Stockmann Gains Valuable Supply Chain Insights with RELEX Solutions

Expands relationship with RELEX for supply chain diagnostics capabilities to elevate the customer experience while increasing sales.

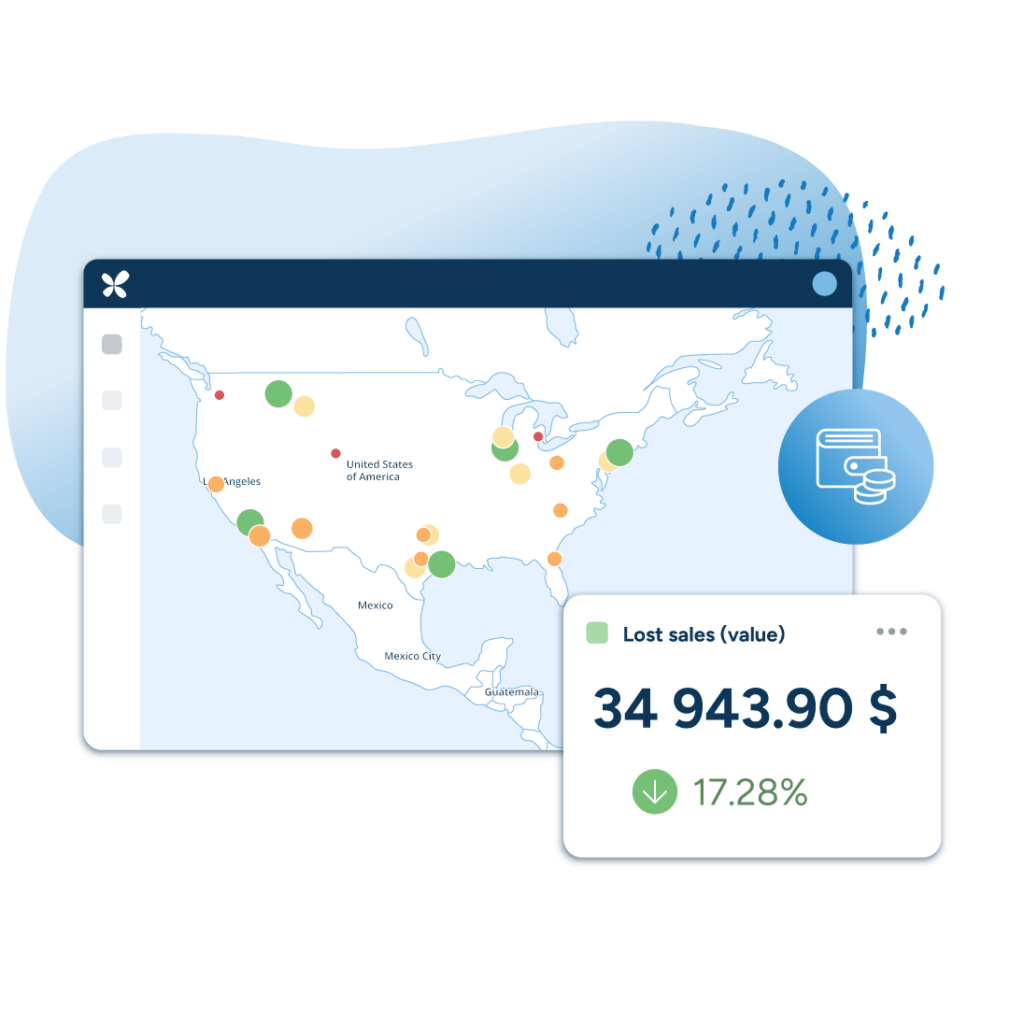

Pinpoint the root causes for stockouts, spoilage, and excess stock in stores and distribution centers. RELEX Diagnostics uses AI to analyze your data and deliver practical insights and recommendations to solve availability and waste problems, eliminating time-consuming manual analysis.

10% reduction

in lost sales

10% decrease

in spoiled quantities

2% decrease

in inventory levels

Diagnostics automates data analysis through AI and delivers insights to optimize inventory, minimize waste, and improve availability. Diagnostics provides enhanced visibility into detailed inventory breakdown and future ordering, reducing the risk of under- or over-stocking.

Key features

Quickly pinpoint the root causes of declining availability and take targeted actions to resolve issues efficiently, minimizing lost sales and improving profitability. Adjust inventory, orders, and schedules based on real data, making forecasts more accurate.

Benefits

Dashboard views provide customers with valuable insights

into their key business KPIs such as availability, inventory value, and spoilage.

RELEX Diagnostics specifies exactly why items go out of stock or go to waste, so teams don’t have to dig through spreadsheets and can instead focus on fixing problems to boost sales, keep items on shelves, and optimize inventory.

Identify what’s causing revenue-killing spoilage and stockouts, while saving your team from endless spreadsheet analysis. See immediate financial gains through better inventory levels and less waste – all without the manual number-crunching.

Identify the root causes of stockouts, spoilage, or high inventory levels and enable proactive actions to minimize lost sales and improve inventory management. Comprehensive analysis supports data-driven decisions, leading to better alignment with demand forecasts and overall supply chain efficiency.

Analyze key performance indicators (KPI) automatically, enabling store operations leaders to swiftly identify and address the root causes of stockouts, spoilage, and high inventory levels, saving significant time and effort. This leads to reduced losses, better turnover, and improved store performance and profitability.

Gain continuous visibility into detailed inventory breakdowns and root cause analysis to proactively mitigate issues related to availability, spoilage, and high inventory levels, leading to decreased lost sales and optimized inventory management across stores.

We’ve accumulated a wealth of supply chain & retail expertise from our 1,500+ planning specialists.

Retailers generate enormous amounts of data, meaning that machine learning technology quickly proves its value.

This guide demonstrates best practices for building a business case for supply chain technology investment and puts perspective on primary considerations when working with ROI calculations.

The supply chain isn’t growing simpler. It’s time for retailers and wholesalers to reevaluate their inventory planning processes.

We’re happy to discuss your business needs and share how our market-leading, unified platform can help you drive profitable growth across your sales and distribution channels. Discover why top industry analysts position RELEX as Leaders in the market.