When good retailers have to deal with bad inventory data

Picture a busy Saturday morning at your local grocery store. The inventory system shows 50 units of a popular item in stock, but store associates find empty shelves and nothing in the stockroom. This “phantom inventory” scenario isn’t isolated – it plays out thousands of times daily across retail operations worldwide. In fact, up to 60% of inventory records can be incorrect, and the impacts span far beyond the store itself.

Bad inventory data creates an end-to-end cascade of problems: demand becomes skewed, replenishment misses its mark, and store associates are put under unnecessary strain to store and manage too many or too few items. The stakes are even higher for grocery retailers, in particular. Perishable items like fresh produce, dairy, and meat are especially sensitive to mismanagement, and the costs of spoilage or lost sales due to stockouts can add up quickly.

Phantom inventory and its role in perpetuating inaccurate inventory decisions

Phantom inventory occurs when an inventory system shows products as available in stores when they are not. The impacts of phantom inventory extend beyond on-shelf availability and customer experience, causing significant disruptions throughout the replenishment process.

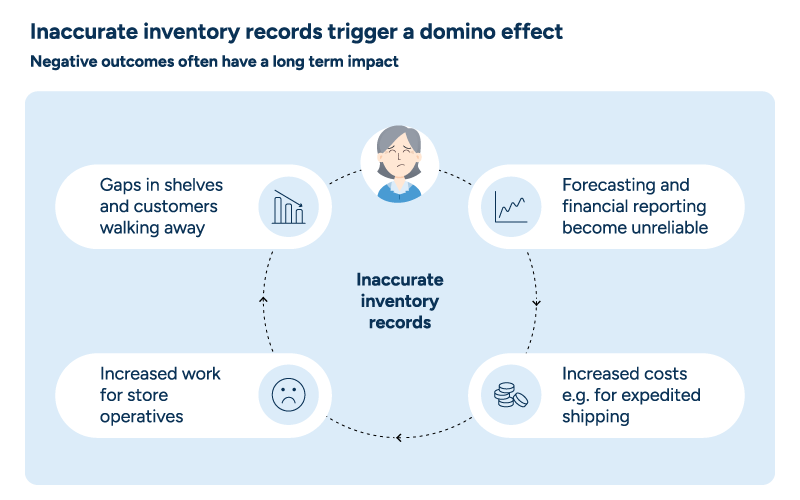

Think of phantom inventory as a game of dominoes. First, goods are received but might not be scanned correctly, creating issues around how much of an item you have on hand and how much is on shelves. When to replenish becomes a painful, expanding cycle of inaccuracies that increase the risk of stores ordering products either too soon or too late. Too soon, and some items’ storage capacity and spoilage windows suddenly become strained. Too late, and on-shelf availability is compromised, creating lost sales and frustrated customers.

While inaccuracies can be caused by issues like theft, customers moving items around, or associates not recording wasted products, the effect is the same. Inaccurate records create a ripple effect on forecasting, resulting in sales and inventory misalignment. Expedited orders to fix the gap incur extra procurement and shipping costs. In turn, these impromptu orders impact an increasingly stressed labor force, who are also dealing with an increasingly frustrated customer base.

This issue is especially common in fresh grocery, where items are loose, unpackaged, or moved frequently by customers. For instance, customers swapping produce bags or relocating produce to different areas can easily contribute to phantom inventory, and infrequent inventory audits often delay exposure to these issues.

To reverse the domino effect, retailers need an AI-powered solution where machine learning anticipates inventory drift and immediately flags inaccuracies. The impacts of any lingering inaccuracies and phantom figures can then be calculated in near real-time to present the most effective corrective actions.

Reversing the domino effect of phantom inventory

Our approach to smart inventory management targets reducing the effects of phantom inventory and turning inventory management into an optimized function. When it comes to continuous improvement of inventory management, grocery retailers have three primary goals:

- Reduce waste: When it comes to reducing waste, retailers know that countless dollars can be saved if they can optimize replenishment levels. No more wasted orders for goods that have to be discounted to sell them or, worse, spoil outright and have to be thrown away.

- Optimize labor: Labor costs are sometimes under-discussed from an optimization perspective. However, when it comes to inventory management, warehouse and store workers are often the ones who would benefit the most from smarter day-to-day inventory management.

- Boost sales: The ultimate goal of any retailer is to boost sales and their competitive advantage. Overcoming inventory issues to ensure a continuous supply of what’s needed at the right time and place helps ensure customer satisfaction and loyalty.

While addressing these concerns individually is important, the path to greatest success lies in approaching them holistically through a platform that simultaneously realizes benefits to all three. RELEX has been developing and using AI since our inception, and we invest almost 30% of our revenue back into R&D. We’ve built a comprehensive AI solution tuned to the needs of the grocery industry that forms the foundation for smarter inventory management.

On-demand webinar: The disappearing act:

Retail’s guide to conquering phantom inventory with AI

The value of a predictive inventory system

Uncovering patterns in shifting demand and preempting the impact of anomalies is sometimes referred to as probabilistic or predictive inventory. Utilizing a predictive inventory solution enables grocers to understand ‘true inventory‘ by dissecting and connecting all the vast swathes of data and complex calculations that dictate whether they’re optimizing inventory levels.

KPIs such as reduced food waste, enhanced profitability, and greater replenishment accuracy are the key benefits of a predictive inventory system.

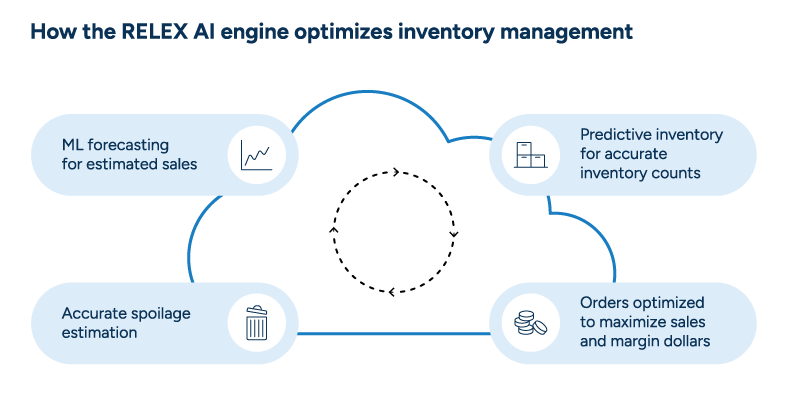

RELEX uses machine learning (trained on data from some of the largest grocery retailers in the world) to identify likely inventory miscounts. The system monitors sales data, looking for sudden drops in sales for items that should have on-hand inventory. It then recommends targeted inventory checks to store associates.

The sooner store associates identify a hidden stockout, the sooner they can correct it, feeding more accurate data into the machine learning algorithms. This continuous improvement of data reduces unstructured, labor-intensive inventory counts, freeing up associates for customer-facing tasks. More accurate balance data helps continuously refine forecasts to fit consumer demand and increase sales and profitability, which is particularly vital for fresh categories like produce and bakery items, where customers expect high quality and immediate availability.

Ultimately, these drivers lead to fewer empty shelves, continuous product availability while minimizing waste, and happy customers who experience both increased availability and improved sustainability.

RELEX True Inventory: Balancing demand and capacity in near real time

The RELEX True Inventory solution feeds on near real-time, historical, and trend data, applying that information on a granular level to how it will impact each product.

True Inventory’s power lies in analyzing data to uncover gaps between expected and actual demand, including data anomalies that could indicate hidden out-of-stocks. It then suggests targeted counts in stores to validate inventory figures or, for enhanced inventory, corrects those gaps based on the retailer’s data. This near real-time visibility is then translated into the best possible corrective actions that minimize waste, ensure availability, and have the greatest positive impact on sales.

RELEX’s Casey McSherry shares a brief overview of the True Inventory solution and how it drives inventory accuracy and order optimization.

This unified visibility and agility ensures that you never have to store items that are suddenly not needed in-store. It also creates a more seamless stock flow, with supply, demand, and internal capacity always aligned for each product.

This capability is critical for fresh produce in particular, with the impact of unforeseen events, slowdowns, or anomalies far more significant when expiration dates are much tighter. Avoiding spoilage and waste depends on being able to move inventory efficiently based on near real-time demand and capacity – not having too little stock that harms availability or too much that leads to either waste or smaller profits once pushed out at lower prices.

The end goal is to ensure that the right items are always in the right place, at the right time, and at the right price.

Essential capabilities for driving in-store inventory efficiency

Combating inaccuracies and the cycles of corrective decisions they create has compelling operational and competitive impacts. Implementing smart inventory management can transform how stores handle inaccuracy challenges through several key capabilities:

RELEX Mobile

RELEX Mobile supplies store employees with a single, easy-to-use tool for taking action on those recommendations and other tasks. Used in conjunction with RELEX True Inventory, it makes store operations more seamless and efficient by putting the power of smart inventory in the hands of store associates.

Casey explains how RELEX Mobile helps drive in-store efficiency and connects to the True Inventory solution.

Automated balance correction

Automated balance corrections reduce the need for manual checks, with adjustments made automatically to drive more accurate inventory figures while freeing up labor resources. The system also maintains a perpetual inventory from POS transactions, allowing sales to more directly impact replenishment, especially in fresh categories where demand changes can be frequent and sudden, and accurate inventory data may be less available.

Prioritization

While automating issue analysis is enormously helpful, it doesn’t work if current capabilities don’t align with the proposed solution. With a prioritization tool, each corrective action is made based on what’s needed and what’s possible at that time. Connecting inventory counting to business goals and capacity constraints to generate targeted recommendations decreases the strain on workers to manage on-shelf availability emergencies. It frees them to focus more on other tasks, making the entire inventory operation more efficient.

The RELEX journey

At RELEX, we know how challenging inventory management can be. Minor errors can have significant impacts, and when so many inaccuracies have become commonplace, it almost creates a norm where money is lost, workers become disillusioned, and customer loyalty is put at risk.

Our approach to smart inventory management unifies data across the full end-to-end supply chain. While other solutions may focus on only part of the retail ecosystem, RELEX’s ability to channel data from the store through the supply chain means you are constantly managing inventory according to what you are actually selling and what you are forecasted to sell moving forward. This predictive capability produces the best results when combined with a unified approach to the entire grocery operation – not just siloed stores or warehouses but the whole chain, end-to-end.

Real-world implementations have demonstrated remarkable results:

- 27% reduction in inventory balance errors

- Identification of 90% more hidden stockouts

- Sales improvements of up to 2%

- Significant enhancement in store efficiency through better labor allocation

Customer story: Ametller Origen

Spanish grocery chain Ametller Origen achieved a 10% increase in product availability while reducing inventory by 13% and spoilage by 30%. This success demonstrates how inventory optimization can simultaneously address multiple business objectives—reducing waste, optimizing labor, and boosting sales.

“RELEX’s smart replenishment solution has enabled us to significantly reduce our environmental impact through more efficient processes. The high quality of their demand forecasts has led to a reduction in fresh produce shrinkage, improving sustainability throughout our supply chain. We look forward to building on this strong start to continuously improve our sustainability efforts while improving key outcomes throughout our supply chain.”

Roberto Gómez, Chief Operations Officer of Ametller Origen.

Customer story: Wesco

Wesco, Inc., a family-owned and operated chain of convenience stores in the United States, selected RELEX to enhance operational efficiency and customer satisfaction by increasing product availability, optimizing inventory management, minimizing product spoilage, and implementing automation to empower both central and store-level employees. As part of their project, Wesco will adopt RELEX Mobile, which significantly enhances convenience retail operations by streamlining inventory management and reducing out-of-stock and spoilage, especially for perishable goods.

“We’re excited about rolling out RELEX’s integrated and unified planning tools across our 55 stores. This step is going to streamline our operations significantly, enhance our customer service, and empower our employees by optimizing our inventory management and reducing spoilage.”

George Barnhardt, Vice President of Revenue, Wesco.

Unifying data across the supply chain for inventory success

From forecasting to space and assortment to pricing and promotions, RELEX solutions benefit from this connected flow of data, which informs each stage of the process. With the RELEX architecture, each phased solution brings you closer to a truly smart store and supply chain.

The future of grocery retail lies in this intelligent, integrated approach to inventory management. As consumer expectations continue to evolve and sustainability becomes increasingly critical, the ability to maintain accurate inventory while reducing waste will determine which retailers thrive and which struggle to survive.