It’s time to rethink availability vs. waste in your grocery supply chain

Feb 20, 2019 • 4 min

Recent research by McKinsey supports what many of us have long suspected: shoppers use the quality of a few key items to rate a supermarket’s fresh produce department, and this assessment has knock-on effects that impact sales both in fresh and other departments.

Having surveyed some 23,000 people, McKinsey found that quality outranks any other reason shoppers recommend one chain’s fresh produce over another, ahead of price and promotions.

What’s more, the research suggests that a focus on quality can increase the fresh produce department’s sales by as much as 10% a year.

Taste, texture and juiciness — the factors by which shoppers judge their fruits and vegetables — are not purely a supply chain issue; procurement has its part to play too. Still, ensuring that fresh produce is displayed in peak condition is certainly the job of the supply chain team. The good news is that when you tackle spoilage, you tackle freshness; when you tackle freshness, you tackle spoilage. They are two facets of the same problem.

To address the challenge, McKinsey urges retailers to rethink their fresh food management. Although many assume that a focus on quality leads to a higher level of waste, McKinsey has found no such trade-off because quality and waste problems often share the same root cause. In our experience at RELEX, the solution almost always begins with addressing demand forecasts for fresh food produce.

So how to do that?

Balancing Waste and Lost Sales

For fresh products, it is essential to get the demand forecasts right. Specifically, grocers must get them right on the day-level to capture demand variation throughout the week; for example, sales for a product may be high on a Saturday, but much lower on a Monday. In some cases, it may even be necessary to forecast within-day demand to support multiple replenishments per day.

However, to balance the risk for waste against the risk for stock-outs, safety stocks must also adjust in step with the expected sales volumes and forecast errors for different weekdays. After all, safety stock levels that guarantee availability on Saturday also guarantee waste on Monday, if not adjusted.

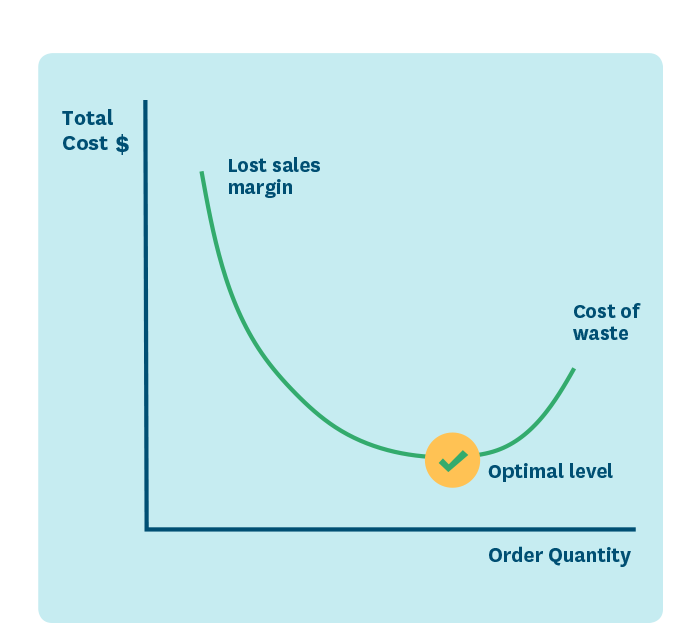

Good retail planning systems perform this kind of dynamic safety stock optimization automatically. In fact, they take it even further by also optimizing each order based on cost-benefit calculations that balance the risk of waste against the risk of out-of-stocks. The best machine learning algorithms can find that sweet spot where both the cost of waste and lost profits stemming from out-of-stocks are minimized (see Figure 1).

Figure 1: Best-in-class retail planning systems optimize each order based on cost-benefit calculations that balance the risk of waste against the risk of out-of-stocks.

Tangible Results

Improving availability and reducing waste at the same time is not only possible but should be the target for all food retailers. German grocery retailer Bünting, for example, has cut spoilage by more than 23% while pushing their availability to over 98%.

Even better, the investment in improved forecasting and replenishment has generated a range of additional benefits. By managing both fresh and ambient product replenishment in the same system and optimizing delivery schedules, Bünting has been able to cut fleet costs by 27%, sharply reducing CO2 emissions. The more level goods flows have enabled the company to organize staff time more efficiently, ultimately driving savings of almost €1M p.a.

Britain’s leading regional supermarket Booths also decreased its overall spoilage by around 10% while simultaneously increasing shelf availability. It’s easy to agree with Booths’ former IT and eCommerce Director Andrew Rafferty, who implemented the new forecasting and replenishment system, when he said “Improving availability and cutting spoilage doesn’t have to be an either/or. We managed to cut spoilage with no adverse impact on availability at all.”

Getting it Right

It’s important to remember that automation should not mean creating a black box. Rather, it should mean lightening the load on planners so they can focus on areas where their expertise really makes a difference — most notably, exception management.

A good retail planning system allows you to interrogate it. If there’s a problem, say the spike in spoilage that some grocers experience on a particular day of the week, you should be able to locate the root cause, such as systematically lumpy demand.

Other issues worth being aware of include over-large batch sizes and space-driven spoilage, where too large an area has been allocated to a fresh item and minimum display requirements lead to stock exceeding demand.

For an in-depth look at how to zero in on cutting spoilage while increasing freshness, with all the benefits that brings for customer satisfaction and your bottom line, check out the RELEX guide to Best Practices in Managing Grocery Retail Supply Chains.