4 strategies for managing fresh fruits and vegetables in grocery retail

Aug 16, 2024 • 7 min

Grocery retail isn’t for the faint of heart. From high levels of competition to razor-thin margins, grocers face challenges that rarely have simple solutions. Among these, ultra-fresh products like fruits and vegetables pose some of the greatest difficulties. They’re unlike any other category in food retail, but they also comprise one of the largest revenue streams and opportunity centers.

Let’s look at four common challenges in fruit and vegetable management — and strategies for turning those obstacles into opportunities.

Challenge 1: Inventory shrink

Because fruits and vegetables are sometimes sold by weight rather than unit, grocers must account for inventory shrink. If you order three cases of crackers, you can rest assured that volume won’t change over time. Three cases of avocados, though, will lose weight and value as they approach spoilage, and carrots lose value when shoppers tear off leafy greens they don’t want to pay for. You can’t re-sell those carrot tops alone, after all.

Most grocers lack the inventory data necessary to measure, track, and counter inventory shrink.

Solution: AI-based predictive inventory and accurate spoilage estimation

If inventory data is missing, grocery retailers can build a picture of inventory from transactions. It’s also possible to identify discrepancies and predict inventory drift, maximizing accuracy and calculating on-hand inventory, which is critical for strategic ordering.

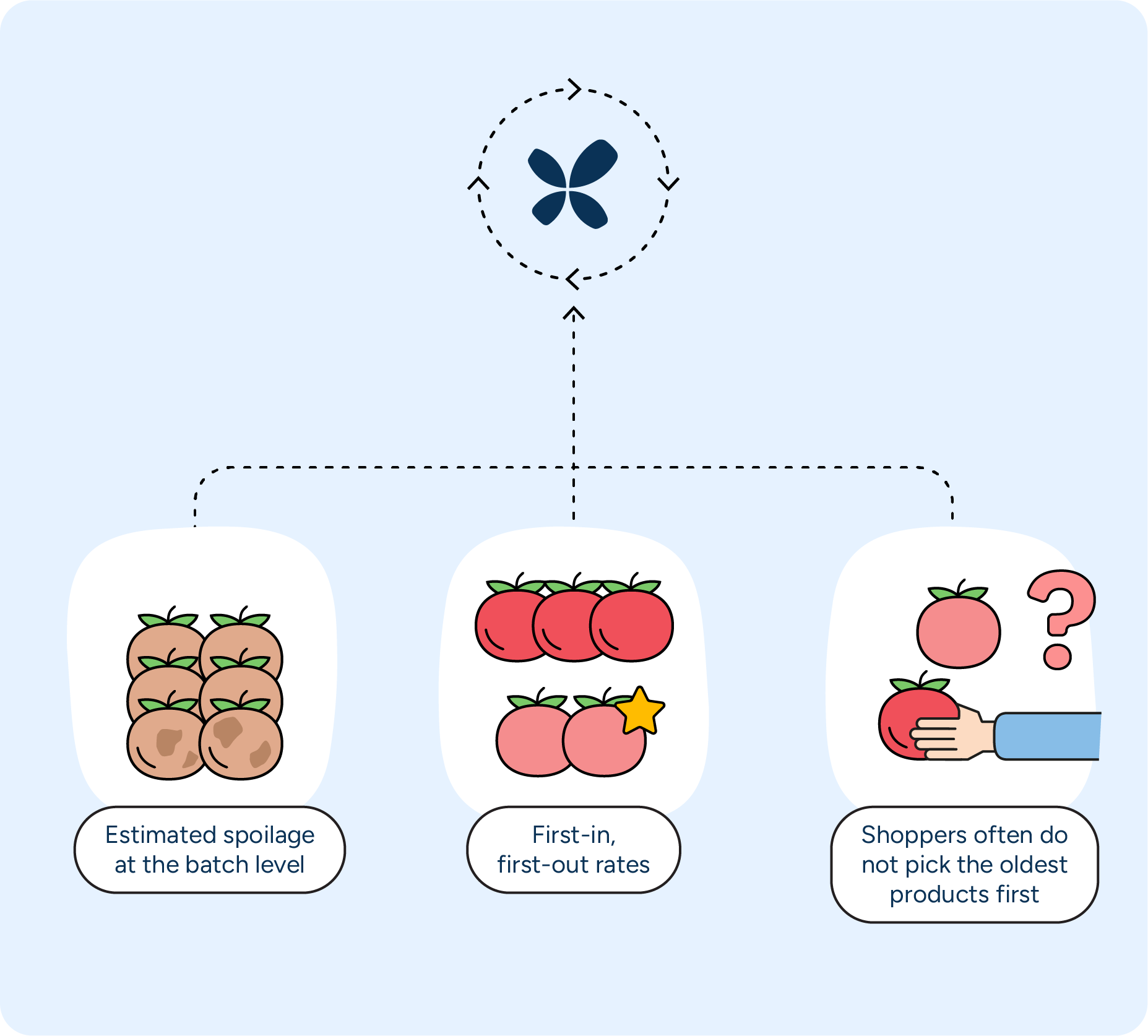

When it comes to spoilage, grocers must account for shrinkage in their inventory projections to maintain service levels. A planning solution that integrates shrink data into balance projections will better position planners to place orders that improve availability. For instance, purpose-built machine-learning algorithms can estimate spoilage at the batch level and determine how much should be ordered in the coming days. The batch balance logic also considers FIFO rates and accounts for the fact that shoppers often do not pick the oldest products first.

Challenge 2: Extreme variability and complex spoilage timelines

Short assortment periods further complicate fresh produce planning. Harvest unpredictability means planners often work with just a one-week horizon for fruits and vegetables. You may expect the orange season to begin in late October when planning six months in advance, but plans go out the window if it starts in November — and the same applies to the season’s end.

Then consider that orange shipments come from multiple vendors from multiple countries providing multiple variants of oranges. Each shipment can fluctuate wildly in amount, size, quality, and price depending on what these vendors can supply — and that’s just for one fruit out of all the fruits and vegetables you stock. A time-series forecasting model is quite effective for more predictable products, but even the most accurate historical data is useless in the face of extreme variability.

Varying expirations and delivery cycles make it difficult to manage demand that varies from day to day and season to season. Planners face the challenge of finding a cost-optimized approach to reduce grocery store food waste and protect margins while meeting availability and freshness expectations.

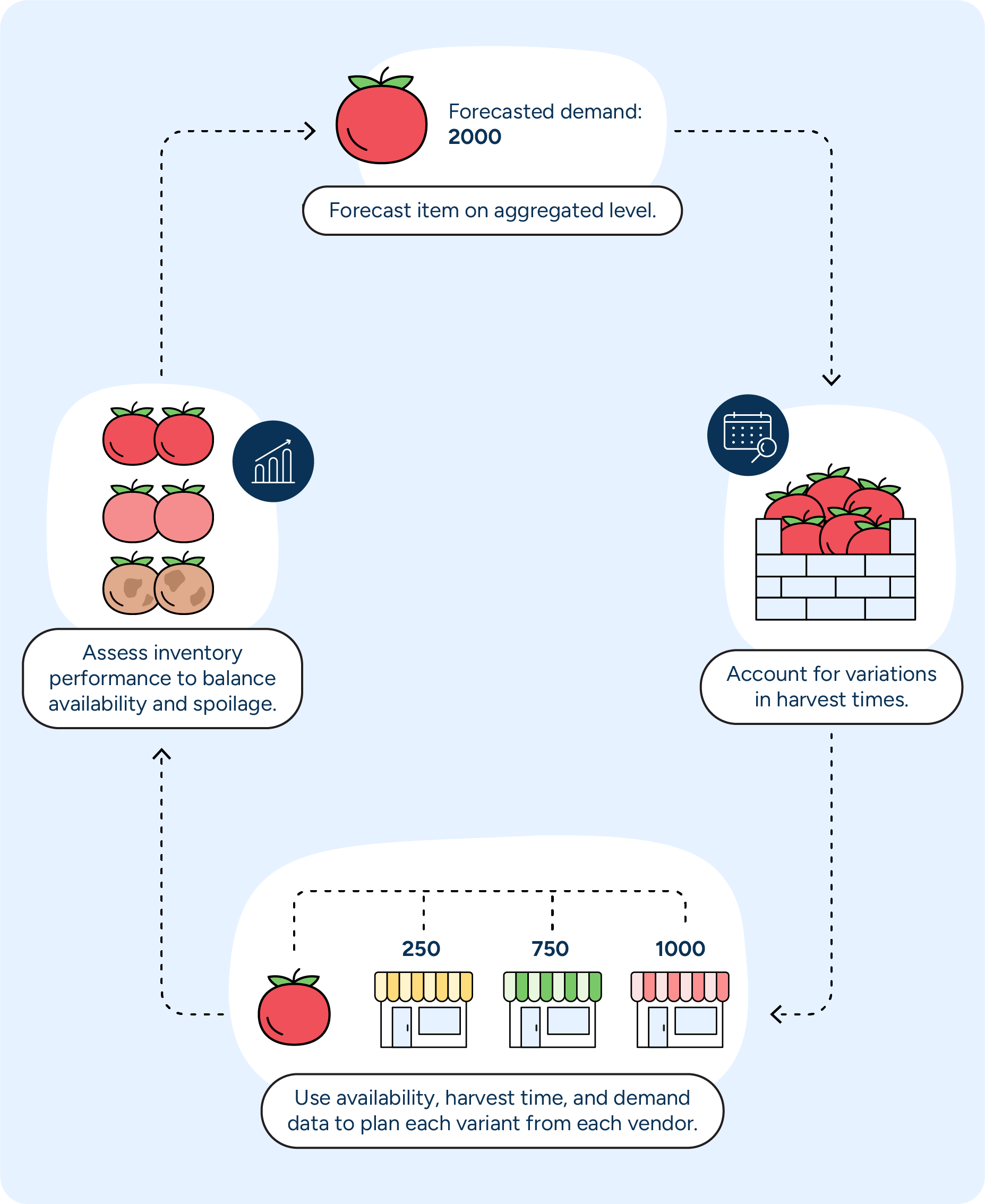

Solution: Accurate ML-based forecasting and adaptive safety stocks for ordering fresh produce

Grocers can use machine learning algorithms to ensure the most accurate, up-to-date forecasts and replenishment possible. Machine learning can, for example, adjust lifecycle demand patterns to match changing harvest patterns or use localized weather data to connect the dots between warm weather and increased demand for fresh fruits and salads.

The more flexible the planning system, the more quickly planners can adjust to the most recent information available within a short assortment period. A forecasting solution should, for example, let you move a forecast out by weeks if the harvest starts late. At the same time, price elasticity can model demand against sell-prices to ensure your order amounts maintain availability and prevent spoilage.

Grocers may also take advantage of adaptive safety stocks that balance availability and spoilage. These parameters identify safety stock that will minimize costs based on sales forecasts, expected waste, and expected lost sales.

Challenge 3: Complexity of product variants and substitutions

Variability also means fruits and vegetables experience significant demand shifts based on availability, quality, and the store’s needs. Low availability is incredibly damaging in fresh retail, and stores must calibrate purchasing, planogramming, replenishment, and promotions to ensure full displays.

If yellow onions run out, filling that space with red onions makes sense, even if it’s not ideal — that’s simple enough. If a store has too many red onions and not enough yellow, it could promote the red variety to force cannibalization, preventing a stock-out on the low-availability item while mitigating the risk of spoilage for the overstocked one.

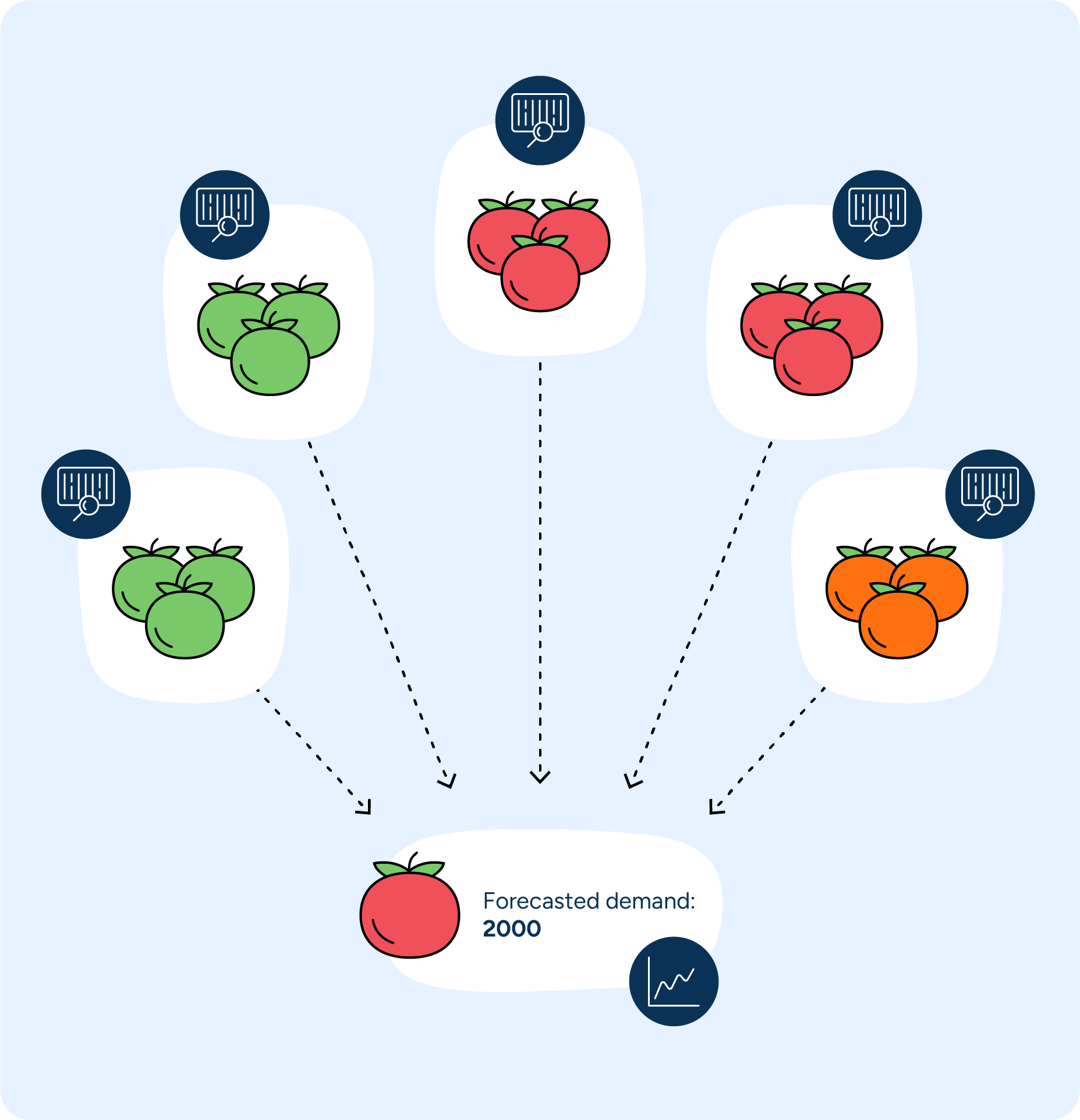

However, one of the greatest challenges — and opportunities — in fresh management might be its massive amount of master data. Few grocers stock a single variant of apple, for example. Most stock a range, such as Red Delicious, Golden Delicious, McIntosh, and Granny Smith — plus the organic variant of each. Of these eight, each item may have multiple product codes that reflect supplier, country of origin, and so on.

Solution: Granularity and aggregation for flexible control

Only a best-in-class planning system can effectively manage the volume and complexity of this master data. Suppose you have 20 product codes for apples. In that case, the right solution can aggregate those codes and forecast them on the group level rather than forcing planners to forecast each individual product code.

It will also let you filter on a more granular product-location level. This allows planners to forecast demand specifically for locally sourced apples, imported apples, organic apples, and so on.

Challenge 4: Manual ordering that requires expertise

The three previous challenges revolve around data – how to correct, process, and use it.

However, many fresh retailers don’t generate order proposals for fresh produce from a centralized planning hub. They rely on experienced store employees to place replenishment orders. Often, those employees can only rely on gut instinct and highly manual processes. They have little to no visibility into upcoming promotions and other demand drivers and little recourse to decision-making support.

This leaves a crucial question unanswered: How can retailers ensure accurate replenishment orders for each store within a decentralized planning network?

Solution: An intuitive mobile tool that streamlines store ordering

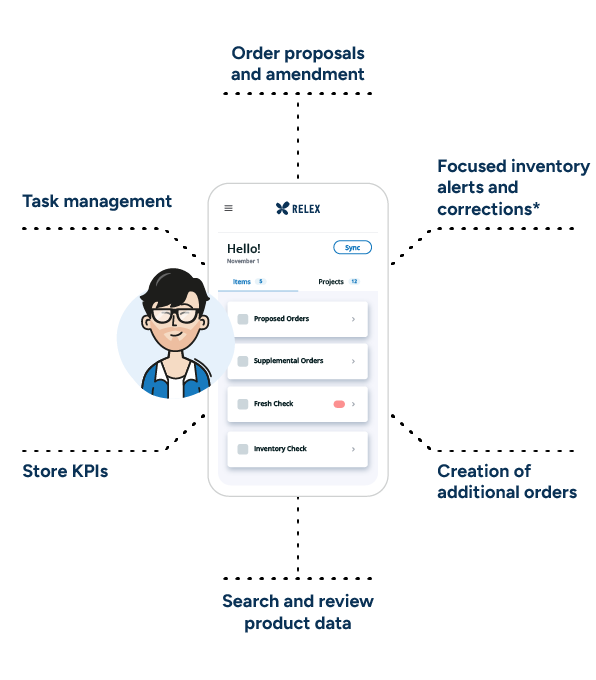

A store execution solution should complement and integrate with an AI-driven planning engine, opening up a two-way line of communication between stores and planning teams. Solutions like RELEX Mobile Pro ensure that insights from the AI engine get into the hands of store employees while also helping planners attain store-level insights for better calculations. Here are three advantages to using this kind of solution:

- The app gives store employees a clear view of on-hand inventory, order suggestions, and other recommended actions to help them prioritize tasks.

- Store employees can drill down into the data behind the recommendations and amend those suggestions based on their local expertise.

- Even less-experienced store employees can easily make optimal ordering decisions.

This symbiotic relationship between stores and the network-wide planning solution helps retailers avoid spoilage, protect margins, and provide consumers with the freshest possible items.

Transforming the value chain

The health of a fresh department is critical to profitability, but suboptimal processes cost grocers millions each year. On an even broader scale, one-third of food is wasted globally, with 17% of that waste occurring upstream in the supply chain.

Of course, no single solution can solve every problem at once, but there’s an enormous, untapped opportunity to capitalize on these challenging ultra-fresh products. To do so, grocers must systematically improve the entire value chain:

- Master your master data.

- Ensure space and replenishment plans react quickly to changes in demand.

- Improve operational efficiency in stores.

- Enable longer planning horizons despite short assortment periods.

This kind of value chain transformation calls for close cooperation between a wide range of stakeholders — from supply chain to assortment planners, from demand planners to store associates. However, those willing to redesign and unify their approach to fresh management can turn old challenges into a new competitive advantage while increasing sustainability and reducing waste throughout the supply chain.