MIT research: The effects of dynamic safety stocks on inventory and service levels

Mar 29, 2019 • 4 min

We worked alongside Dan Covert and Joaquin Ortiz on their Master Thesis “Dynamic Customer Service Levels: Evolving Safety Stock Requirements for Changing Business Needs” for the Massachusetts Institute of Technology. RELEX was used to simulate the dynamic safety stock levels suggested by their research. The following post describes how dynamically changing desired service levels during promotion or seasonal periods will ensure accurate safety stock levels and reduce manual interventions.

KEY INSIGHTS

- A firm that manages items with varying importance throughout the year can use dynamic service levels to have the right inventory at the right time.

- To build trust in an inventory policy, the insights and experience of key stakeholders should be used in developing the policy.

- When setting safety stock levels, buffering for forecast error instead of demand variability leads to better product availability.

The Right Inventory at the Right Time

“Take what we’re forecasted to sell and add 20%. Whatever you do, don’t be out of stock!”

During holidays or promotions, this method of inventory management is all too common. Companies invest years and millions of dollars optimizing inventory, but when emotions are high, these strategies fall by the wayside.

These methods are especially prevalent in food retail. Grocery stores jockey for market share by offering deep discounts through promotions. Competing chains strive to stand out during holiday periods. Running out of key items could lead to a permanent loss of customer trust. Inventory managers feel immense pressure to avoid these situations, and the pressure to order a “little extra” inventory is apparent.

Through a partnership with Retail Business Services (RBS), an Ahold-Delhaize company, our research sought to eliminate emotionally driven ordering by mathematically incorporating buyers’ intuition into inventory models.

Incorporate the Intuition

When faced with pressure to avoid out-of-stocks, we found that replenishment buyers needed to trust that their inventory policy would meet the demands of the business. Specifically, the inventory policy needed to carry the right amount of safety stock on important items. Without trust in and understanding of the system, it was easy for buyers to deviate and create manual orders. Therefore, to win their trust it was important to incorporate their intuition into designing a new inventory policy.

From our discussion with the replenishment buyers at RBS, there were several different criteria that led them to create manual orders:

- Items that were promoted or critical to a holiday received special attention. The management group at RBS created manual workarounds to ensure that distribution centers had the entire inventory they needed on these products, and then some.

- If a vendor was known to not deliver in full, buyers might increase the order size in hopes of getting what they wanted.

- For certain items such as baby formula, there were legal ramifications to being out of stock, so extra inventory for these key items was always on hand.

Traditionally, companies would set safety stock levels based on some type of ABC segmentation. This method follows the 80/20 rule, which states that 80% of sales come from 20% of the items. Items making up a majority of sales would be dubbed “the most important” and would get the highest safety stock levels. This segmentation strategy, however, ignores buyers’ intuition and their knowledge of upcoming promotional or seasonal activities, meaning that items’ safety stock levels wouldn’t be adjusted to reflect potential upcoming peaks.

Intuition Meets Application – Simulating the Effectiveness of Dynamic Safety Stock Levels

Instead of fixing safety stock levels based on ABC segmentation, we incorporated buyers’ intuition into the safety stock calculation. Taking the four key criteria (Promotion, Season, Key Item, and Vendor Dependability) that led to manual orders, we created a decision tree which segmented items into 16 different classes. Each class was given a desired cycle service level that determined the level of safety stock for each item. Throughout a year, an item could fall into any of the 16 classes depending on which of the four key criteria it met. This approach led to dynamic safety stock levels dependent on the importance of the item.

To evaluate the effectiveness of dynamic safety stock levels, we constructed two different simulations. We first used the simulation software VenSim to model the system dynamics of the MRP policy. The VenSim simulation is highly interactive and helps users build intuition around the ordering flows and the effects of safety stock levels. We ran a second set of simulations in RELEX, which RBS uses for forecasting and replenishment.

Using each software, we ran a variety of different simulations comparing the current system settings to the dynamic safety stock levels set through the decision tree. We selected a diverse set of items including both fast and slow movers, and items with frequent and infrequent promotional schedules. Our item selection criteria also included items that were frequently manually ordered or had specific seasonal importance.

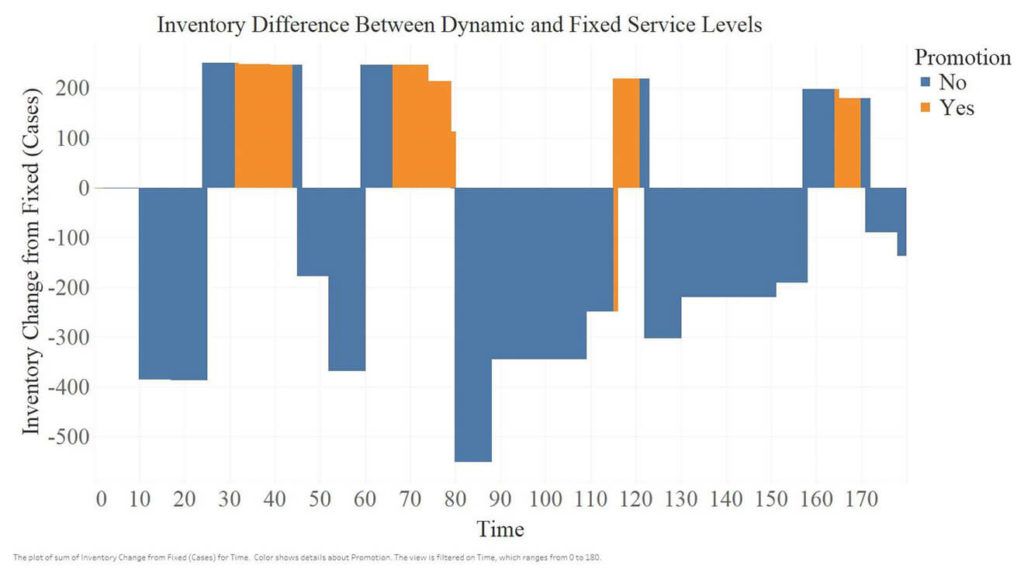

The key finding of the research is apparent from the simulation which shows that dynamic safety stock levels reduced inventory while maintaining the same or better fill rate than an ABC strategy. Figure 1 shows that inventory was dramatically reduced during non-promotional periods, but increased during promotions. Furthermore, incorporating buyers’ intuition and experience into the inventory model helped ensure trust in the system and reduce manual orders.

In the grocery business, a majority of items do not have the same importance throughout the entire year. Dynamically managing safety stock ensures that a firm carries the right inventory at the right time, without manual intervention.

Figure 1: Figure 1 Inventory differences between dynamic and fixed service levels

Read the Master Thesis “Dynamic Customer Service Levels: Evolving Safety Stock Requirements for Changing Business Needs” here.