The journey to data maturity: How grocery retailers deliver customer value amid market turbulence

Mar 26, 2025 • 11 min

Grocery faces its fair share of data challenges. Phantom inventory and manual counts hurt data accuracy, while inventory drift muddles planning decisions. The gap between on-shelf inventory levels and system records leads to store inefficiencies and poor availability that mar the customer experience and result in lost sales.

Even so, data inaccuracy sometimes paralyzes transformation projects. So many innovations are never adopted because companies feel tethered to their poor-quality data and think they can only move forward if their data is perfect.

Perfect data is not the goal. The goal is customer value – and you can deliver that value with smart data management tactics and technologies that make data useful, even if it’s not perfect.

The question retailers need to ask themselves is: “What changes can I make to how I handle my data that will materially improve the customer experience in the most efficient way?”

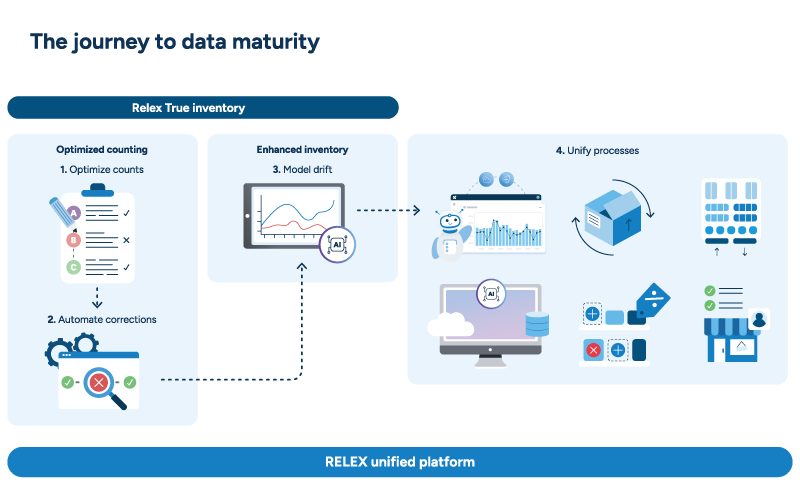

At RELEX, it’s a four-part journey:

- Optimize your in-store counting with targeted alerts.

- Automate inventory record corrections.

- Model inventory drift to reconcile ERP data to on-shelf availability.

- Unify data management across functions for cohesive, business-wide planning.

This approach allows retailers to track and analyze large swaths of data, prioritize exceptions that best serve the customer, and make efficient, cost-saving decisions that improve margins.

Every company’s journey will be different. The RELEX approach and platform allow companies to adopt a controlled, incremental approach to automation and AI implementation that aligns with business-specific needs, while delivering fast ROI that can fuel future transformations.

Let’s map out this journey and the tech implementations that support it.

A bird’s eye view of the journey toward data maturity

Our starting point is the RELEX True Inventory solution. True Inventory helps retailers enhance inventory accuracy for better store productivity and replenishment through two functions – Optimized Counting and Enhanced Inventory.

Optimized Counting powers the first two steps in the data maturity journey – optimization and automation. It generates inventory alerts, so store employees know what to count and when, prioritized by the impact on the business. It also helps retailers automate balance record corrections, reducing the strain on limited store-level resources.

The third step – modelling – falls under Enhanced Inventory, which uses sophisticated machine learning models to learn from past inventory behavior and other systematic factors. It recommends adjustments and autonomously corrects records to eliminate the gaps created over time by inventory drift, further reducing the need for labor-intensive manual counts.

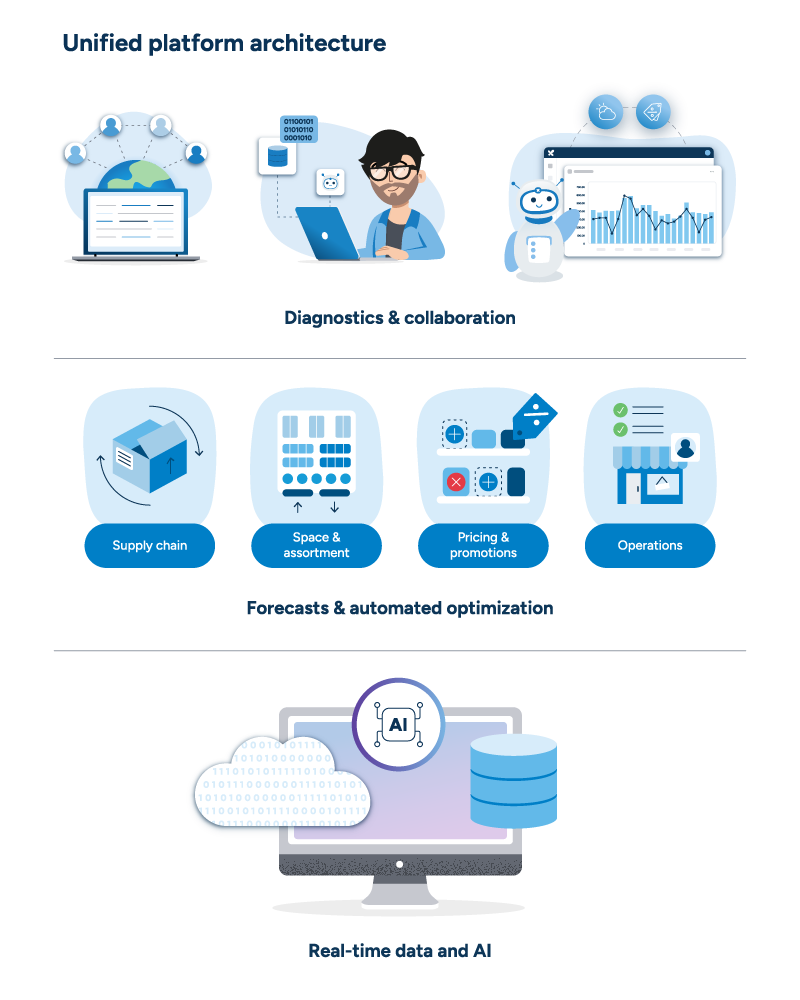

The final step toward data maturity is unified planning, achieved by integrating True Inventory with the rest of the RELEX unified platform – a suite of connected modules that share data, AI capabilities, diagnostics, and collaboration tools to balance and achieve cross-functional objectives.

Now that we have the basic map, let’s break down each step, examining the technology behind these capabilities and the role it plays in reducing the risks and uncertainty stemming from data inaccuracy.

Step 1: Improving store-level counting

We begin with True Inventory’s Optimized Counting capability, which helps retailers align their inventory with their data. It counters phantom inventory by assessing the likelihood and projected profit loss of a stockout and then sending store employees inventory count recommendations focused on at-risk items.

Optimized Counting is comprised of two probability-based mechanisms – anomaly detection and optimized scheduled counts.

Together, these mechanisms prioritize inventory tasks and decrease labor hours.

How anomaly detection works

Anomaly detection acts as an extra set of eyes, constantly surveying transaction data for discrepancies and alerting store employees to possible inaccuracies so they can check stock levels.

For example, the system might notice a sudden, abnormal decline in sales for an item that supposedly has on-hand inventory.

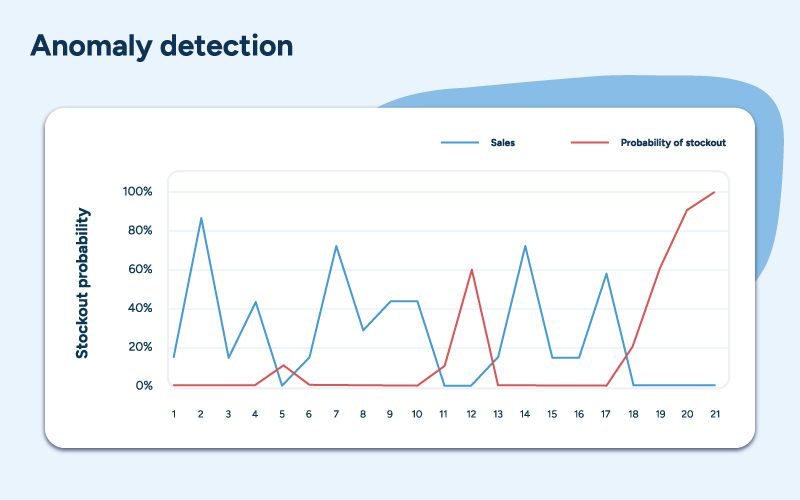

Take a look at the graph below. The blue line indicates sales numbers, and the orange line indicates the probability of a stockout.

On Day 18, sales suddenly drop to zero, a pattern that persists over the next few days. True Inventory recognizes that, given the continuing lack of sales, it’s becoming increasingly likely that the product is unavailable. Once a certain alert threshold is reached, the system recommends an inventory check.

RELEX will notice other unusual inventory behavior, such as ongoing sales for items with completely steady inventory levels or no balance at all. If a retailer triggers orders based on sales but always shows a lack of stock, there may be a deeper systemic issue.

By detecting problems automatically without waiting for scheduled counts or relying on random spot checks, anomaly detection gives store personnel a head start on possible inventory issues.

How to optimize count schedules

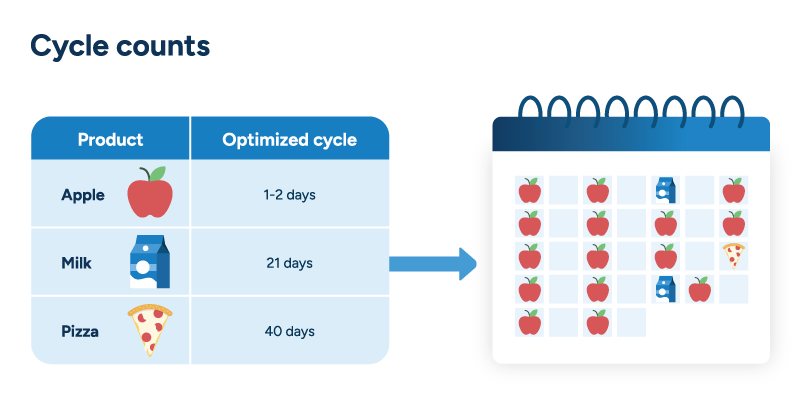

Inventory counts of products or product groups can vary widely in frequency and scope. Traditionally, these counts have followed arbitrary schedules that, at best, were only very loosely based on demand and spoilage estimates. In many cases, tech stacks cannot support a data-driven analysis of inventory behavior, making it difficult to optimize count schedules.

True Inventory calculates the optimal timing between counts, determining how long it takes inventory records to skew unacceptably from what is actually on the shelf. The system adjusts and optimizes schedules based on three inputs:

- Historical data accuracy (i.e., how quickly and severely data records deviated from reality in the past).

- Demand levels.

- Ordering parameters, such as batch size and delivery frequency.

By considering all three inputs, True Inventory recommends optimal counting schedules. For instance, a minor inaccuracy may minimally impact the bottom line depending on a product’s batch size and demand levels. On the other hand, in the case of fresh or fast-moving products, data inaccuracy may rise more quickly in proportion to an item’s sales or ordering parameters and, therefore, pose a bigger threat to sales and margins.

For example, the system might recommend counting the apple SKU at least every 3 days, milk every 21 days, and frozen pizza every 40 days, according to each item’s inventory behaviors and constraints.

True Inventory uses its comprehensive list of inputs to refine schedules and send count recommendations to stores on the appropriate day. By sending employees only the necessary count recommendations based on business impact, it protects availability while minimizing manual work.

Step 2: Letting automation handle inventory corrections

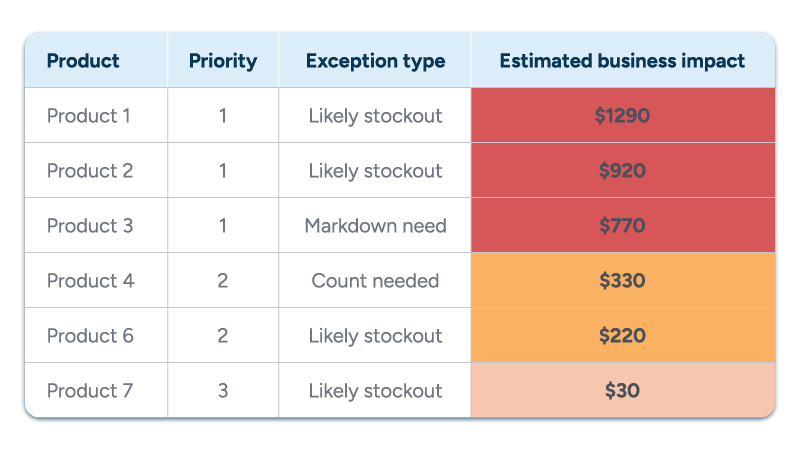

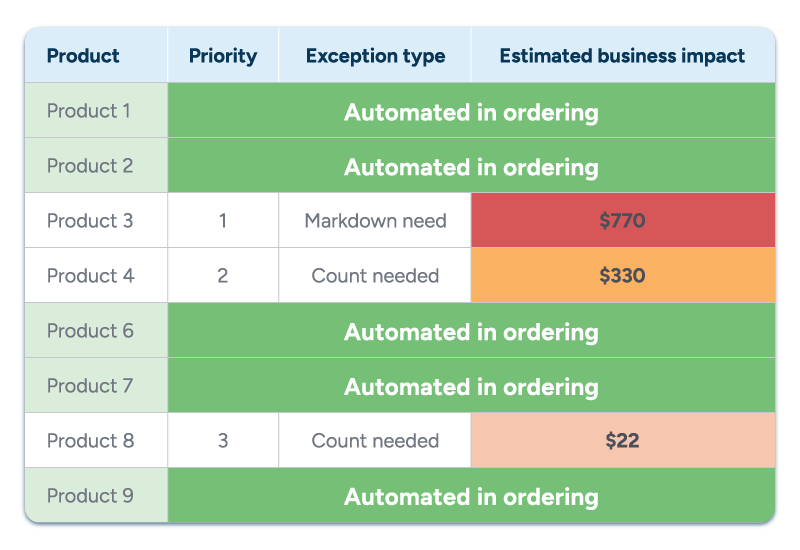

True Inventory’s Optimized Counting capability helps store associates improve their time management by focusing on high-impact products. A list of recommended inventory counts might look something like the graph below.

In generating this list, True Inventory opens up an avenue to greater automation. When the system detects a high likelihood of an alert or has a history of accurately identifying phantom inventory issues, it can automatically adjust the inventory records to zero and place a new order without manual intervention.

By increasing automation, retailers reduce the need for stock counts, minimize lost sales by catching anomalies sooner, and improve order accuracy.

Step 3: Modeling and curbing inventory drift

Let’s move on to the second step in our journey and the second capability housed in the True Inventory solution: Enhanced Inventory.

Enhanced Inventory uses machine learning (ML) to automatically identify and correct inventory errors and construct a digital perpetual inventory record that accounts for inventory drift and corrects balances.

Accurate balance counts help retailers:

- Improve order proposal calculations.

- Prevent lost sales and waste.

- Reduce the need for manual counting and ordering.

Eventually, automatically estimated inventory could exceed conventional data maintenance methods in accuracy, replacing the records in ERP systems and eliminating manual orders and counts entirely.

The brains behind Enhanced Inventory

RELEX uses AI and machine learning to detect systematic patterns from past inventory counts and other factors like spoilage, seasonality, and promotions to automatically “close the gap” between ERP data and physical inventory levels, thereby reducing ordering errors.

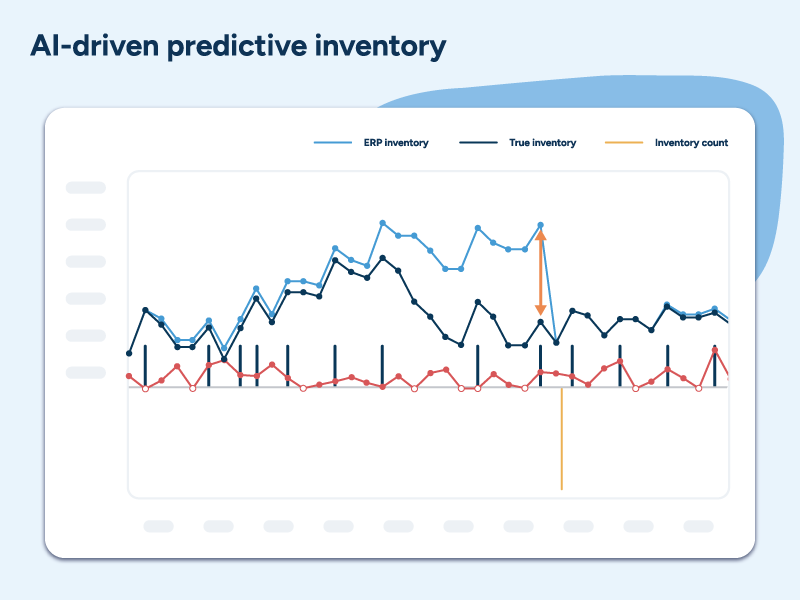

In the example below, we’re looking at the typical demand behavior of a fresh product, say, a tomato. The inventory drift accumulates rapidly, widening the gap between the actual inventory level and the ERP’s perpetual inventory record.

With each count, the True Inventory machine-learning model starts to track the drift. Once it has enough data points to calculate the difference between the ERP and the actual balance (depicted by the orange arrow), it converts that drift into an input for the algorithm. True Inventory then corrects the ERP record, bringing it down to align with physical balance levels.

Learn more: AI in supply chain

So, let’s fit True inventory into a retailer’s bigger plan for scalable AI-driven planning. Once you’ve achieved ROI from one AI implementation, like True Inventory, you can reinvest it in the next one.

But where to invest? How can companies maximize and scale those AI capabilities and data-driven benefits?

Step 4: Connecting and scaling with a unified platform

Siloed data, however accurate it may be, can cause errors across retail planning. Companies need to be able to disseminate, update, and use their data across all their planning functions.

That’s why RELEX built True Inventory into a unified platform that provides synchronized planning found nowhere else on the market. Its three-layer architecture combines a central data core, AI capabilities, interconnected planning modules, and diagnostic tools. Better quality data leads to better-performing AI and better business outcomes. This cohesive infrastructure allows companies to scale AI and optimize processes to drive customer-centric growth.

From inventory management to store operations, this unified solution:

- Reduces the burden of inventory counting for all product categories, from center-store items to fresh produce.

- Refreshes the shared data pool used by all store and supply chain planning functions for optimal decision-making.

- Requires no extra integrations or technology to sync data to replenishment capabilities.

- Provides multiple export options for stores, including RELEX Mobile Pro. Retailers can close the loop in one solution, via third-party apps, or through the retailer’s own application.

All of this is fueled by AI development that doesn’t stand still. RELEX invests up to 30% of its revenue back into its R&D functions. Good data means fine-tuned AI, and in turn, better AI analysis means cleaner data.

This R&D focus allows RELEX to deliver machine learning capabilities and AI innovations that can be seamlessly integrated into the platform as they become available. Customers never fall behind the latest tech developments, and their data, AI, and processes can all scale with them as their business grows.

The benefits: A win-win for customers and margins

Better data management is good news for the consumer. By integrating True Inventory and the RELEX unified platform, you can pinpoint what is most important to your customers and ensure availability, while helping store employees spend less time counting and more time focusing on customer service.

Plus, True Inventory implementation pilots have shown impressive results, reducing balance errors by at least 27% and identifying 90% more hidden stockouts compared to stores not using the solution. Customers could walk in, find what they need, and get on with their shopping.

Increased availability led to a 2% increase in sales – without a corresponding increase in spoilage. 2% may seem like a small percentage, but it scales across the board. For instance, the margin potential for a $10 billion retailer is $15 million, with total benefits (factoring in spoilage and efficiency improvements) racking up to $25 million. For a $100 billion retailer, that sales margin scales to $144 million, with a total financial payoff of $249 million. Annually.

One of those True Inventory customers who saw a 2% increase in sales value was Bünting, the German food wholesaler and retailer. The company also achieved a 43% reduction in balance errors on count days and a 1.6% improvement in product availability.

True Inventory helps retailers deliver on promises to their customers, keep their tech stacks strong, and improve KPIs like freshness, availability, and margins. This means you have room to grow, reinvest, and explore more products and more channels to better serve your customers and meet demand far into the future.

Taking the first step toward data-driven customer value

Widespread retail data inaccuracy leaves over $400 billion on the table. Conventional counting methods are no longer feasible approaches to data maintenance – but they’re also no longer the only approaches.

RELEX True Inventory breaks the cycle of inaccurate data with optimization, automation, and ML models that help retailers recapture lost sales, direct store personnel to high-impact exceptions, and generate reliable demand signals for accurate planning, ordering, and reporting.

Better data means greater efficiency, more accurate planning, and better value for your customers.

Learn more about gaining control of your data with RELEX True Inventory.