Managing uncertainty in demand forecasting: A pragmatic approach

Mar 21, 2025 • 9 min

Uncertainty is inherent in demand forecasting and can wreak havoc on retail operations — which is precisely why retailers prioritize managing these uncertainties effectively. But traditional forecasting methods often prove inadequate when faced with the volatile interplay between consumers and the broader market, and the resulting stockouts or excess inventory can seriously hurt retail operations.

Retailers have increasingly adopted more complex forecasting models in response to these challenges. These sophisticated forecasting models are useful and necessary for understanding and predicting demand, but the insights they provide need to be translated into straightforward, actionable recommendations for effective inventory ordering.

Managing uncertainty in demand forecasting shouldn’t overcomplicate planning and hinder the practical application of the data. Retailers should instead take a pragmatic approach that focuses on actionable insights and outcomes. Doing so requires a good deal of automation, an emphasis on the human touch, and software that incorporates them both.

What is uncertainty in demand forecasting?

Uncertainty in demand forecasting arises from the inherent unpredictability of consumer behavior and market dynamics. Retail demand is influenced by numerous variables. Some variables are predictable, such as seasonality. Others are more random or difficult to quantify. For example, a sudden change in weather can dramatically affect the sales of seasonal apparel, or an unexpected viral trend can spike demand for a particular product overnight.

In supply chain management, teams can estimate demand based on historical data and trends, but each prediction carries uncertainty. Various outcomes, from stockouts to overstock, can occur despite accurate forecasts, reflecting the inherent uncertainty managers must navigate in their pursuit of profitability.

The limitations of traditional single-point forecasts

Traditionally, retailers have commonly used single-point demand forecasts. These forecasts provide just that—a single point (or number) representing the expected demand value for a product. For example, such a forecast might predict that 100 units of an item will sell next week based on historical sales data, current market trends, seasonality, consumer behavior, and other relevant factors.

This method is simple and easy to communicate to stakeholders. Unfortunately, it doesn’t account for real-world demand variability. Factors such as unexpected weather changes, competitor promotions, or shifts in consumer preferences can result in sales that are significantly higher or lower than the forecast.

Overreliance on single-point forecasts often leads to suboptimal inventory decisions connected to exceptionally high or low demand. These decisions usually take one of two forms:

- Underestimating demand, resulting in stockouts, lost sales, and dissatisfied customers who may turn to competitors.

- Overestimating demand, leading to excess inventory, increased carrying costs, and potential waste, especially for perishable goods.

Single-point forecasts do not indicate the likelihood of these outcomes. Meanwhile, understanding the uncertainty allows for better decision-making, especially when retailers can use the cost of the adverse outcome as a weight in the process.

The limitations of single-point forecasts are especially painful considering just how commonplace the factors contributing to demand variability are. Weather changes day-to-day. Competitors run promotions constantly.

All the while, retailers make manual adjustments or rely on gut-instinct decisions to compensate for the shortcomings of their forecasts. These adjustments are often made on the ordering side, such as increasing safety stock or minimum fills, to mitigate some of the risks associated with demand variability. However, these stopgap solutions often lead to mixed results.

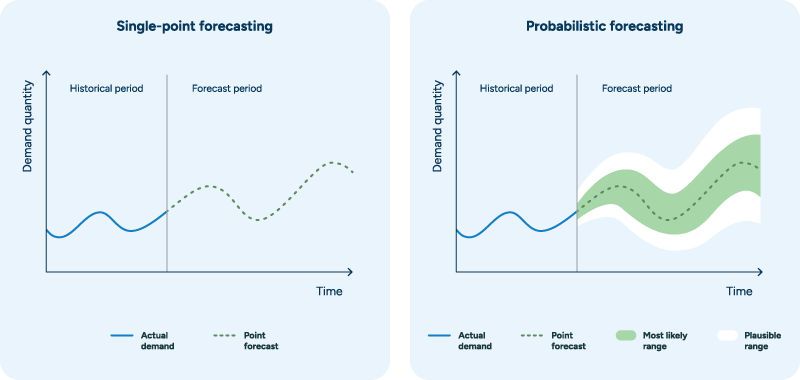

Probabilistic forecasting: From single points to distribution ranges

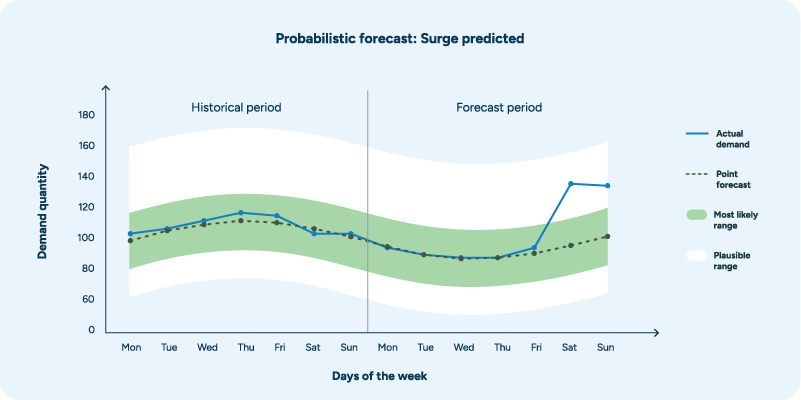

More recently, some industry experts have advocated for probabilistic forecasting methods to address the shortcomings of single-point forecasts. Instead of predicting a single demand figure, probabilistic models provide a range of possible outcomes along with their associated likelihoods. This approach can provide a more comprehensive understanding of potential future scenarios, aiding in better inventory planning and management.

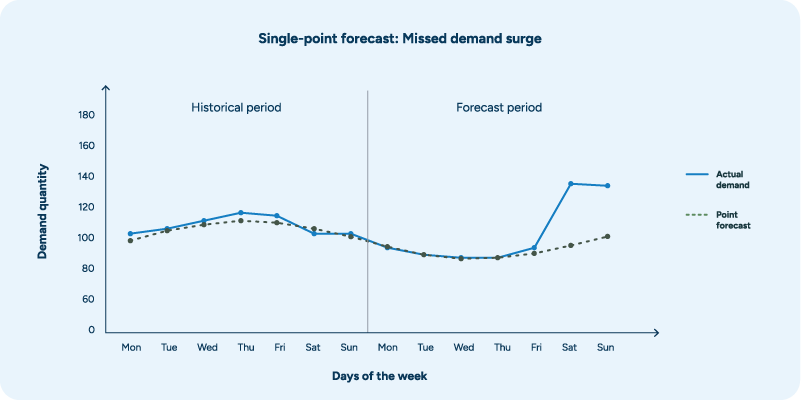

Consider this hypothetical scenario involving a fresh produce retailer. A single-point method based on historical sales data might forecast that the store will sell 100 units of cabbage over the weekend. But some unknown variable outside the realm of predictability drives a sudden surge in demand, leading to missed sales.

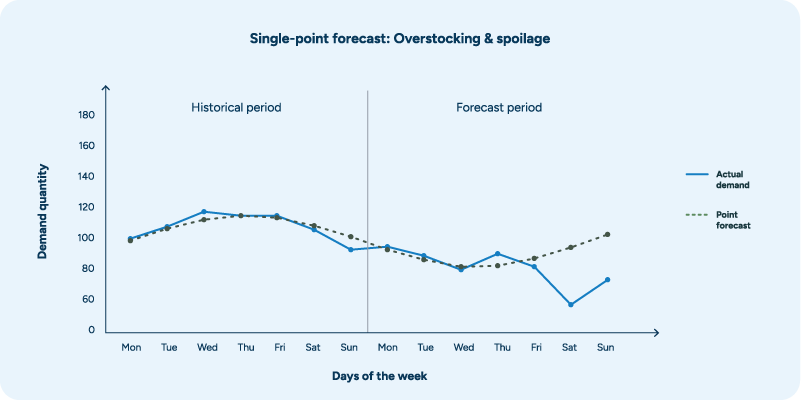

In an alternate scenario, an unknown variable could reduce demand dramatically, resulting in hundreds of unsold units.

In both scenarios, the single-point forecast didn’t account for the variability in demand, resulting in either stockouts or excess waste.

A probabilistic method would instead forecast a range of possible outcomes with associated probabilities. Anything that influences demand can also influence demand uncertainty, which means a probabilistic method would analyze various factors to create this range, including:

- Historical sales data.

- Seasonality and trends.

- Promotional activities.

- Price changes.

- Competitor actions.

- Macroeconomic factors.

In our cabbage example, an analysis of these factors might create a range of outcomes suggesting:

- A 20% chance that demand will be around 70 units— a lower demand scenario.

- A 50% chance that demand will be around 100 units —a normal demand scenario.

- A 30% chance that demand could reach 150 units — a higher demand scenario.

Understanding the full distribution of potential demand equips retailers with a comprehensive view of future scenarios, enabling them to make more informed decisions. Retailers can evaluate the likelihood of various outcomes and better assess risks to align inventory with projected sales volumes and reduce financial exposure.

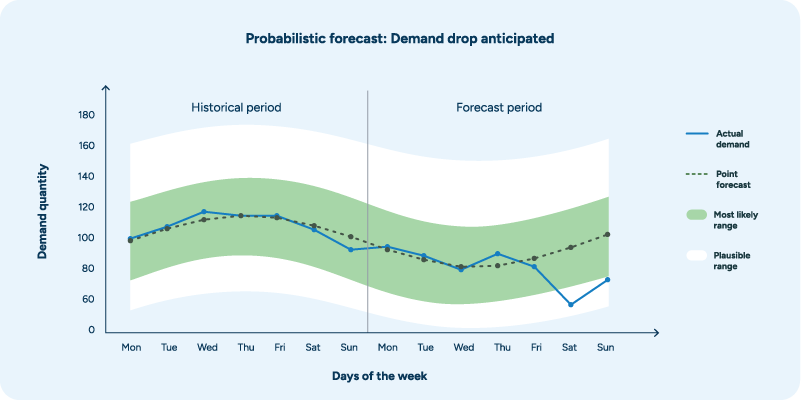

Figs. 4 and 5: Probabilistic forecasts account for a range of outcomes, allowing businesses to anticipate potential inventory challenges and adjust their strategies accordingly.

The downside of probabilistic forecasting

But sometimes, probabilistic forecasting is sophisticated to a fault.

The probabilistic method introduces unnecessary complexity into retail operations without proportional benefits in managing replenishment. The practical difference between too little and too much inventory for fast-moving items with long shelf lives provides enough cushion that simpler approaches work just as effectively. Retailers can often achieve optimal results for trickier items like perishables through more straightforward methods.

The complexity manifests twice: first in the forecasting models themselves and then in translating their outputs into practical ordering decisions. This added intricacy often obscures the path to better inventory management instead of clarifying it.

Many organizations require solutions that provide both advanced capabilities and meaningful user control over the optimization process.

What retailers need is an approach that balances sophisticated analysis with practical implementation — one that handles demand variability while remaining straightforward enough for planners to understand and actively manage. Some organizations may opt for fully automated probabilistic systems, but many others require solutions that provide both advanced capabilities and meaningful user control over the optimization process.

From dynamic safety stock to adaptive order parameters

Given the complexity involved, probabilistic forecasts work best for teams involved in mass decision-making, such as store ordering. They may say, “I’m going to fully automate the process, and I don’t want to understand every order.” But other organizations stand to benefit from an understanding and buy-in of automatic optimization and how a user can steer it toward the appropriate outcome.

Many retailers rely on dynamic safety stock, a concept that updates inventory buffers in near-real-time based on changes in demand. This typically involves setting safety stock levels in units of days, leading to a linear increase in buffer relative to demand, which can be prone to spikes and volatility.

RELEX offers a more advanced approach: adaptive order parameters. This methodology builds on the familiar foundation of safety stock while providing a more comprehensive, forward-looking framework for managing demand uncertainty. Adaptive order parameters use forward-looking estimated variance to create stable, predictable, and robust inventory buffers, allowing retailers to anticipate and prepare for demand variability more effectively.

Maintaining a strategic buffer of inventory to mitigate stockout risks isn’t a new concept, but past iterations have been decidedly low-tech, often relying on some combination of historical data, manual lead time calculation, and staff experience. These approaches weren’t resilient in the face of demand uncertainty and could easily result in inaccuracies and inefficiencies.

Adaptive order parameters take this concept to the next level with several enhancements:

- They optimize various order settings, including safety stock levels and must-order points.

- They are forward-looking, based on estimated future demand rather than historical sales data.

- They continuously adjust settings, reacting swiftly to changes in demand forecasts.

These capabilities allow retailers to anticipate and prepare for demand variability before it impacts their operations.

The power of predictive adaptation

Whereas traditional dynamic safety stock might simply increase inventory buffers in response to past demand spikes, adaptive order parameters take a more sophisticated approach by incorporating:

- Upcoming promotional activities and their predicted impact.

- Anticipated market shifts and seasonal transitions.

- Predicted forecast variance based on multiple factors.

- Real-time supply chain conditions and constraints.

This forward-looking perspective ensures that inventory parameters are optimized before demand variability has a chance to disrupt operations. The system continuously refines these parameters based on new data and changing conditions, providing a level of responsiveness that traditional approaches cannot match.

A focus on practical outcomes, not complex modeling

In most cases, retail decisions are made based on the overlap of two considerations:

- What’s the most profitable strategy…

- …that we can feasibly execute?

Adaptive order parameters excel at addressing both points by providing sophisticated optimization while maintaining operational simplicity. Instead of overwhelming users with complex probabilistic models, the system directly optimizes order parameters with precision, generating clear, actionable values that planners can easily understand. Users retain control through intuitive levers that allow them to guide the optimization in directions that align with their business needs.

The system directly optimizes order parameters with precision, generating clear, actionable values that planners can easily understand.

The real value lies in making decisions based on informed predictions, not in creating predictions themselves. This approach switches the focus from building and understanding predictions to using predictive insights for proactive and strategic inventory optimization.

The key to success: Incorporating automation and planner expertise

An outcome-centric approach to managing uncertainty in demand forecasting requires two essential components: a planning solution that automates the more labor-intensive, rote aspects of dynamic safety stock management and a team of experienced planners to make decisions requiring human judgement.

Embracing automation

Automated planning solutions handle tasks that are beyond human capability. They’re especially adept at processing large volumes of data in near-real-time. These tools can analyze historical sales data, track demand trends, and adjust safety stock levels faster and more accurately than any team of humans could possibly dream of. The result is a process that’s hyper-responsive and entirely automatic.

Automated systems can detect subtle changes in demand patterns that might not be immediately apparent to human analysts, adjusting safety stock accordingly before these trends can negatively impact the supply chain. This is particularly valuable in maintaining optimal inventory levels for products with high variability or in geographic regions where consumer behavior is erratic.

Valuing human judgement

Without automation, planners would be doomed to dedicate a substantial portion of their time to tedious, repetitive tasks associated with inventory management. Incorporating automation into the process liberates planners and enables them to focus on higher-level strategic activities that require human insight, such as:

- Crisis management and problem-solving.

- Complex market trends interpretation.

- Supplier relationship management.

- Ethical considerations and compliance.

Planning teams can also interpret the outputs from automated systems to make informed decisions. An automated solution might recommend increased safety stock based on anticipated promotional impact, but a human planner would take this a step further. The planner would assess the recommendation in the context of broader company strategy, competitive actions, and potential supply chain disruptions.

Managing uncertainty in demand forecasting with RELEX

At RELEX, we understand that the most sophisticated inventory optimization is only valuable if it’s practical to implement. Our adaptive order parameters approach empowers planning teams to influence and understand the process while automating complex calculations behind the scenes.

The RELEX solution enables planners to focus on three crucial planning elements:

- Guiding the optimization process for order parameters, including safety stock levels, replenishment frequencies, and order quantities through intuitive controls.

- Monitoring and responding to alerts for deviations from target inventory levels or other exceptions.

- Collaborating across functions to ensure alignment and address potential issues proactively.

This focus on practical solutions empowers planners to navigate the uncertainties inherent in demand forecasting. We ultimately want our users to take control of their inventory decisions, own their outcomes, and drive their businesses toward greater success. With RELEX, retailers can do just that.