How to manage product assortment ripple effects with planning software

Jul 10, 2024 • 10 min

Brian F. Harris developed one of the more well-known and widely used frameworks for assortment planning back in the 1980s. Even then, the category management pioneer understood the importance of the correct product assortment within a category for decisions like store space management or promotion planning.

But the world has grown both more connected and more complex since the 1980s, and retail has been no exception. Category managers are tasked with making important decisions on often vast assortments using reams of data. With the retail market more competitive than ever, retailers can’t afford to have these decisions create unforeseen, costly negative consequences elsewhere in the value chain.

Fortunately, technology has also changed a smidgen in the last 30-plus years. A digital transformation is occurring within the tried-and-true assortment planning framework of yesteryear — a sea change driven by the increased adoption of advanced tools and artificial intelligence. Retailers need these capabilities packaged within a robust planning platform like RELEX to manage the far-flung effects of product assortment decisions and optimize the entire retail value chain.

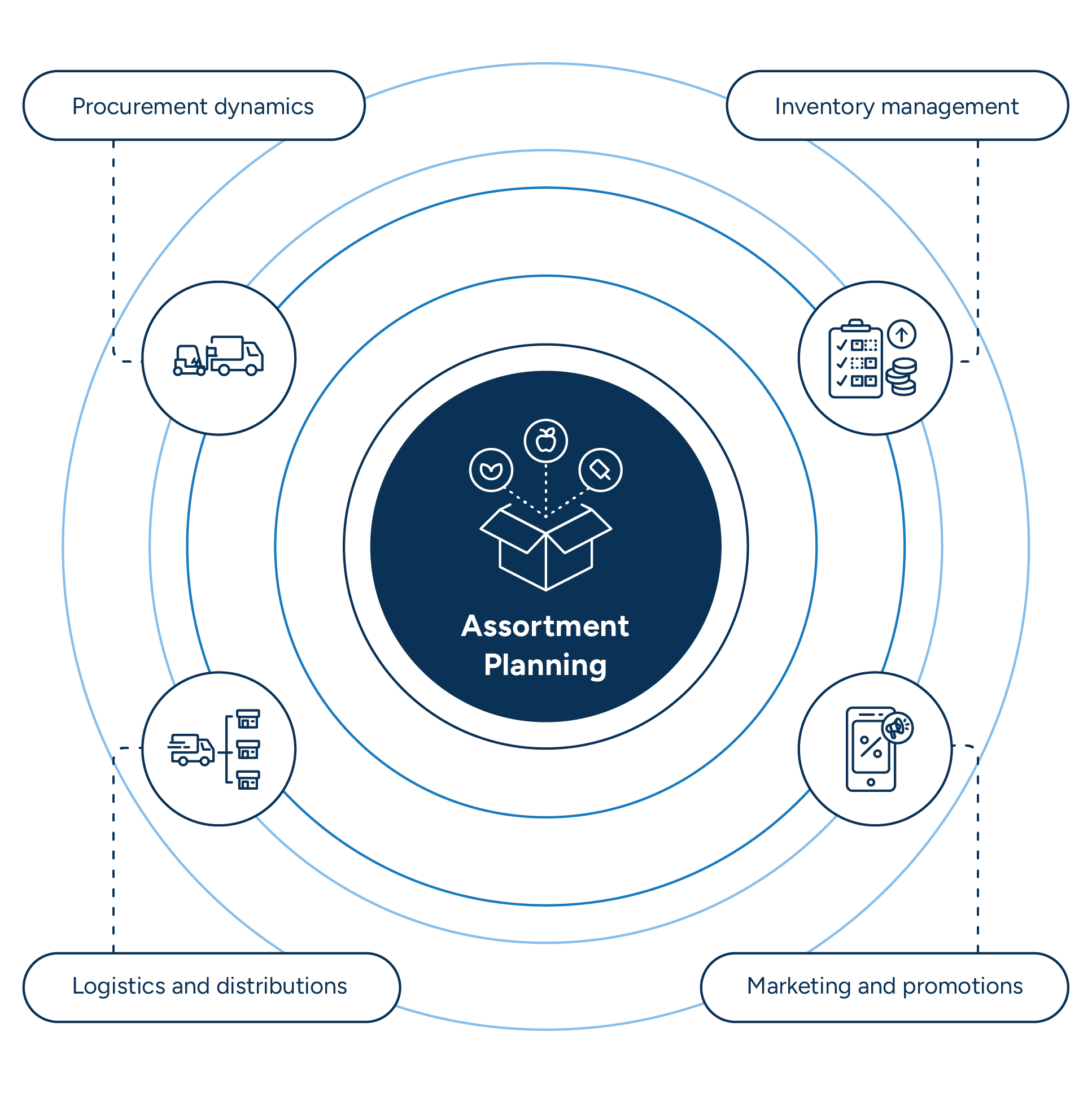

Product assortment decisions impact the broader value chain

Assortment planning is critical to retail success, impacting everything from what gets stocked on shelves to the overall shopping experience. But assortment decisions influence more than just the sales floor. They reverberate throughout the retail value chain like ripples in a pond, with decisions on product mix and placement having far-reaching effects on:

- Procurement dynamics, shaping how retailers negotiate with suppliers and manage the flow of goods, ultimately affecting product availability and cost-efficiency.

- Inventory management, affecting stock levels and the costs associated with excess inventory and stockouts.

- Logistics and distribution, influencing transportation costs, delivery times, and where stock is allocated within the network.

- Marketing and promotions, determining how products are advertised and promoted across different channels, influencing consumer perception and demand patterns.

Like pond ripples, the impact of assortment decisions magnifies as it travels throughout the retail value chain — meaning poor planning decisions and their associated costs can cascade into significant negative consequences.

For instance:

- Inadequate assortment decisions strain supplier relationships and disrupt procurement, leading to unpredictable product availability and increased costs…

- …causing inventory imbalances, with stores may face overstocks of some items and shortages of others, tying up capital and affecting sales…

- …necessitating last-minute adjustments in logistics, increasing transportation costs and complicating distribution schedules, which delays product availability to stores…

- …preventing effective promotions and reducing customer engagement, hurting sales and brand loyalty.

Fortunately, the inverse is also true. Strategic, optimized assortment planning can have positive effects throughout the broader retail value chain through improved supply chain synchronization, enhanced inventory turnover, and increased profitability.

The challenges of managing product assortment ripple effects

Strategic assortment planning is difficult to perform even when considering just the immediate macro and micro space planning implications of decisions. Determining the long-term consequences of such choices can feel outright daunting, especially considering continuous market volatility and supply chain uncertainty.

The chief challenges in making strategic assortment decisions include:

1. Managing timeframes

Product assortment planning requires selecting the right products for specific seasons or times of day while adjusting to dynamic market conditions. Grocery stores transition from featuring Halloween costumes in October to displaying holiday wares in December to stocking gardening supplies in the spring. Each decision must align with both the macro space planning of store layouts and the micro-level decisions of retail planogramming to optimize sales and customer experience.

2. Managing locations

The complexity increases as retailers aim to allocate specific goods to the right locations. Factors such as store size, region, customer behavior, and proximity to distribution centers must be considered, demanding a sophisticated process known as store clustering. Choosing a suitable model for store grouping is essential for meeting varied customer demands and shopping patterns, which vary significantly across different locations.

READ MORE: Store clustering: 5 pitfalls and how to avoid them

3. Coordinating between stores and HQ

Assortment planning also demands meticulous coordination between retail headquarters and individual store operations. This coordination is crucial for determining the appropriate product mix for each location and timing for product rollouts, ensuring that stores are commercially sustainable. Effective communication across merchandising, marketing, and supply chain teams is necessary to adapt to upcoming changes in product offerings and align the entire value chain.

4. Considering consumer cost-consciousness

Retailers also face challenges from shifting consumer purchasing power. As consumers increasingly weigh product value against price, promotional strategies become crucial in driving purchasing decisions. The economic environment, characterized by budget constraints and fluctuating market trends, requires retailers to be agile in adapting their offerings. This adaptability is vital for maintaining competitiveness in a market where consumer preferences can shift rapidly.

6 strategies for managing smarter assortments using planning technology

The factors that complicate the life of category managers would be difficult to manage manually even if they constantly remained static. Instead, they remain in constant flux, rendering conventional assortment planning methods utterly ineffective.

Optimally managing assortment — and the subsequent ripple effects — requires a robust planning solution like RELEX. These tools give category managers data-driven insights into assortment performance, enabling proactive adjustments. The technology also consolidates relevant information into a unified platform, enhancing decision-making speed and transparency across the retail value chain.

Armed with a powerful planning solution, retailers can:

1. Harness AI for efficient category management and buying

Traditional assortment planning methods are effective to a point but often lack the speed and precision needed to stay ahead of competitors. More than ever, retailers are turning to AI-powered planning solutions and their advanced algorithms and machine learning to transform their assortment management processes.

Retailers can use AI capabilities to provide real-time insights into emerging trends and consumer behavior. This capability enables category managers to quickly adapt assortments and ensure inventory aligns with shifting market demands, reducing the risk of unsold stock. An AI-powered solution’s ability to continuously analyze vast amounts of data enables it to identify patterns and shifts that might be missed by manual analysis, allowing retailers to stay ahead of trends and maintain a competitive edge.

AI also helps retailers streamline the assortment review process, automating complex analyses and providing actionable recommendations. Automation reduces the time and effort required for manual assortment evaluations, allowing category managers to focus on strategic planning. AI-driven tools analyze sales performance, customer preferences, and seasonal variations to offer precise adjustments to assortments, increasing efficiency and accuracy to better inform decisions and optimize product mixes.

Automation reduces the time and effort required for manual assortment evaluations, allowing category managers to focus on strategic planning.

AI-powered planning solutions even aid the buying process. The technology can predict future product performance based on historical data and market trends, helping buyers make informed decisions about which products to purchase and in what quantities. This enhanced demand forecasting accuracy helps retailers minimize the risks and costs associated with overstocking or stockouts.

2. Enhance cross-departmental communication

Category managers are central to operations but face challenges in ensuring efficient decisions flow to other functions, such as merchandising. Effective planning requires the most recent information, and the effective communication of assortment changes and decisions to departments like supply chain and marketing is essential to success.

Fortunately, advancements in planning technology have resulted in powerful tools that can greatly aid in streamlining communication and collaboration across functions. For instance, those implementing assortment changes on planograms can view such information as it is updated, enabling smooth execution at the customer-facing level.

Similarly, category managers can incorporate feedback from store personnel and category merchandisers into the assortment planning process to optimize assortment planning. Software like RELEX even allows proactive communication of upcoming changes and feedback collection at the SKU level to ensure alignment with real-time market demands and improve overall inventory accuracy.

3. Align product assortment and merchandising for smarter space planning

Decisions on assortment or merchandising don’t always align. Category managers determining assortments for specific store sizes sometimes discover that selected items won’t fit on shelves or leave excessive white space — a problem exacerbated by limited communication.

The right planning software can spare category managers from this dilemma, helping them anticipate these issues and establish a real-time feedback loop to address potential errors. For instance, RELEX factors space data into assortment planning and seamlessly integrates finalized assortments into space planning — complete with category manager comments!

Robust assortment planning software can help remove underperforming products from assortments while considering category breadth and depth to avoid contradictory strategies. Automating assortment removal frees up physical store space and optimizes sales distribution.

This capability supports strategic planogramming decisions and automates the planogramming process. RELEX customers who optimize planograms in combination with assortment removal suggestions can reduce the recurring shelf refill needs by 15%. Category managers who use receipt data can also identify frequently co-purchased products, further informing planogramming decisions.

RELEX customers who optimize planograms in combination with assortment removal suggestions can reduce the recurring shelf refill needs by 15%.

Combining product assortment and space planning within the same platform helps automate much of the category review process. This automation allows new assortment changes to flow into space planning tools to automatically generate optimized planograms across multiple locations, using human validation to ensure accuracy.

4. Support strategic pricing and promotion planning

Promotions and pricing strategies are closely linked with assortment planning, meaning category managers and key stakeholders often collaborate closely to implement them effectively. Pricing is especially critical for informed category decision-making, necessitating readily available information.

The right solution can significantly influence upfront marketing campaign planning. Clear plans regarding product placement across assortments and stores help teams strategically prepare marketing initiatives in advance, ensuring smooth operations and resonant promotions throughout the year. Comprehensive assortment planning software like RELEX also ensures regional product mixes align with customer needs, enabling tailored marketing campaigns.

Accurate assortment plans also provide insight into retailers’ marketing strategies for upcoming seasons, informing their approach to product bundling. They also help companies plan which items fit specific campaigns during certain time periods, which allows them to make educated purchase decisions to buy batches of these campaign items in the right quantity.

This optimized campaign planning process can decrease marketing spend and save it for more effective use. More intentional, effective spending can increase sales — a particularly attractive benefit during economic downturns when consumers are especially cost-conscious.

READ MORE: Unified pricing and promotion planning: The key to pricing precision and powerful promotions

5. Encourage stronger, simpler supplier collaboration

Depending on the retailer’s approach to supplier collaboration, a product assortment solution serves two primary purposes: increasing negotiation power and fostering enhanced collaboration and transparency.

A planning solution helps retailers strengthen their negotiation power in supplier relationships. Optimizing assortment helps retailers identify essential and underperforming items in their categories, enabling them to make informed decisions about their inventory and focus on high-demand and high-margin products. Retailers can also use the software to better understand buying patterns and demand, allowing them to plan their purchasing volumes more effectively.

With a clear understanding of their optimal assortment and precise demand forecasts, retailers can approach suppliers with concrete data to support their negotiation arguments. They can demonstrate their commitment to specific products and volumes, potentially leading to more favorable commercial terms like better pricing, extended payment terms, or exclusive deals.

Additionally, tracking and analyzing sales performance data helps retailers identify trends and shifts in consumer preferences. This knowledge empowers them to negotiate for products that align with emerging trends, further strengthening their bargaining position with suppliers.

Effective planning solutions must provide the mutual sharing of information to foster trust and certainty between retailers and their suppliers.

That said, truly effective collaboration is built on trust. Effective planning solutions must provide the mutual sharing of information to foster trust and certainty between retailers and their suppliers. RELEX allows retailers to view real-time assortment data and accurate demand forecasts, helping both parties effectively identify and address inefficiencies in category or brand strategies. This openness also helps to optimize manufacturing processes and reduce costs through minimized inventory and waste reduction.

READ MORE: How to achieve effective supply chain collaboration

6. Optimize supply chain management

Integrating supply chain data into assortment planning helps avoid unprofitable purchasing decisions. Category managers and buyers drive assortment planning decisions, and their selections dictate the range of products retailers offer. These choices significantly impact supply chain requirements, making it essential for category managers and supply chain teams to ensure efficient material and product flows through effective collaboration.

But the assortment planning process often omits critical supply chain data like costs and efficiency metrics despite their crucial relationship to SKU true profitability. Assortment planning supported by supply chain data helps identify underperforming products, facilitating their removal to reduce inventory levels and increase turnover speed. SKU optimization enables more efficient use of warehouse space, decreasing the levels of low-turnover items to reduce warehouse costs.

Retailers can also use assortment insights to group items commonly sold together, streamlining operations in distribution centers and e-commerce fulfillment locations. This practice also enhances the picking process and overall warehousing operational efficiency.

Assortment planning tools also provide valuable data on product performance and market trends. The resulting improvement in demand forecasting accuracy enables more effective inventory management and production scheduling, enhancing supply chain efficiency and cost savings.

Complex product assortments require unified planning solutions

Effective assortment planning is crucial, but the ripple effect in retail works both ways. Decisions and events elsewhere in the value chain can significantly impact assortment decisions for better or worse. True mastery in category management demands a unified approach integrating various retail and supply chain planning facets. This ensures that product assortment strategies are proactive and responsive, dynamically adjusting to changes across the value chain.

RELEX Solutions embodies this holistic approach with its advanced planning platform, uniting robust capabilities in assortment planning, supply chain management, and predictive analytics. The RELEX platform enhances functionality through a unified system architecture, ensuring real-time visibility and coordination across departments. This integration amplifies operational efficiency and strategic agility, allowing every value chain segment to inform and reinforce the others.

With a retail value chain this interconnected, retailers can’t afford to be disconnected. Prepare for future assortment planning success with RELEX.