on:

1. Determine issues with current inventory planning processes

Take stock of what’s working and not in your current planning process so you know what changes to address. Ask yourself the following critical questions:

- Have you adequately trained your team? Even in the modern age of automation, planners play a starring role in keeping the ship steady. Additionally, someone’s going to need to take charge of the implementation of the new changes and the responsibility of achieving set goals. Ensure that the planning team is experienced, adaptable, and well-versed in new systems and tools as they’re introduced.

- Where are there communication gaps? Look internally and at trading partners to identify opportunities for improving communication and data flow.

- Do you have the right tools? Evaluate the existing inventory planning tool stack and identify places where performance should improve. Pay special attention to challenges in forecasting accuracy, automated replenishment, and supply chain collaboration capabilities your company can’t yet overcome.

2. Align inventory planning targets to long-term business strategies

Efficient, accurate inventory planning can have long-term results beyond profitability. Take care to consider the broader goals of your organization and identify how planning can contribute to achieving these objectives. Consider the following aspects:

- Market expansion plans. If your company plans to enter new markets or expand its product range, inventory planning should be adjusted to accommodate these changes. This might involve diversifying suppliers, adjusting stock levels, or reevaluating logistics strategies.

- Sustainability goals. Many companies are now prioritizing sustainability. Inventory planning should support this by optimizing order quantities to reduce waste, considering eco-friendly packaging and transportation methods, and choosing suppliers who adhere to sustainable practices.

- Technological advancements. Stay on top of the latest AI, machine learning, and data analytics trends, and consider how these can be integrated into your fulfillment strategies to improve efficiency and accuracy.

- Customer experience focus. Strengthen planning processes to enhance customer satisfaction. This could mean ensuring product availability, reducing delivery times, or adjusting the range of offered products.

3. Set goals

Companies can’t evaluate the success of their endeavors if they never set up hard goals. Identify which metrics will serve as key performance indicators (KPIs) before making process changes and establish a baseline measurement for these metrics to test against in the future. Depending on needs, some essential KPIs to keep track of may include:

- Percentage of stockouts

- Spoilage levels

- Days of inventory on hand

- Number of touches

Don’t forget to set recurring dates to evaluate progress, keeping in mind that minor tweaks may need to be made to keep efforts on track. These check-ins will grant planning teams opportunities to identify potential hiccups, unforeseen challenges, or even new optimization opportunities as they work toward their ultimate goals.

4. Evaluate vendors

Businesses won’t lack options when it comes to inventory planning software. The market is chockfull of robust solutions, many with adequate features and functionality.

But before comparing bells and whistles exclusively, research the vendors themselves. The vendor you choose will serve as a vital partner in achieving your planning goals, so this selection is essential to long-term success. Seek out companies with extensive experience in your sector, especially those with a quantifiable record of successful implementations. If possible, identify whether these companies align with your organization’s goals in terms of sustainability and scalability.

There are a few simple ways to determine the ideal vendor for your company’s needs, including:

- Word of mouth. Leverage existing relationships with your trading partners to get a firsthand account of their experience with specific vendors.

- Software review websites. The internet is full of free and helpful feedback from actual customers and research companies like Forrester.

- Case studies. Jump to a potential partner’s website to read success stories paralleling your organization’s goals.

- Schedule a chat. Most companies are more than willing to discuss their business and show you the ins and outs of their software.

5. Invest in better inventory planning software

The modern supply chain is too complex not to have a capable planning platform at your disposal. Planning platforms ensure that all relevant information is included in the forecasts, which no manual method could achieve. They also automate mundane, time-consuming tasks and handle complex, multi-factor optimizations. This frees planners to focus on value-adding jobs — like managing exceptions and making decisions requiring a distinctly human touch.

Software features are important to consider in the decision-making process, but so are the history and reputation of the company behind those features.

Given how integral planning software is to the overall success of inventory planning, it pays to take time and research the various platforms — and the companies that build and manage them. Software features are important to consider in the decision-making process, but so are the history and reputation of the company behind these features. Retailers and wholesalers would do well to choose a company with a track record of successful implementations and customer satisfaction, as they’ll be partners in the long term.

5 essential inventory planning software features

There’s no “one-size-fits-all solution” to planning issues, as every wholesaler and retailer has unique pain points. That said, there are several must-have inventory planning software features and capabilities that are critical to any optimization strategy, including:

1. AI-optimized goods flow

Leveling the flow of inbound and outbound goods can take pressure off a company’s often limited workforce. A capable inventory planning platform uses AI to optimize goods flow, reducing the risk of capacity bottlenecks and ensuring reliable throughput. AI-driven inventory management systems can analyze historical and real-time data intelligently to predict and prevent potential disruptions. This allows for better capacity utilization and consistently high product availability across all channels.

2. Automated, machine-learning-powered demand forecasting

It’s the 2020s, and a company’s demand forecasting needs to be highly accurate if they hope to thrive. A company’s planning platform should generate forecasts based on current data and adjust them as new and relevant information becomes available. This enables businesses to stay ahead of demand fluctuations and avoid stockouts or spoilage.

Top-tier planning platforms leverage the power of AI to optimize processes. Platforms with machine learning capabilities analyze and respond to changes at a speed and precision far exceeding human abilities. The software “learns” from events, allowing planners to concentrate on enhancing efficiency in other areas.

3. Customizable configuration

Many businesses think that no “out-of-the-box” solution could address their needs. They opt instead to develop a platform internally despite the difficulty and costs associated with building, using, and maintaining an in-house tool.

To a degree, these companies are right. No retailer or wholesaler needs the same thing from their planning solution, and it’s unlikely any default configuration of even truly excellent platforms can address unique issues as-is. That’s why it’s essential for companies to choose a planning platform built with custom configuration in mind — and to work with a software partner dedicated to engineering a solution tailor-fit to their approach.

A planning platform must stay aligned with changes in strategy and the business environment. It should enable growth and adaptability when needed, not block it. A “configure – don’t code” approach empowers the user organization to innovate and test out new concepts independently rather than deferring to programmers or external consultants.

4. Digital supply chain twin

It’s called “inventory planning,” but many businesses are stuck reacting to supply complications like material shortages or supplier product terminations. Proactive planning requires visibility into the entire supply chain — so planning software should feature a digital supply chain twin.

A digital supply chain twin, often called a digital twin model, virtually simulates the supply chain. It’s constantly updated with recent data to ensure the simulation is current and accurate. This model allows businesses to project how their strategic decisions will impact the flow of goods and information within the supply chain, resulting in smarter, more strategically sound decision-making.

5. Predictive inventory

Modern inventory planning requires more than just tracking what’s on the shelves. It should predict and correct inventory inaccuracies before they impact sales. A capable planning platform should leverage AI and machine learning to establish a more precise view of actual inventory levels, automatically detecting anomalies and correcting balance errors that could lead to costly stockouts or overstock situations.

The best platforms use probabilistic modeling to identify potential inventory discrepancies and generate prioritized recommendations for inventory checks. This predictive approach means businesses can move beyond traditional cycle counting to a more targeted, efficient inventory management process that focuses resources where they’re needed most. When combined with automated balance corrections, these capabilities can reduce inventory errors while simultaneously improving product availability and reducing spoilage.

Real-world inventory planning examples

It’s easy to get excited about sweeping changes to ingrained inventory planning processes when the idea is just that — an idea. And it can be easy for decision-makers to convince themselves to stick with a broken product when faced with the uncertainty associated with adopting a new one.

Fret no more and check out these three stories of planning optimization gone right, brought to you with help from the folks at RELEX Solutions:

Baby Bunting

Baby Bunting, Australia’s largest nursery retailer, faced inventory planning challenges due to its promotion-driven business and lack of a centralized supply chain planning platform. Stores managed their orders through time-consuming manual processes, leading to their over-ordering regular stock items and stockouts during promotions or seasonal spikes. Baby Bunting needed a centralized planning solution to improve inventory allocation, drive supply chain improvements, and support rapid growth.

Baby Bunting partnered with RELEX and achieved stunning improvements in their demand forecasting, replenishment, allocation, and promotion forecasting. The AI-enabled system eliminated manual ordering, increased availability by 7% up to 94%, and reduced inventory value by 8% in like-for-like stores. Automated, demand-based ordering improved inventory accuracy across all channels, including seasonal and promotional items. The centralized planning solution also provided visibility into store needs, enabling suppliers to prepare accurately for orders in advance.

Cora France

Leading French hypermarket group Cora France used outdated internal solutions that lacked the flexibility and scalability needed for inventory planning. Their warehouses manually handled supplier orders, and store replenishment required improvement due to complex promotional processes and variable sales on certain products. Cora knew they needed to optimize demand forecasting and automatic replenishment across their 61 stores and 12 distribution centers, and their search for an answer brought them to RELEX.

Cora achieved significant improvements in several vital areas using the RELEX platform. The company experienced a 2.0% increase in in-store availability, a 5% reduction in in-store inventory, and a 1.5% increase in distribution center availability. Cora and RELEX teams collaborated closely to ensure the rapid deployment of the new solution, managing to complete implementation within two months for warehouses and four months for stores. This partnership has provided Cora with better visibility into their supply chain and inventory, enabling continuous improvement and integration of the entire value chain with their suppliers.

Nomeco

Danish pharmaceutical wholesaler and supplier Nomeco experienced inventory planning and management issues with their outdated legacy replenishment and ERP systems. As the vendor-managed inventory (VMI) services provider for around 350 pharmacies, their complex supply chain required a modern solution to automate and streamline processes between distribution centers and pharmacies.

After partnering with RELEX, Nomeco significantly reduced manual processes, improved customer service, and increased efficiency. The company experienced reduced inventory levels while maintaining or increasing availability, even with higher sales volumes. The platform’s advanced assortment logic enabled Nomeco to quickly identify and order pharmaceutical substitutions in case of vendor stockouts. This led to an increased market share of serviced pharmacies and overall growth.

Take inventory planning optimization to the next level with AI-powered software

Inventory planning only becomes more complex as businesses scale. There are more products to order, more shelves to stock, and more places for things to go awry.

That’s why it pays to use a planning platform that has you covered. RELEX is the go-to solution for retailers and wholesalers across the globe looking to increase both stock availability and inventory turnover. We think the supply chain can be simpler and more sustainable— and we’ve built a planning platform to prove it.

Inventory planning FAQ

What is inventory planning?

Inventory planning is the process of determining the optimal type, quantity, and delivery time of products. A streamlined inventory planning process reduces the risk of costly over- and under-stocking to ensure a positive customer experience and the efficient use of a business’s storage space, transportation fleet, and labor force.

What are the chief challenges of inventory planning?

It isn’t easy to achieve success in inventory planning due to several factors, including:

- Supply and demand volatility. Material shortages and supply chain snags negatively impact a company’s ability to receive inventory on time. Meanwhile, consumer demand can shift daily, resulting in costly stockouts or excess inventory levels.

- Poor capacity utilization. Holding too much stock on hand results in costly carrying fees, waste for quick-to-expire products, and even lost sales when slower-moving items occupy space faster-selling products could hold.

- Store floor inefficiencies. Inefficient ordering results in deliveries and replenishment during peak hours, pulling store workers away from valuable work with customers.

What are the four steps to creating a new inventory planning process?

Every retailer and wholesaler experiences unique inventory planning pain points requiring unique solutions. That said, there are four steps every business can take before making substantial changes to their process:

- Identify issues with your current inventory planning process

- Set goals and determine KPIs

- Invest in better inventory planning software