Regardless of industry, companies can’t escape the need – and difficulty – of finding a planning solution that can be easily customized and scaled. Most supply chain planning solutions on the market require extensive custom programming to fit a company’s processes and business goals. Typical customization requires changing the code of the software itself – a long, laborious, and expensive project that results in planning inefficiencies, fewer upgrades, and sluggish market responses.

Meanwhile, the knot of global supply chains is only growing, twisted by constant demand fluctuations. Companies must automate and optimize to keep up, especially as businesses expand and new products hit the market. Plus, normal shifts within a business can alter user roles and processes, requiring flexible rules and dashboards. Lacking configuration capabilities, typical solutions require outside consultation from the technology provider or partner, costing valuable time, resources, and money.

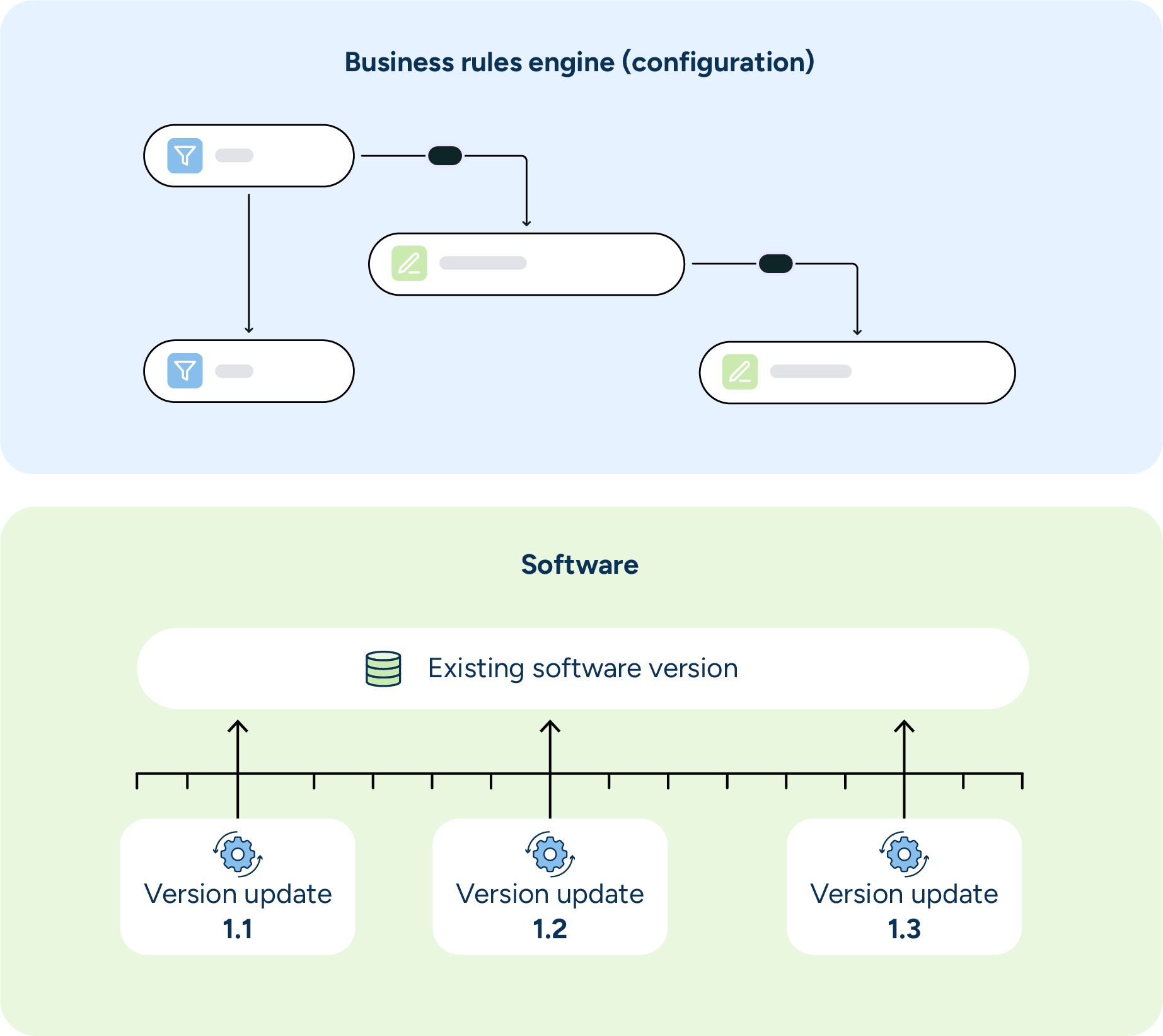

RELEX takes a unique “configure, don’t code” approach that allows companies to tailor their solutions without the cost and time that software development projects normally require. Configuration does not involve changes to the software itself at the code level. Instead, our configurable platform has a built-in customization layer that can be easily accessed via our business rules engine (BRE) – no coding required. The BRE interface hands our customers the power to modify their solutions in-house so teams can configure, upgrade, and scale at market pace and with minimal cost.

What is the RELEX business rules engine?

A business rules engine is a tool that allows users to automate processes and manage decisions by setting or selecting predefined rules, even if they have no technical background.

The RELEX business rules engine is the foundation of our “configure, don’t code” approach. With the BRE, users can customize processes and automate rules that monitor supply chain performance and trigger strategic responses to recurring situations such as forecasting exceptions. The user interface makes it possible for our customers to control their decision criteria wholly independently and without external support for faster, less costly solution management.

Plus, the BRE keeps its rule-based workflows separate from the underlying software application, so companies can easily upgrade their solution, enjoying the latest software developments without disrupting their established configurations and business settings.

The benefits of the RELEX business rules engine

The RELEX BRE gives companies the autonomy to make necessary changes faster so they can solve planning conundrums and take advantage of sudden market opportunities. It also helps them automate the processes that differentiate them in the market.

These efficiencies drive immediate and long-term benefits.

- Easier, less costly customization: By empowering users and reducing overall manual work, the BRE minimizes the need for expensive external support to tailor the solution.

- Faster responses to the market: With quick configurability that powers better decisions, companies become more competitive, drive sales, and improve service levels and customer satisfaction.

- Scalability and longevity of investments: Smooth software upgrades and flexible configurations make it easy to adapt to changing business needs and integrate the latest innovations, ensuring peak solution performance and continued ROI. The library of business rules also supports large companies with regional and local process variations by maintaining a central repository of workflows while providing subsets for specific, localized needs.

- Solution ownership: By training a small, select team of users to handle business rules, the system eliminates coding needs, reduces configuration risks, and ensures in-house control of the solution. This reduces strain on IT experts and helps IT leaders allocate budget, time, and resources where they are most needed.

How to implement the BRE as part of an adaptable platform

RELEX has developed a methodical crawl-walk-run approach that can be adapted to each customer, ensuring choices made within the BRE are deliberate, strategic, effective, and maintainable. We remain involved in configurability at whatever level and for as long as a company requires, but here is the trajectory of many customer journeys.

During the implementation phase, RELEX configures all the fine-tuned automation required to kick-start go-live and ensure quick ROI. We train one or two members of the customer’s own team to be “super users” who can configure and adjust the business rules. RELEX provides plenty of training to help users get comfortable with the system while ensuring new business rules function as intended and deliver expected value.

During the continuous development stage, super users and the RELEX customer service team collaborate to deploy workflow changes quickly, as needed. RELEX also helps onboard new super users as teams expand or as roles change, stabilizing business performance and keeping the company on the path to full ownership.

Companies that assume full ownership drive the continuous development of business practices independently, using the BRE interface to innovate and iterate processes through completely new business rules.

Throughout this journey and as their skills develop, super users learn to:

- Automate execution of defined workflows, including issue resolutions.

- Tailor workflows to business needs.

- Develop process innovations themselves.

Execution: The building blocks of business rules

The RELEX business rules engine is accessed via the configuration window. This graphical user interface allows users to control, customize, and automate different workflows, batch runs, filters, and actions. It enables simple automation of tasks such as exception management, master data maintenance, and the fine-tuning of business logic.

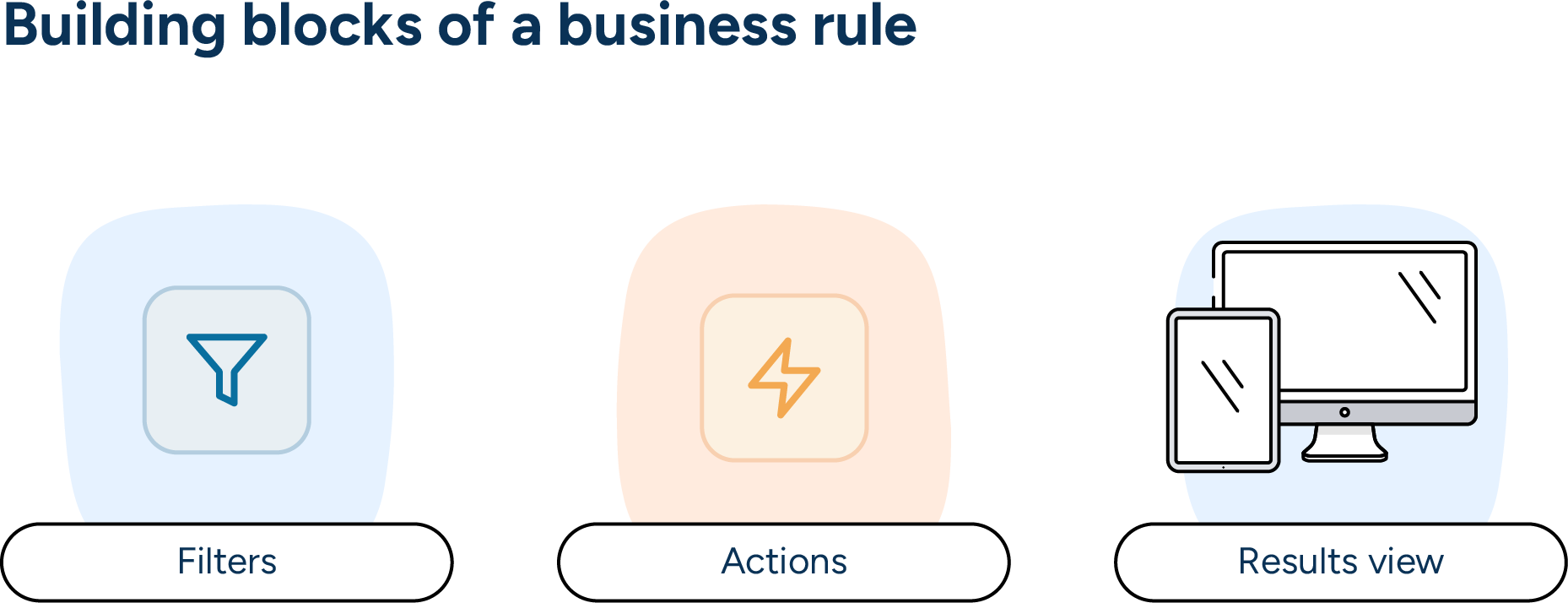

There are three fundamental components of a business rule workflow:

- Filters

Filters help determine search criteria, defining what data to include or exclude from the workflow, often according to product attributes, locations, or sales thresholds. By setting precise search criteria, users tailor workflows to include only relevant data for more accurate results. - Actions

Actions determine how the filtered data will be analyzed or processed. There are two different available processes.

– Users can set parameter values, dictating the workflow path the data will follow. Parameters typically involve inventory levels, order quantities, or forecast adjustments. By setting parameter values, users can dynamically update and control data based on predefined rules and conditions, ensuring that the system reflects the latest business logic and requirements.

– Users can execute actions by automating complex calculations and operational tasks, reducing manual intervention and enhancing overall efficiency. Actions often include calculating forecasts, optimizing order parameters, or executing allocations based on predefined rules and data inputs. - Results view

Once a business rule is set up, it must be tested. In the results view, users can control dimensions and values to improve reporting and assess workflow performance. Dimensions define how data is categorized and grouped, such as by product, location, or time. Values represent the actual data points or metrics, such as sales quantities or inventory levels. Results are then displayed in a multi-dimensional view that provides informative, actionable insights for better decision-making.

The results view is vital to the workflow testing process. It ensures that a business rule works as expected and delivers the desired outcome before it is applied to the live planning environment.

The user interface: Building a workflow

So what does this look like in practice?

Before we jump in, a quick note to remember before building a business rule: RELEX has a pool of experts and an entire repository of proven best practices that address common planning challenges.

You don’t have to reinvent the wheel. Take advantage of available templates and build up to more advanced configurations. You can even copy/paste existing workflows to create new ones, adjusting them to fit business needs without building everything from scratch. See the “Strategy” section for more guidelines about the thoughtful and practical use of the business rules engine.

Now let’s take it step by step.

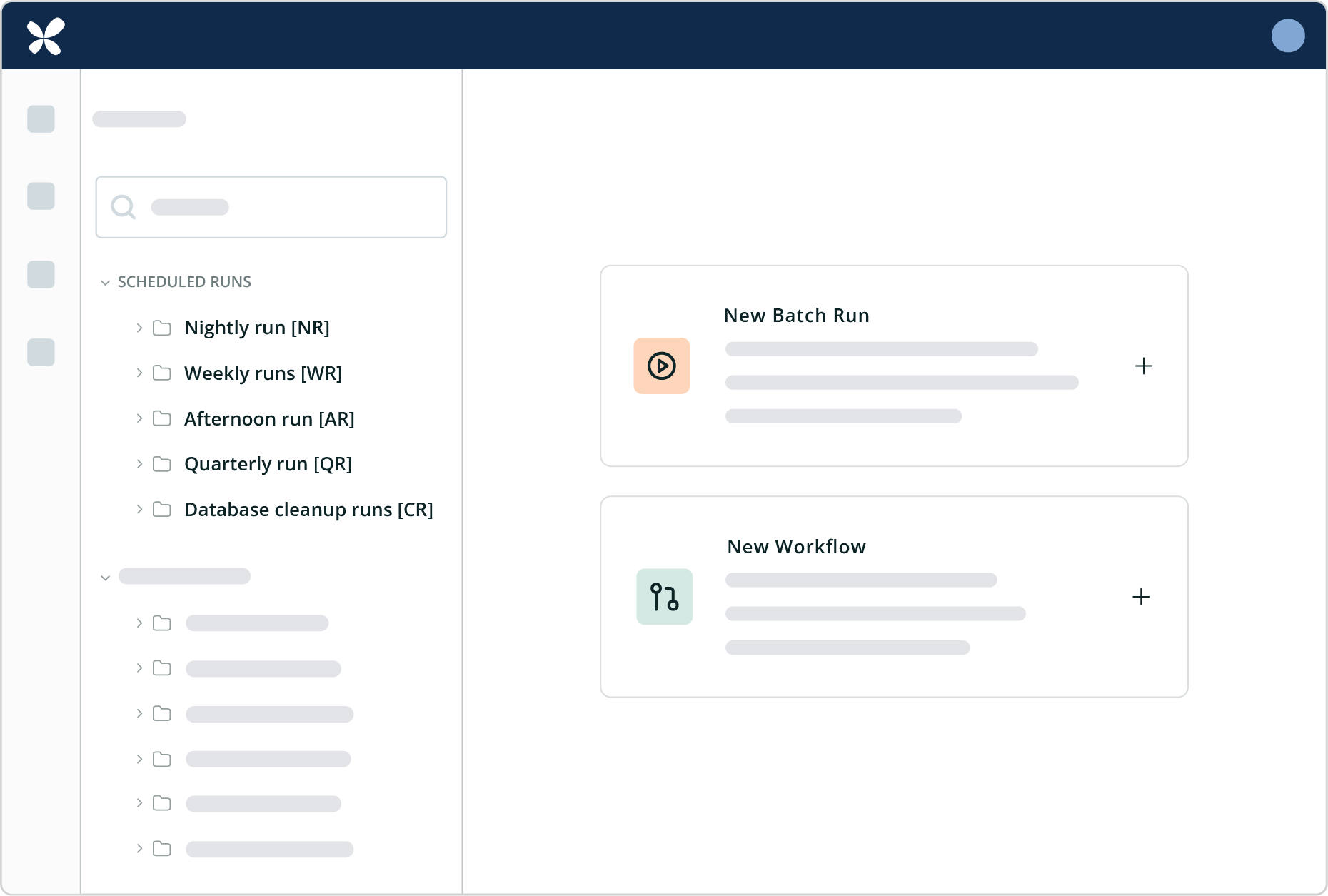

Step 1: Selecting a workflow

Business rules are built and viewed within the configuration window, which is accessed through a tab in the user interface. On the left-hand side of the configuration window, folders make it easy to group and maintain workflows and batch runs.

Workflows are a series of sequential, rules-driven actions that solve all or part of a specific business problem. They are often used to automate processes or optimize parameters.

Batch runs are widely used to run workflows and/or other batch runs in consecutive order, making sure the right processes and calculations happen in the right sequence at the right time.

For this example, a user can select a workflow from the list of folders.

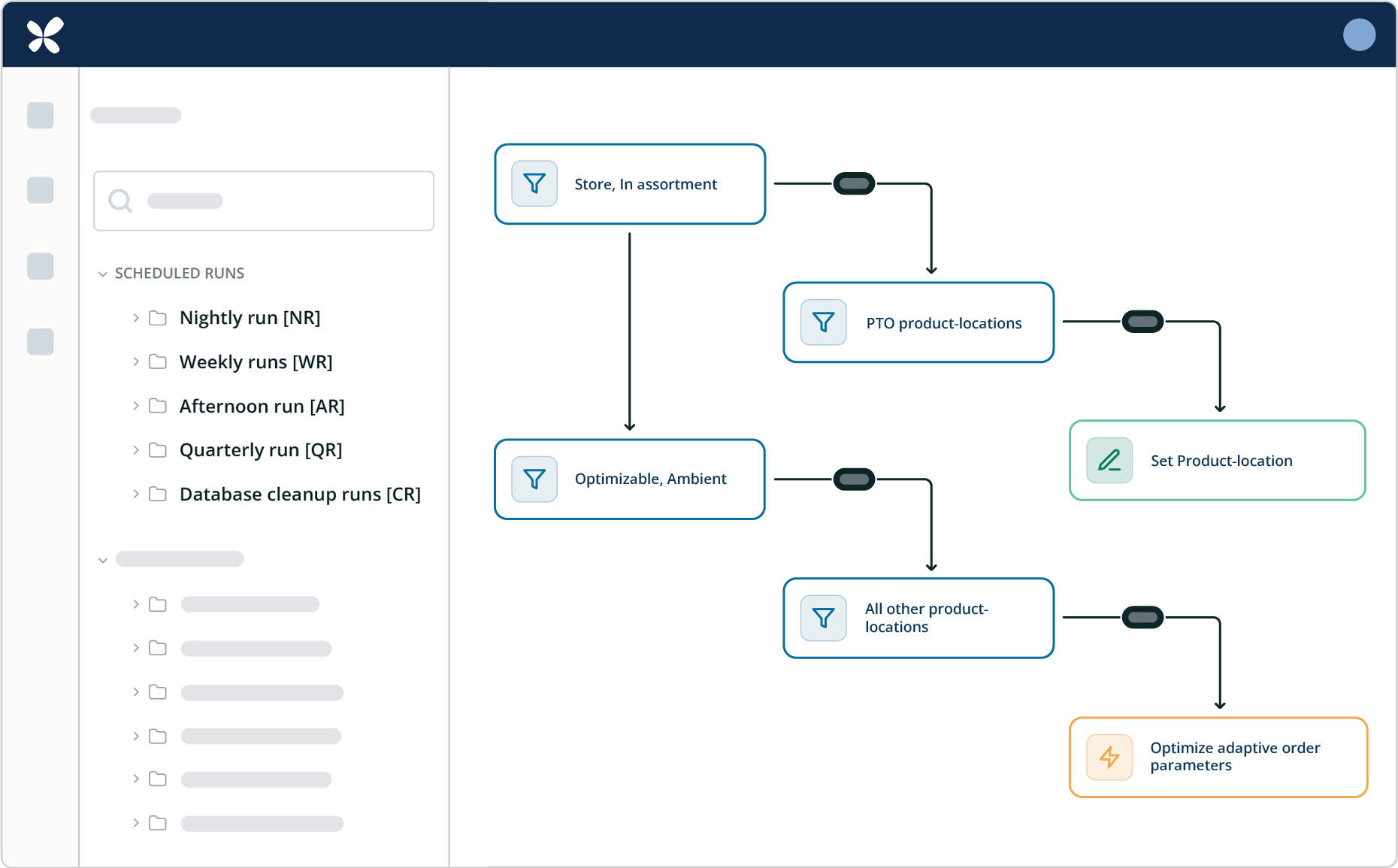

Step 2: Choosing filters and branches

Now we can start building filters and branches. Filters dictate what data will be included, and branches dictate the path that data will take toward a specific action, such as a calculation or optimization.

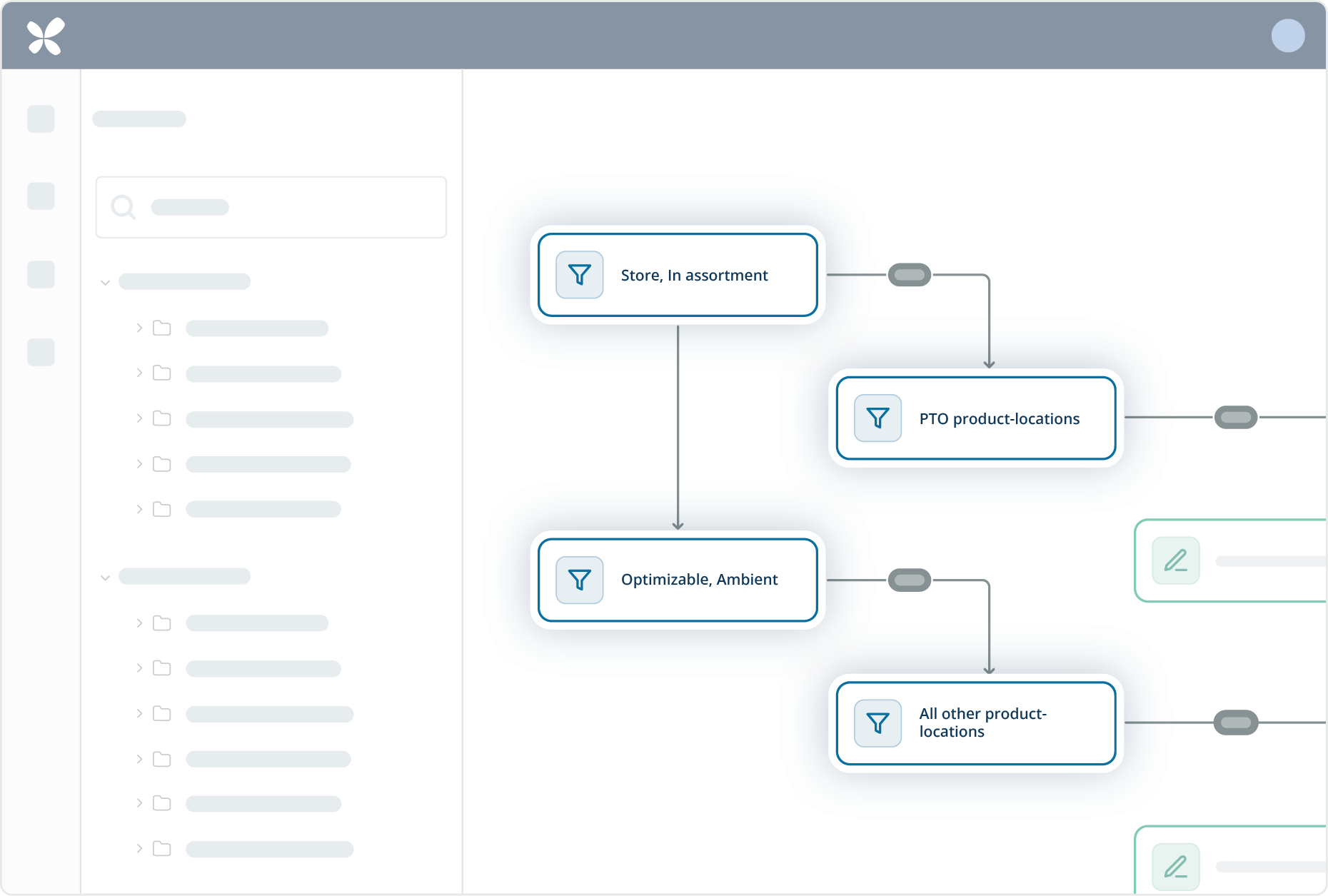

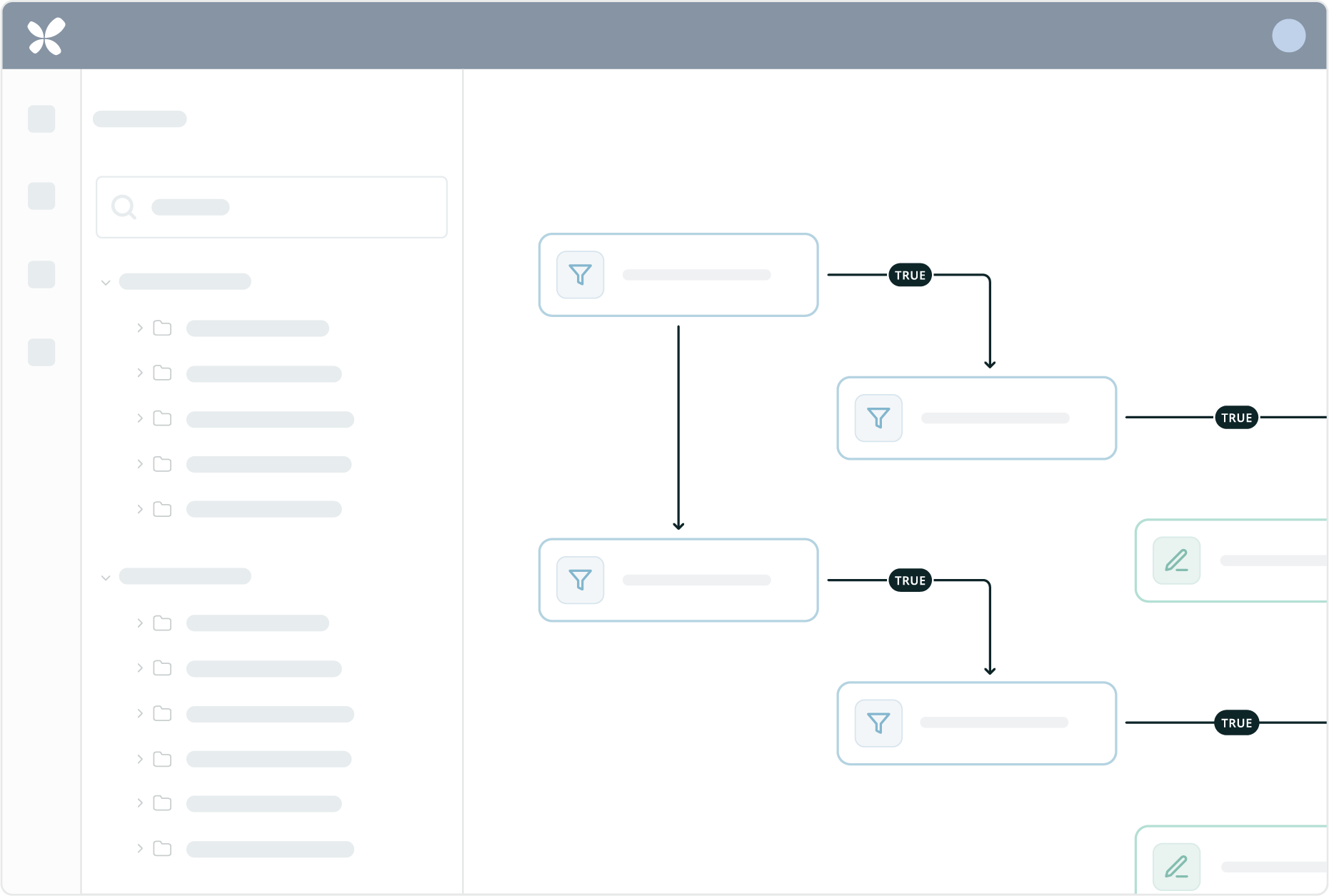

In the image below, filters (in blue) categorize the items, like products and locations, that will be included in the workflow.

Branches are used to direct the data. If an item matches the defined filter criteria, it branches to the right. If it does not, it branches down.

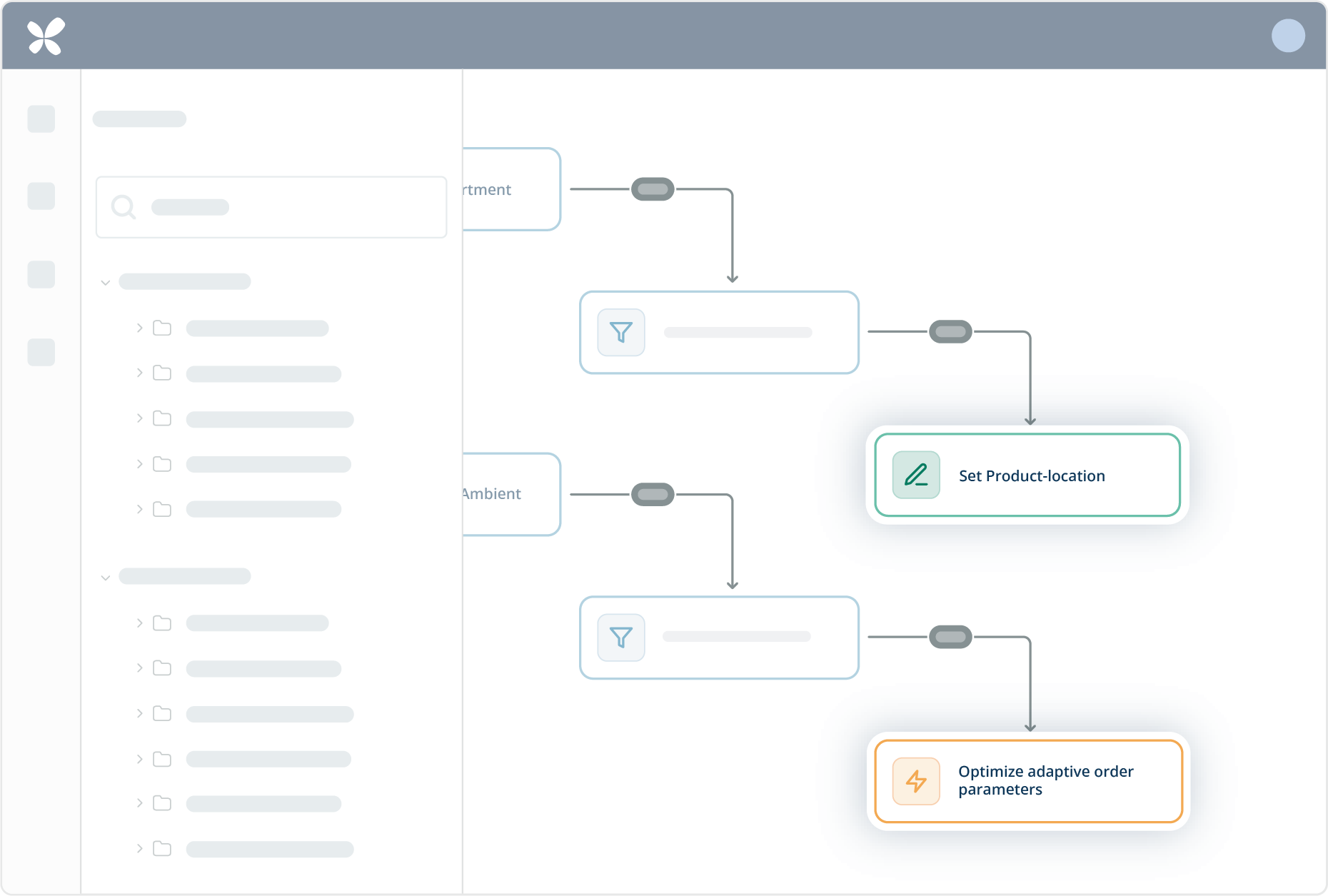

Step 3: Taking action

The final branch of a workflow ends with an action carried out on all data in that branch. Actions range from simply setting a value for parameters (in green) to more complex optimizations (in yellow).

A finished workflow might look something like this.

Once this workflow is automated, scheduled, or executed, users can see the results in a dashboard view.

Dashboards: Avoiding the “black box”

With all the data flowing in and out of the BRE, it’s important to make that data accessible, understandable, and actionable.

The BRE feeds into two types of dashboards.

- Reporting dashboards open what would otherwise be a “black box” system. They provide a presentational view of the data and workflows behind calculations. This visibility gives planners the data storytelling tools they need to highlight KPIs and communicate the impacts of business rules to different audiences.

- Operative dashboards, fitted with pre-approved workflows, allow users to trigger actions on an ad hoc basis for faster responses to market needs.

Real-world use cases

RELEX helps customers develop company-specific configurations year after year. Because we’re constantly documenting these developments, we notice patterns. Some configurations even make their way onto our standard list of business best practices.

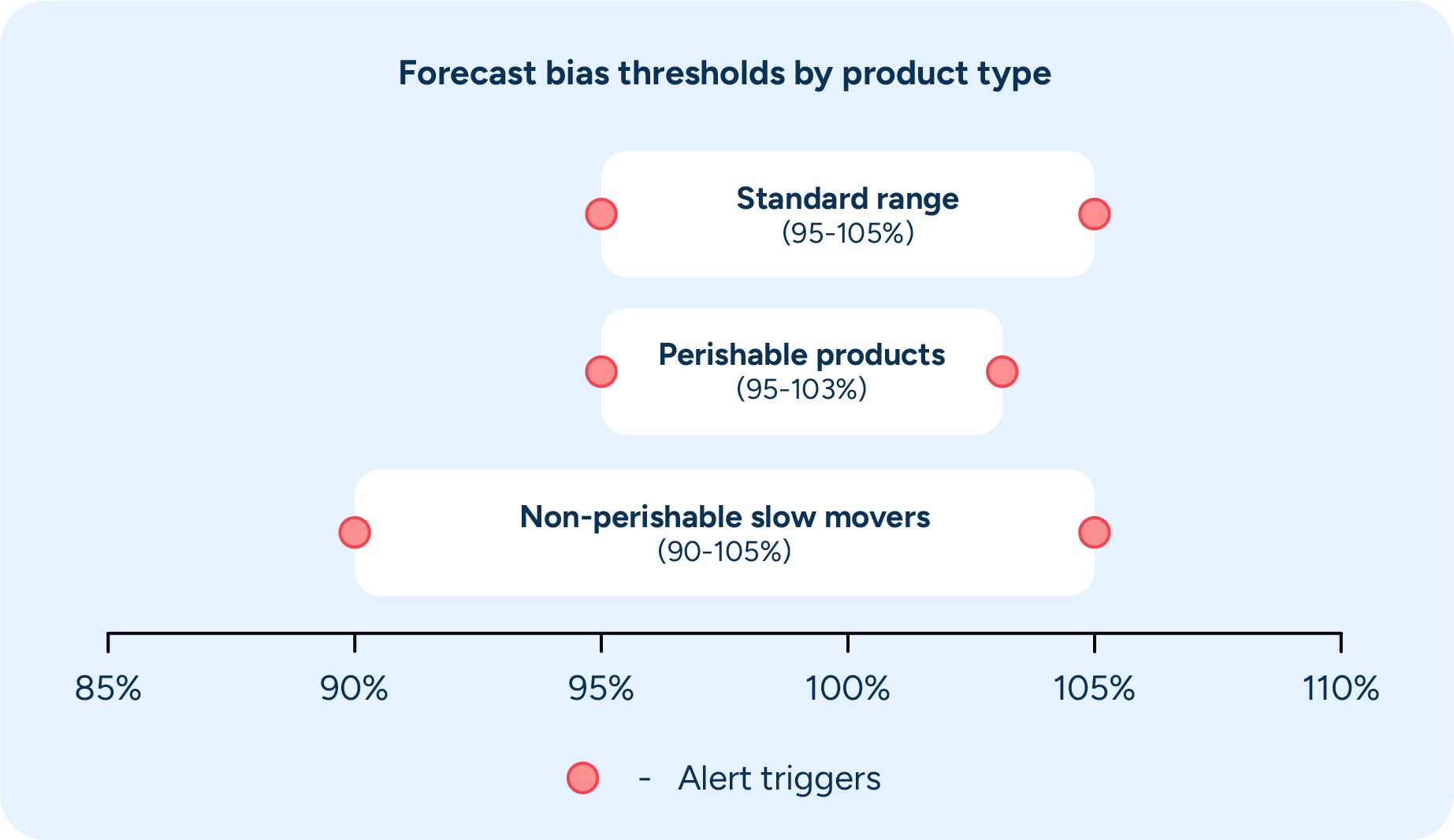

One of the simplest and most common configurations is the adjustment of standard forecast exceptions. Let’s say that, generally, a forecast bias between 95% and 105% for a store-level product is considered acceptable. Anything outside of this range is worth investigating. Using the business rules, these thresholds can be configured to trigger an exception review if the forecast bias for any product in the stores dips below 95% or exceeds 105%, alerting planners to the anomaly.

However, companies may want to set different thresholds for different products, depending on their industry. Using filters, a fast-moving consumer goods company or a grocery retailer can set much stricter overbias limits for perishable items, triggering alerts above 103% to get ahead of potential spoilage. Meanwhile, other industries with non-perishable, slow-moving items and different customer base expectations may be comfortable with an underbias threshold of 90%.

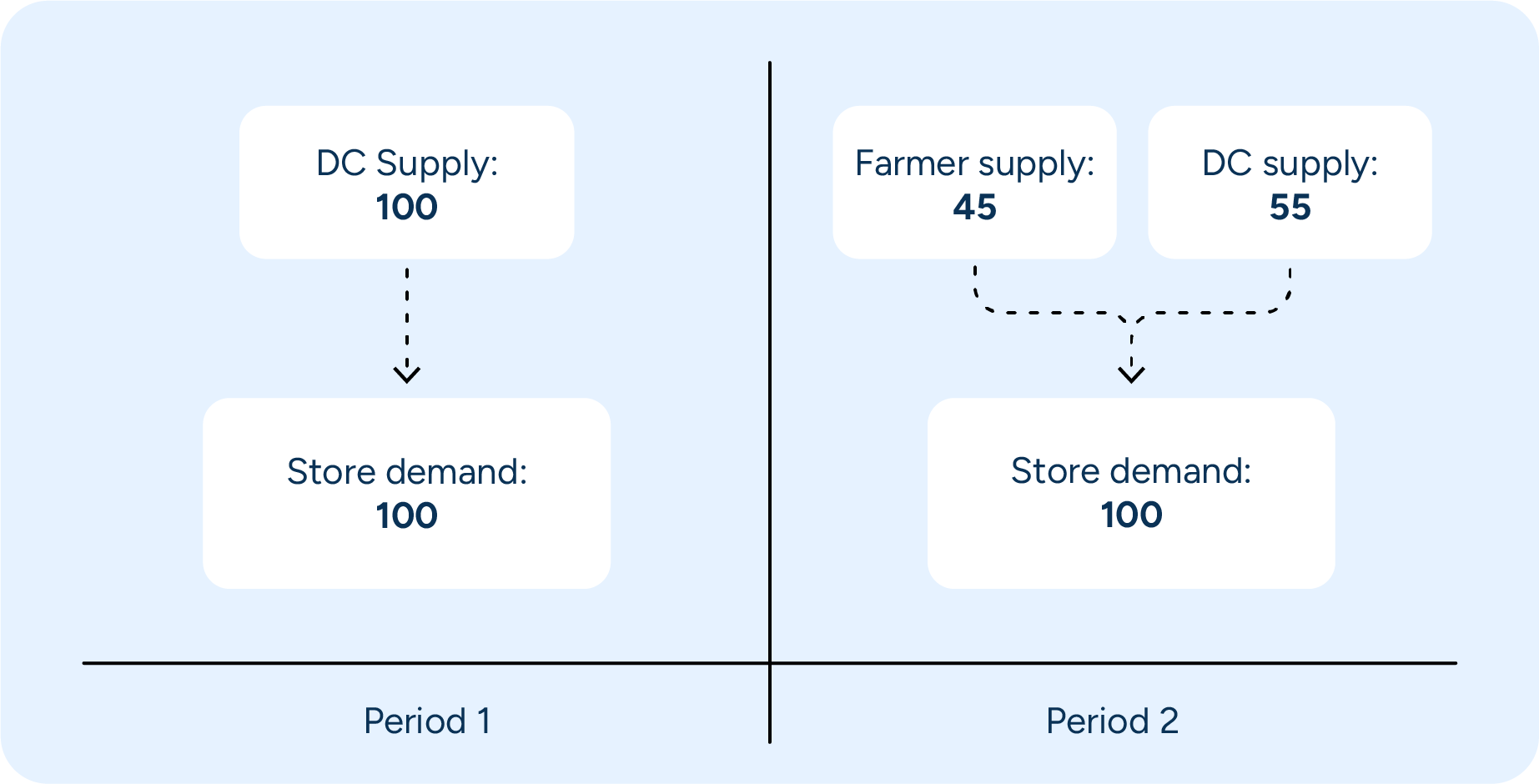

As another example, suppose that during certain times of the year, your stores manually order certain fresh produce from a local farmer instead of the usual distribution center. During these periods, planners must account for the expected drop in demand at the DC level while still fulfilling the same forecasted demand at the store level.

With the BRE, you can automate this process, calculating and accounting for the percentage drop in the forecast and appropriately dividing fulfillment between the farmer and the DC. In this way, you avoid costly overstock and spoilage while still meeting customer demand.

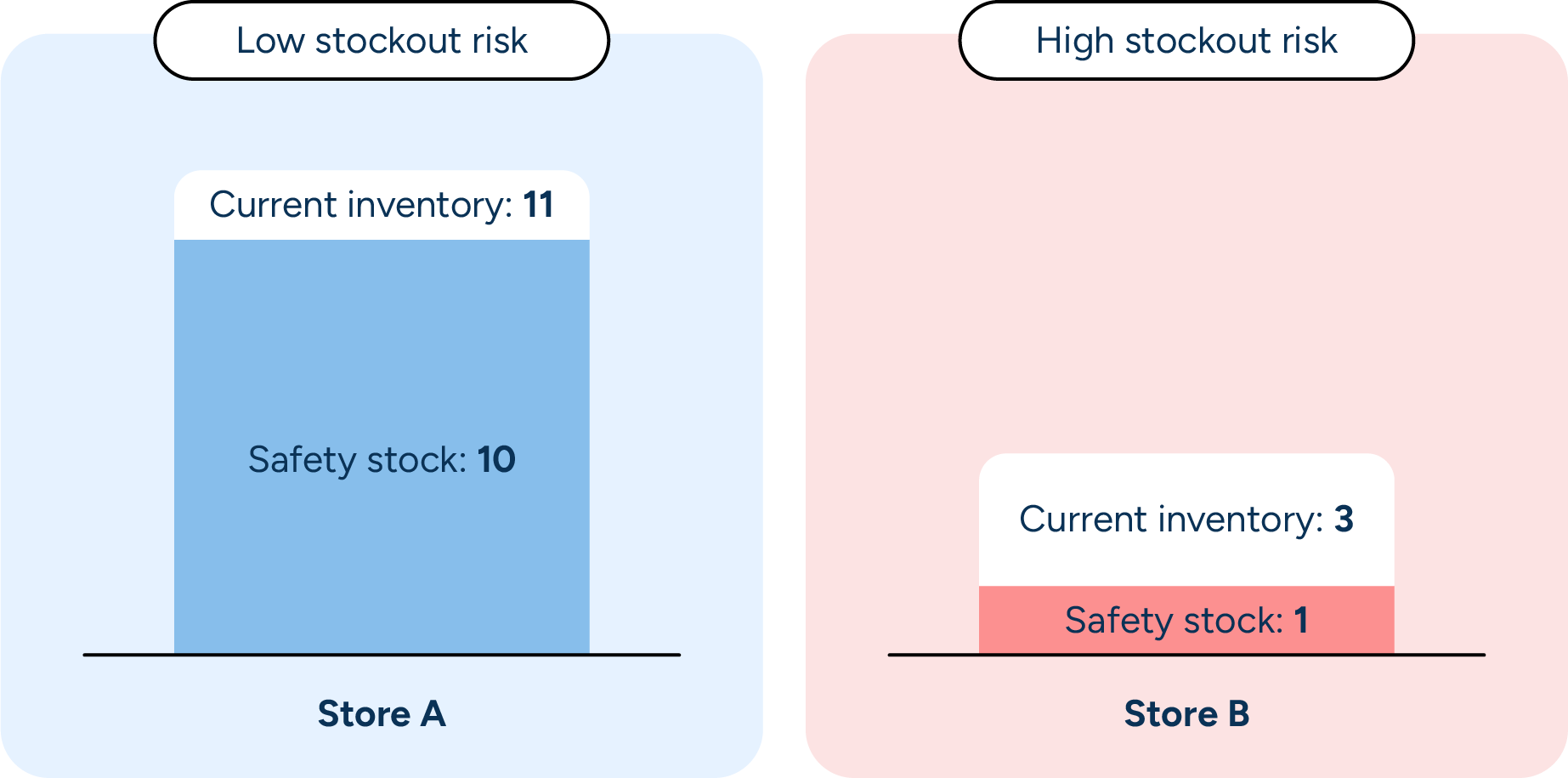

Perhaps you want to refine your scarcity allocation based on the risk of stockout rather than solely on the safety stock level so you can account for potential lost sales. For instance, let’s say Store A has 11 units of a particular product and a safety stock target of 10. Store B has three units with a safety stock target of one.

Although Store A is more at risk of falling below the safety stock target, Store B is more likely to face an actual stockout and lost sales. Refining the business rules that govern scarcity allocation allows planners to account for the actual business impacts, not just the standard inventory requirements.

You could also account for the impact of different forecasts. For instance, if Store A has a forecast of 100 during the shelf life of a product and Store B has a forecast of only 10, you’d want to prioritize Store A to minimize projected spoilage.

Strategy: Practical advice for making the BRE work for you

The use cases above illustrate how RELEX customers have used the business rules engine effectively. There are countless ways to customize, but there needs to be a business rationale behind every rule. Each one needs to make you more efficient and profitable or achieve a set strategic goal.

Here are some of our best practices for implementing a smart BRE strategy.

You need a vision

To guide innovation and keep development under control, identify specific objectives.

- What are the most important goals in the process?

- What are the KPI targets?

- Which KPIs take priority?

This is not a one-time discussion. Your business will evolve over time and so must your processes. You are not limited to answering these questions during the system’s design and implementation phase. In fact, it’s better to keep this conversation going while you monitor current supply chain performance.

Save only what works for you

At RELEX, we encourage customers to re-evaluate and improve their processes constantly. Save only those parts of your existing processes that make sense. You can easily create new ones where they don’t.

Keep in mind: Your old working practices may just reflect the constraints of your old tools. With the RELEX solution, you are no longer limited by those constraints, so think about what would best support your needs and strategy. We also have a 100% success rate for implementations and plenty of best practices to help you determine what works best for you.

Keep things simple

Always try to make the rules as simple as possible. Just because you can have a million interdependent rules doesn’t mean you should. Unnecessary complexity produces no gains but raises the risk of inefficiencies and miscommunication within your user team.

Have a development approval process in place

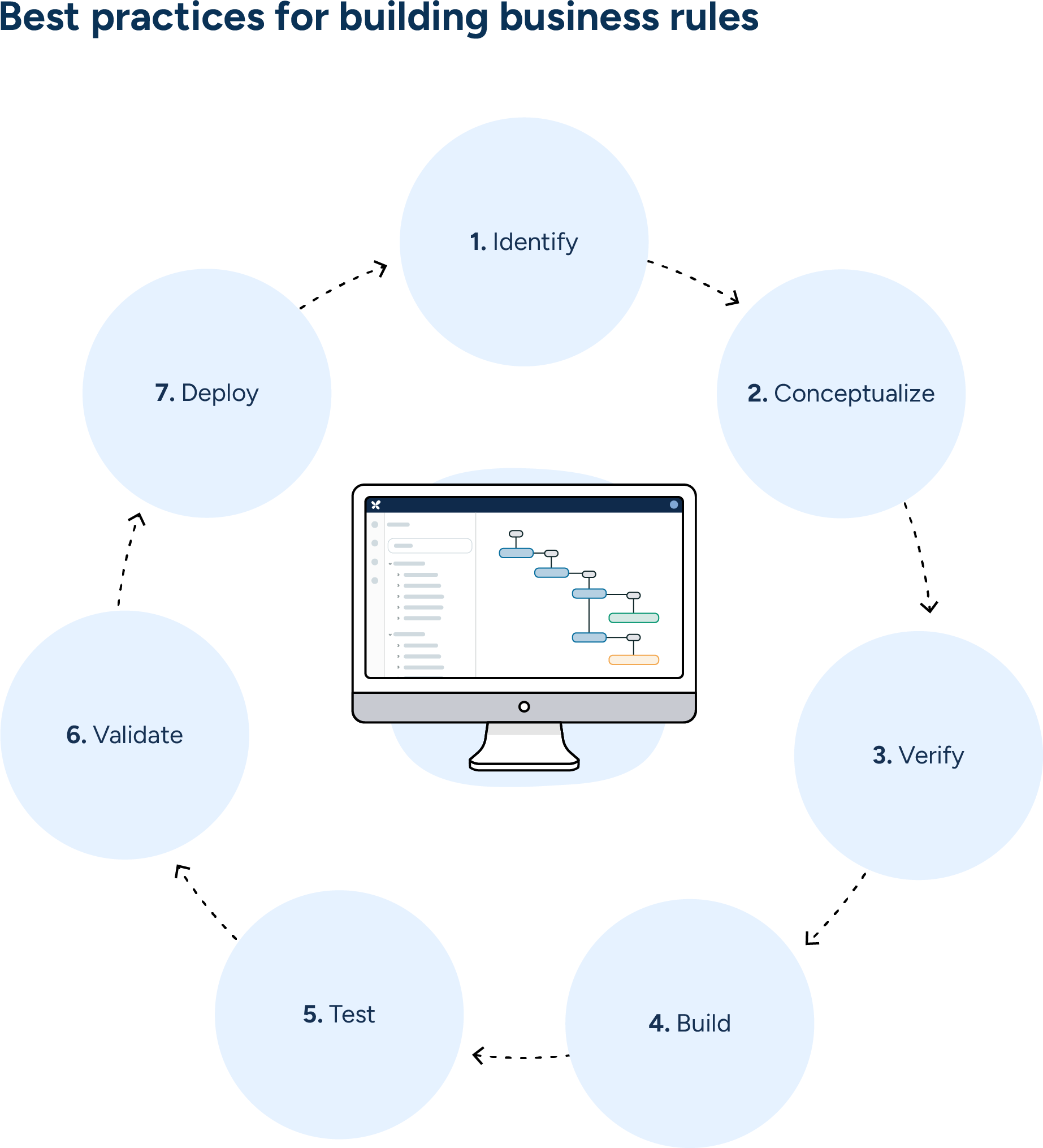

Growing teams and businesses need a development process that everyone understands. Although the number of super users may be limited, rules that will affect business-wide functions should be developed with input from various stakeholders and follow testing guidelines before being deployed.

- Identify the target: What are you trying to automate? What should be included in the scope?

- Conceptualize the idea: Consider the approach, consequences, and value of that automation. Is a business rule the best solution, or could it be solved another way? For example, perhaps you could solve a data issue through better maintenance instead of creating a workaround business rule. Balance effort versus outcome.

- Verify the idea: Seek internal and external feedback to unearth potential issues or concerns.

- Build the business rule: See if there are similar processes or best practices you could use first. Build the rule in stages. The larger and more complex the logic, the more necessary it is to break it into manageable pieces.

- Test the business rule: Test the workflow with clear expectations of the results, ensuring the process runs smoothly and produces output.

- Validate the results: Validate that the output provides the expected value.

- Deploy to production: Once the rule has been built, tested, and validated, transfer the rule to the live production planning environment.

By following a development process like this, teams can avoid business rules that compound planning issues and instead dedicate time and energy to rules that resolve inefficiencies.

How the BRE helps RELEX customers achieve KPIs

The RELEX business rules engine helps our customers improve operational efficiency, reduce waste, and widen margins through strategic automation.

Oda, Norway’s largest online grocery retailer, leveraged the RELEX business rules engine to automate and optimize their procurement and forecasting processes, leading to significant time savings and reduced food waste. The system’s adaptability proved crucial for Oda’s dynamic operations. “At Oda, flexibility is important because our needs change constantly due to the fast-paced nature of our business. Without a highly adaptable system, we would not have been able to keep up with the changes,” explained Logistics Developer Simon Svensson. “RELEX has allowed us to automate all our order proposals, drastically cutting down on manual processes. This automation has boosted our efficiency and significantly reduced food waste through more accurate and systematic ordering. Also, the ability to configure RELEX ourselves has been essential, enabling us to customize the system to our specific requirements without needing extensive coding knowledge.”

The ability to configure RELEX ourselves has been essential, enabling us to customize the system to our specific requirements without needing extensive coding knowledge.

Finsbury Food Group, a leading UK specialty bakery manufacturer, implemented RELEX during the pandemic to modernize its planning systems and optimize production. The business rules engine enabled quick updates to planning models, while AI-driven forecasting improved operations across divisions. The company achieved a £1.6 million reduction in working capital through smarter procurement and optimized safety stocks while improving service levels by 5%. The system doubled planner productivity and enhanced team collaboration while supporting the company’s IBP initiative.

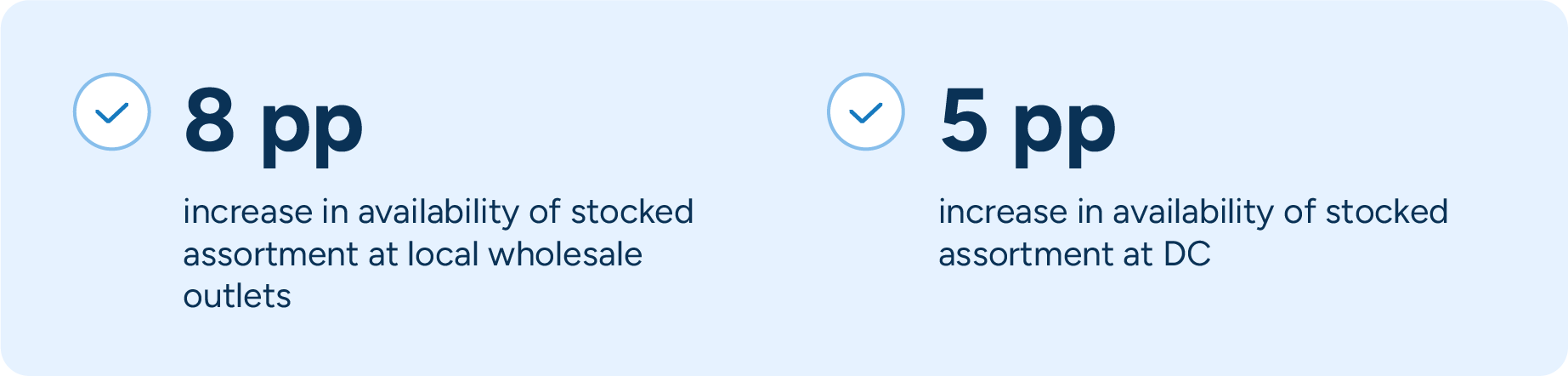

Örum, a Finnish automotive spare parts provider, implemented RELEX to centralize their replenishment operations. Örum used the BRE to manage their own modifications and adjustments independently, leading to improved supply chain transparency and more systematic replenishment processes across its network. The implementation increased availability at local wholesale outlets by 8pp and availability at the DC by 5pp. Automated order proposals based on accurate forecasts helped the replenishment team better manage slow-moving inventory and focus on customer service and handling exceptions.

How to build configurability into your supply chain

Self-serve configuration ensures scalability amid market change, but it’s only one part of the equation. When configurability is combined with innovative AI capabilities and unified data streams on one platform, businesses can customize their solutions quickly to deliver optimal results at scale. This integrated approach means that planning solutions can evolve as quickly as the companies using them, creating a sustainable framework for long-term success.