Unlocking retail efficiency: How AI reduces cost of shelving

Apr 23, 2024 • 4 min

AI-driven shelving optimization can cut stocking work by 20% for retailers.

Store staff are essential sales and cost drivers in physical retail. In grocery, store labor is the most significant operating cost, amounting to around 14% of revenue. Optimizing these costs drives direct improvements to retailers’ bottom lines. Therefore, it is always good business for retailers to improve work efficiency in their stores. As retailers struggle with high turnover and a constant shortage of store workers, in-store productivity is more important than ever.

Store replenishment directly impacts operational efficiency in stores. Poorly planned store replenishment leads to inefficient shelf stocking in the stores, where streamlined operations ensure staff can dedicate more time to customer service and other value-added activities. In the worst cases, store workers spend a lot of time moving pallets around the store while stocking shelves and have to make frequent trips to and from the backroom storage area to fetch products.

In this article, we introduce the concept of shelving optimization and show how its application substantially improves in-store productivity. Moreover, we demonstrate how using AI (artificial intelligence) to optimize shelving work enables more efficient inventory flows in retail distribution.

Shelving optimization for more efficient store operations

Most replenishment systems base their planning on these distribution schedules. If daily deliveries are available, most systems will calculate orders based on next-day delivery.

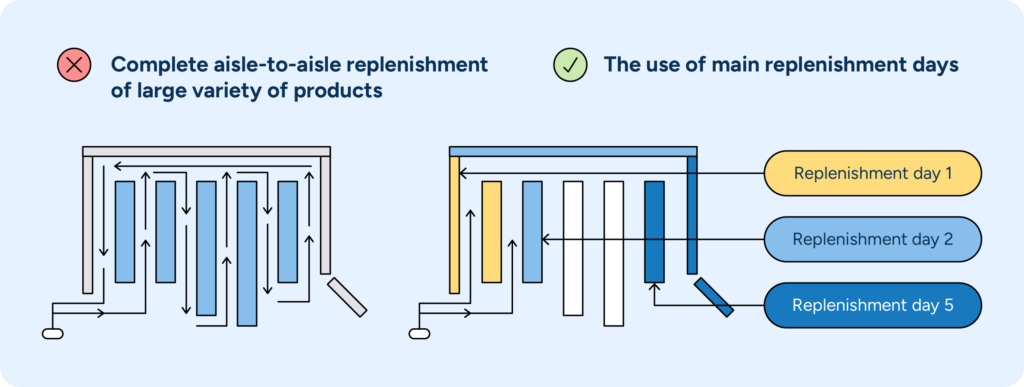

Yet, if all replenishment opportunities are used for all products without discretion, two problems follow:

- Pallets or roll cages delivered to the stores carry a random mix of products representing many different product categories located in other parts of the store. This means store workers must spend a lot of time moving pallets around the store when stocking shelves.

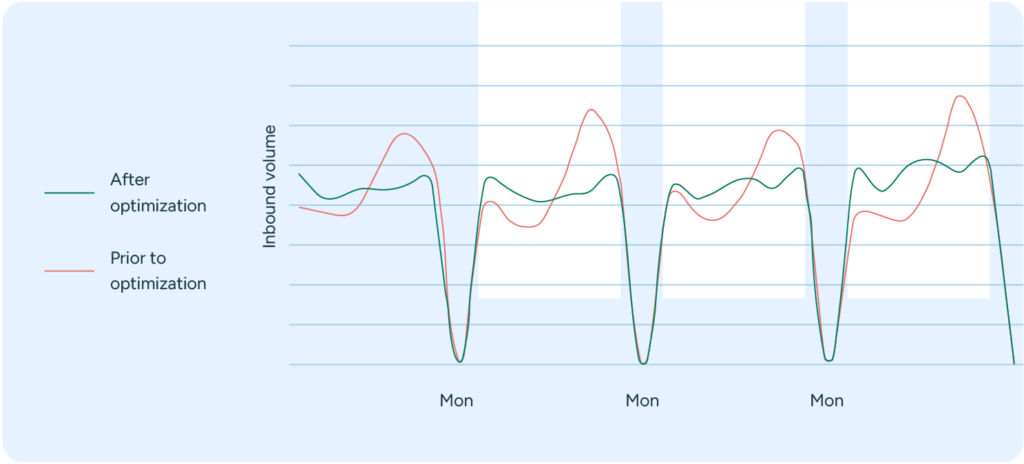

- The delivery volume to the stores reflects the stores’ daily variation in sales. Often, there are delivery peaks towards the end of the week in anticipation of weekend demand. This leads to fluctuating capacity needs in both distribution and stores, which, in turn, increases costs.

Strategic shelving optimization, by aligning product replenishment within specific store areas to designated weekdays, not only streamlines operations but also revolutionizes the efficiency of store personnel. This approach ensures that restocking is more straightforward and time-efficient, as products are organized and replenished by area. The system’s ability to adapt to unexpected demand spikes by placing additional orders further secures on-shelf availability, minimizing stock-outs and maximizing customer satisfaction. In practice, this means that not all products are ordered every day — for example, detergents. Instead, fast-moving detergents would be replenished on Mondays and Thursdays, while slow-moving detergents would be replenished only on Mondays. The other available replenishment days would be used only when stock-outs are risky.

Shelving optimization not only streamlines shelf stocking—significantly reducing labor hours—but also maintains, or even enhances, on-shelf availability, ensuring customers always find what they need. The complexity of optimizing shelving and replenishment schedules necessitates the use of AI, which automates planning and substantially improves outcomes. This leads to smoother inventory flows and more manageable workloads for store employees. Following the introduction of shelving optimization, we have observed a 20% reduction in the time spent on stocking shelves.

READ MORE: Unlock profitability with replenishment optimization

Artificial intelligence optimizes inventory flows

The RELEX shelving optimization AI algorithm uses a particle swarm algorithm for multi-objective optimization. In addition to shelving efficiency, the shelving optimization AI takes into account various factors such as inventory levels, product availability, spoilage, direct-to-shelf deliveries, and backroom stock. It aims to find an optimal balance within this complex landscape, ensuring that retailers do not compromise on their other business objectives while optimizing their shelving strategies.

AI handles the intricacy of planning for a typical retail store, which is too complex for humans to handle.

AI-driven optimization delivers clear additional benefits, including:

- A much smoother inbound goods flow to stores. This allows for more level workloads and more predictable work shifts in stores, increased cost-effectiveness, and significantly fewer capacity issues. In addition, a level base volume makes replenishment planning around major holidays easier.

- As artificial intelligence chooses the replenishment days more accurately, stores receive more of the same and similar products in one go. This makes in-store replenishment more efficient without sacrificing availability or straight-to-shelf deliveries.

- Optimization further decreases the number of store order lines. This means lower picking costs in the distribution centers as well as reduced handling costs in stores.

- The ability to plan ahead. With optimized supply chain planning tools, calculations can be made weeks in advance and project the outcome into the future, giving retailers time to react to changes.

Retail is undergoing a profound transformation, and only time will tell who the winners will be. In any case, it is evident that retailers can no longer afford to sustain inefficient operations. The ability to keep operational costs in check is essential for profitability and even survival. Applying AI-driven supply chain planning tools to optimize shelf stocking work and operations is an essential means to this end.