The wholesale industry hinges on efficiency. Any hiccup in the wholesale supply chain risks damaging customer relationships and ultimately a wholesaler’s bottom line. Unfortunately, efficiency has been hard to come by of late as wholesalers have struggled to manage the impacts of shortages, delays, and inflation-fueled cost increases.

The price of inefficiency is steep for wholesalers, who operate within razor-thin margins. Many wholesalers have turned to technological solutions to address their efficiency woes. They’ve embraced digital tools for forecasting and replenishment to realize higher inventory turnover, lower costs, and more satisfied customers.

Companies who optimize wholesale supply chain efficiency with data-informed digital solutions increase their value to suppliers and retailers alike, making such planning platforms essential to future success.

Key takeaways

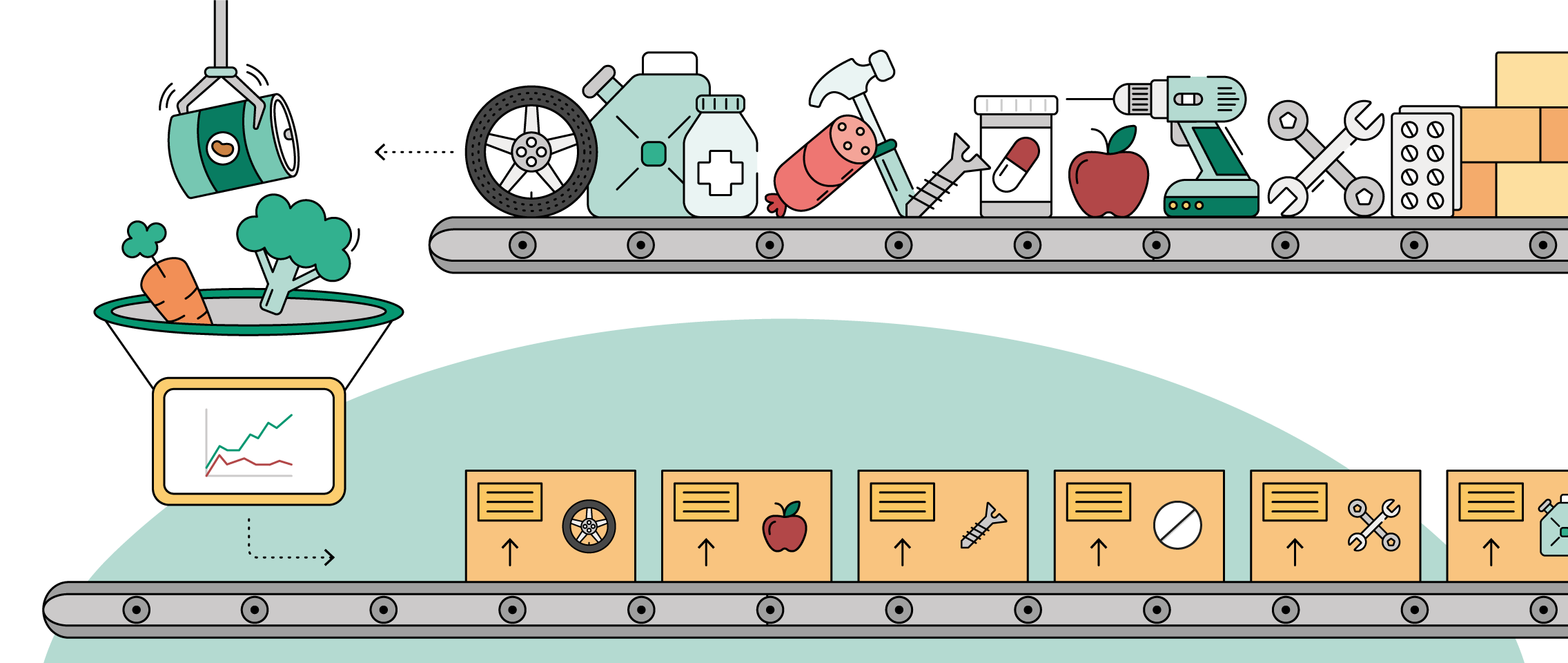

- Wholesalers act as the middlemen of the supply chain, purchasing a high volume of products from suppliers and selling them at low prices to retail customers and other businesses.

- The wholesale industry covers a wide range of verticals — including automotive parts and tools, building and construction goods, technical trade items, grocery and foodservice products, pharmaceuticals, and countless others — each with their own challenges.

- Wholesalers face many high-level supply chain management challenges, including shifting supplier and retail customer strategies, changing consumer preferences, external disruptions, and growing complexity.

- Wholesalers should embrace task automation, improve demand forecasting accuracy, and enhance supplier and retailer collaboration to increase margins.

- A robust supply chain planning platform is critical to improving wholesale supply chain efficiency.

What is the wholesale supply chain?

The wholesale supply chain refers to the system through which wholesalers procure goods from suppliers and distribute them to other businesses. Wholesalers purchase and store a high volume of products from suppliers, which simplifies supplier distribution and reduces their holding costs. These bulk purchases allow wholesalers to sell a smaller number of goods to retailers and other businesses at a lower price than the same volume purchased directly from the manufacturer.

Wholesalers act as the middlemen in the supply chain and assume sizable risk in this role. Suppliers and manufacturers sell in bulk at low prices in part because wholesalers assume carrying cost burdens. But carrying a vast volume of inventory that doesn’t quickly turn over often proves prohibitively expensive for wholesalers. And even small imbalances in on-hand supply and customer demand lead to the spoilage or expiration of fast-moving products.

Wholesalers vs. distributors

People often use the terms “wholesalers,” “distributors,” and “wholesale distributors” interchangeably. While distributors play a role similar to wholesalers, key differences distinguish the two types of businesses.

Distributors often hold contracts with manufacturer and supplier partners stipulating they can’t carry or promote rival products. They work closely with suppliers to promote these products to customers, effectively serving as an extension of the suppliers themselves. They sell to both wholesalers and directly to retailers in the supply chain.

Wholesalers buy from suppliers, manufacturers, and distributors. They have more freedom regarding what products they can carry and what they can promote. But because both wholesalers and distributors occupy “middleman” positions in the greater supply chain, they share similar concerns surrounding supply chain optimization.

Types of wholesalers

Much like the customers they serve, wholesalers come in all shapes and sizes — with every vertical experiencing unique issues.

Some of the largest wholesale verticals include:

Automotive parts and tools wholesalers

Wholesalers dealing in auto parts and tools manage a broad and complicated assortment. Their products often turn over slowly, forcing wholesalers to carry goods in limited quantities. Yet demand for the goods often shifts with the seasons, leading to undesirable stockouts and shortages caused by long lead times.

The fact that many auto parts and tools wholesalers are beholden to manual processes and archaic planning systems only compounds these issues. These companies require wholesale inventory management solutions that reduce inventory levels without sacrificing availability.

Building, construction, and technical trade wholesalers

Building, construction, and trade wholesalers are highly sensitive to seasonality, and external factors like weather can inhibit even the busiest of peak periods. Wholesalers in this sector must maintain high availability without overstocking — a task made more difficult by varying lead times and a wide assortment comprising both fast- and slow-moving inventories.

Wholesalers that have yet to modernize their supply chain planning solutions often find that their manual systems negatively impact other areas of their business as well. Customer experience and sales levels suffer when employees must sink their time into labor-intensive planning tasks instead of focusing on customer-facing tasks.

Grocery & foodservice wholesalers

Grocery and foodservice wholesalers both face the unique challenge of dealing with products that risk spoilage or expiration if they don’t move fast. Wholesalers who specialize in foodservice sell exclusively food products to industries like restaurants, caterers, and hotels. Meanwhile, grocery wholesalers face the dual challenge of carrying quick-to-expire fresh products as well as more stable ambient foods like canned goods.

Balance is a key concern for fresh food wholesalers. Businesses must maintain high service levels to keep their customers, especially ahead of promotions and peak seasons. But everything from poor weather to bad harvests can negatively impact supply and demand. Wholesalers also need highly accurate forecasting to prevent spoilage caused by over-ordering.

Pharmaceuticals wholesalers

Wholesalers in the pharma sector deal with similar pressures as other types of wholesalers, like managing inventory holding costs and maintaining necessary service levels. But they must also meet restrictions, requirements, and regulations from retailers, pharmaceuticals suppliers, governments, and other regulatory bodies that affect when and how orders can be fulfilled.

Pharmaceutical wholesalers commonly see sudden demand shifts as they service a diverse customer base that includes hospitals, retailers, and other healthcare services. Product shortages on the part of suppliers exacerbate these supply and demand issues. Optimization of the pharmaceutical wholesale supply chain requires a forecasting and replenishment solution capable of swiftly detecting demand shifts and adjusting forecasts accordingly.

The benefits of wholesale supply chain optimization

There’s a classic “glass half empty/glass half full” way of looking at the wholesale supply chain. Glass half empty: wholesalers face challenges on both the supplier and retail customer sides of their supply chain. But glass half full: wholesalers have ample opportunity to improve efficiency on both the supplier and retail customer sides of the supply chain.

A streamlined supply chain provides cost-saving and value-adding benefits that are critical for long-term success.

Wholesalers must solidify their position and raise profit margins to thrive in a complex, ever-changing market. A streamlined supply chain does just that, providing cost-saving and value-adding benefits critical for long-term success.

These benefits include:

- Increased inventory turnover. Wholesalers who work from highly accurate forecasts manage inventory more efficiently, reducing holding costs and spoilage due to overstocking.

- Decreased complexity. Inventory may ship from the manufacturer to a central wholesale location and then to regional branches before reaching stores and consumers. Wholesalers working from the most up-to-date forecasts and working from data-informed digital models maintain better supply chain visibility and control even as the business scales.

- Increased productivity. Too many highly trained workers get mired in repetitive background tasks instead of focusing on revenue-building tasks. Wholesalers who use digital tools to automate tedious tasks like manual forecasting can instead turn skilled employees toward nuanced, value-adding work that computers can’t perform.

- Improved customer satisfaction. Retailers often feel the biggest impact of disruptions, given their position at the end of the supply chain. Any wholesaler who can fulfill orders on time and at a low price is sure to thrill their retail customers.

3 biggest wholesale supply chain management challenges

Wholesalers of all varieties face multiple high-level challenges that complicate the supply chain and threaten profitability. The three biggest supply chain challenges facing the wholesale industry include:

1. Increasing external disruptions

The onset of the COVID pandemic revealed gaping inefficiencies in the whole value chain. Suppliers, manufacturers, wholesalers, retailers, and consumers alike still suffer from material shortages, delivery delays, and sky-high inflation. These disruptions are lose-lose situations for wholesalers, who try to appease manufacturers and customers alike while stuck in the middle of a hobbled supply chain.

Wholesale business models only succeed within razor-thin margins, and these companies have seen margins erode from both ends of the supply chain. Wholesalers pay more for products as material prices and inflation rates have risen. This puts wholesalers in the unfavorable position of passing price increases on to their retailers, many of whom are already signaling an unwillingness to raise prices further on their consumers.

Supply chain disruptions especially hurt wholesalers who deal with fresh products or those that expire quickly. Delayed shipping from suppliers or to retailers can result in spoilage and waste, resulting in lost revenue and unhappy customers.

2. Shifting supplier, retailer, and consumer preferences

Retailers tired of repeated disruptions have increasingly turned to vertical integration to take ownership of their supply chain. And more suppliers than ever have turned to direct-to-consumer strategies through new sales channels like ecommerce. These changes have chipped away at the middle ground wholesalers have traditionally occupied.

Sales of private label products grew by 11.3% in 2022 alone.

Consumer preferences are also shifting. Consumers are increasingly cost-conscious due to high inflation and look for high-quality, low-cost products wherever they can. This search for value has fueled an increase in the sale of private label goods. The Private Label Manufacturers Association reports that sales of private label products grew by 11.3% in 2022 alone, a trend which puts pressure on wholesalers to offer these goods to appeal to consumer needs.

3. Growing supply chain complexity

Changes in infrastructure, procedure, distribution, and customer expectations have complicated operations for every business within the supply chain. And wholesalers, manufacturers, and retailers aren’t always stellar at communicating impactful strategic changes despite sharing many of the same goals.

Growth also fuels supply chain complexity. As they scale, larger wholesalers often acquire smaller competitors. These companies often inherit the supply chain woes of their acquisitions, further complicating existing inefficiencies within their own processes.

3 ways to improve wholesale supply chain processes

Some issues facing wholesalers are the result of recent events. Yet many challenges have plagued the industry for decades and have only grown more critical as customer and consumer demand has grown — well, more demanding. If fixing the wholesale supply chain were so easy, then wholesalers would have already fixed it — right?

Many wholesalers have made terrific strides in optimizing their supply chain. These companies have leaned into data-powered supply chain planning platforms to simplify everything from forecasting and replenishment to workforce management. These planning tools offer wholesalers their clearest path toward creating a more efficient and profitable supply chain — and gaining a competitive advantage in a tough market.

If fixing the wholesale supply chain were so easy, then wholesalers would have already fixed it — right?

Wholesalers should use these digital tools to transform their supply chain in three big ways:

1. Increase automation to reduce costs

Data entry. Forecast sharing and adjustment. Inventory tracking. Capacity planning.

These tasks are essential to wholesale supply chain management, but they involve hours of monotonous work. Teams hired to gain insights from and take action on important data often sink most of their time into wrangling it instead.

Supply chain planning platforms delegate these important-but-tedious tasks to computer programs capable of executing them faster than even the most industrious worker ever could. This frees up staff to perform planning activities that computers can’t do, like strengthening customer relationships or proactively validating exceptions. Labor costs then support revenue-building behaviors instead of going toward maintaining the status quo.

2. Improve demand forecasting accuracy to minimize inventory and waste

Digital planning solutions enable wholesalers to create high-accuracy demand forecasts to maintain high availability without risking product spoilage or expiration. Products that don’t spoil or expire quickly but turn over slowly still cost wholesalers money in opportunity and storage costs.

Too often, overreliance on historical data and reorders leads to forecasting errors. Factors as varied as local weather or upcoming sporting events can influence customer demand in ways manual forecasting can’t readily predict. Wholesalers need a robust planning solution that combines historical data and reorders with external data like weather forecasts and retail point-of-sale (POS) data to improve demand forecast accuracy.

3. Enhance collaboration with suppliers, retailers, and internal teams

Constant supply chain chaos has kept teams along the supply chain consistently busy. This too often translates into poor communication, which results in missed opportunities that create even more work for sales, marketing, and operations teams.

Supply chain planning platforms uncomplicate collaboration in several big ways. Automatic forecast sharing allows wholesalers, suppliers, and retail customers to break down data silos and improve visibility. The automation of collaborative processes removes busy work while providing wholesalers with foresight into a retailer’s planned promotions or a supplier’s material shortage. Wholesalers can then adjust forecasts or prepare substitute products to improve outcomes.

4 essential supply chain planning software features for wholesalers

No single investment is likely to have a bigger impact on supply chain optimization than an upgraded supply chain planning solution. Wholesalers should ultimately seek out these four essential features before committing to an upgraded planning solution:

No single investment is likely to have a bigger impact on supply chain optimization than an upgraded supply chain planning solution.

1. Headache-free data management

Data paves the way to wholesale supply chain success. The creation of accurate demand forecasts and a digital supply chain model require great volumes of relevant data, much of which is owned by suppliers and retailers. It’s tricky enough to convince these parties to share this important data. But along the supply chain, different companies use different tools, causing wholesalers to receive data in unreadable or incompatible formats.

Wholesalers require a planning solution that wrangles their data into a form they can use to suit their needs. A worthwhile planning solution must:

- Automate data collection from internal sources, suppliers, and retailers

- Unify disparate data sets within a single platform

- Transform data into a format compatible with their existing tool stack

2. Automated & granular forecasting powered by machine learning

Any planning platform worth its salt will include automated forecasting. Planning tools will not only generate forecasts based on up-to-date data but will also adjust forecasts automatically as newer and more relevant data streams in. This allows wholesalers to stay on top of demand shifts and prevent stockouts or spoilage.

Automated forecasts are especially helpful when performed at granular levels. Wholesalers use planning tools to cluster similar accounts together and create specific forecasts for each unique segment. Worthwhile platforms also enable companies to forecast by sales and fulfillment channel to increase forecast and internal alignment.

The best planning platforms take things a step further using the power of AI. Platforms capable of machine learning analyze and react to changes at a speed and accuracy far surpassing human capabilities. The software “learns” from events, preventing planners from performing repetitive tasks and allows them to focus on improving efficiency elsewhere.

3. Supply chain digital twin

Wholesalers benefit from maintaining visibility into the entire supply chain. The sooner wholesalers identify shortages, product introductions, and supplier or retailer promotions, the sooner they can adjust their own strategies and forecasts to better meet demand.

To achieve that visibility, wholesalers need a planning solution capable of producing a digital supply chain twin. This digital twin acts as a virtual simulation of the holistic supply chain and is continuously updated with the most current and accurate data. Businesses can use the digital twin to gauge the impact of how their demand and business decisions affect the flow of goods and information throughout the supply chain.

4. Hassle-free custom configuration

Pharmaceutical wholesalers will have different customer service level needs and supplier restrictions than a wholesaler specializing in auto parts. It’s unrealistic to expect planning solutions to address every wholesaler’s individual needs right out of the box, so wholesalers must seek a planning tool that can be tailored to fit within their unique ecosystem.

But rarely does the word “easily” precede the words “configurable” and “customizable.” Wholesalers need a supply planning tool that can be configured without requiring substantial coding. It helps when the companies who make these tools are dedicated to creating a seamless integration process regardless of the challenges that arise during the process.

4 wholesale supply chain examples

Many wholesalers understand the limitations of their existing solutions but are reluctant to embrace full-scale change for fear of disruption or an underwhelming return on investment. But many wholesale businesses who have embraced digital supply chain planning solutions have already experienced wild success.

Check out how these three wholesalers have used RELEX to optimize their supply chain to impressive results:

Galexis

Swiss pharmaceutical wholesale dealer Galexis maintains a massive assortment of more than 100,000 products. The company wanted to raise inventory turnover rates while reducing general inventory levels, but their existing solution lacked the automation necessary to handle their product volume. Their merchandise management system couldn’t accurately predict for promotions and seasonality because forecasts relied entirely on static variables like historical data.

Galexis adopted RELEX company-wide after a successful three-month pilot. Increased automation of manual tasks resulted in a 46.75% increase in productivity as workers were freed up to perform more value-adding tasks. RELEX also enabled the wholesaler to build better forecasts using more dynamic parameters like store level seasonal data, achieving a 19.01% rate of inventory turnover.

JJ Foodservice Ltd.

JJ Foodservice Ltd. faced numerous challenges as an omnichannel wholesaler. The UK-based bulk food company knew supply chain inefficiencies consumed valuable staff time and negatively impacted their bottom line but was unsure of where to start with optimization efforts. The business asked RELEX to analyze their existing processes to identify the best opportunities for potential changes and then used RELEX software to improve their supply chain operations.

The analysis and subsequent changes sparked serious results. JJ Foodservice Ltd. used RELEX to efficiently and automatically factor in rule combinations to reduce order processing time by 25%. The benefits of automation extended to the company’s buyers. The wholesaler’s small buying group took advantage of the reduction in manual work to concentrate on more important tasks like fostering customer relationships or negotiating with suppliers.

RELEX also enabled the wholesaler to realize success regarding inventory management. JJ Foodservice Ltd. witnessed a 15% reduction in inventory after adopting their RELEX solution, even as they saw a 10 pp increase for fresh items over the same period.

Onninen

HVAC wholesaler Onninen needed to upgrade their supply chain to more effectively serve their customers in the Nordic countries, the Baltic states, Poland, and Russia. The wholesaler aimed to decrease general inventory levels in their central warehouse while simultaneously improving product availability.

Onninen knew this would require a system that could match the flexibility of their own supply chain processes. They also understood that these goals would require the use of planning software capable of basing replenishment ordering on up-to-date demand forecasts.

Integration with RELEX occurred over three short months. Onninen then piloted the solution with a select group of suppliers before adopting it system-wide. RELEX ultimately helped the wholesaler achieve a 25% increase in inventory turnover, a 6% increase in sales, and a 2 pp increase in product availability.

C&S Wholesale Grocers

C&S Wholesale Grocers is the largest American wholesale supply chain company, operating more than 50 distribution centers in 16 different states. In the past, the sheer scope and complexity of the company’s operations made managing forecasting and replenishment a Herculean task. But with eyes set firmly on further growth, C&S required a robust wholesale supply chain planning platform that could scale in the long term.

The company chose RELEX to address their supply chain optimization needs. The planning solution’s reputation for successful implementations was a big factor in this decision. The RELEX platform’s transparency and flexibility is helping C&S scale their inventory management and forecasting and replenishment functions efficiently, paving the way for supply chain success into the future.

Watch Sudhakar Lingineni, Chief Information Officer for C&S Wholesale Grocers, discuss the company’s relationship with RELEX

Build a better wholesale supply chain

Most wholesalers understand the need to adapt to the new reality of the supply chain or risk getting left behind. But with as many challenges as wholesalers face, it’s understandable that some may assume that there’s simply no system out there that can handle their unique problems.

RELEX is the planning solution of choice for wholesalers, manufacturers, and retailers worldwide. It’s our mission to improve sustainability and reduce waste throughout the supply chain, and our software reflects our goals. The wholesale supply chain is complex — but managing it doesn’t have to be.

Wholesale supply chain FAQ

1. What is the wholesale supply chain?

The term “wholesale supply chain” refers to the network of organizations involved in creating, distributing, and purchasing products through a wholesale intermediary. It also refers to the operations and processes used by companies to procure and ship these products. Wholesalers effectively take on a “middleman” role in the wholesale supply chain, purchasing products from suppliers or manufacturers in bulk and selling them at a low price to retail customers.

2. What are the benefits of wholesale supply chain management?

Wholesale success depends on reducing costs without sacrificing revenue. Optimization efforts iron out inefficiencies to create cost-savings opportunities throughout the supply chain by:

- Increasing inventory turnover

- Decreasing complexity

- Increasing productivity

- Improving customer satisfaction

3. How can wholesalers overcome supply chain challenges?

Shifts in supplier, retailer, and consumer demand threaten to eat away at the middle ground wholesalers have traditionally held in the supply chain. Wholesalers must reinforce their value to all parties by doubling down on the core of their appeal: the ability to move products quickly and inexpensively. Ways to reinforce this value include:

- Improving forecasting accuracy

- Building better collaborative processes with suppliers and customers

- Automating time-consuming manual tasks

Wholesalers can make these cost-saving opportunities a reality using the right supply chain planning software.